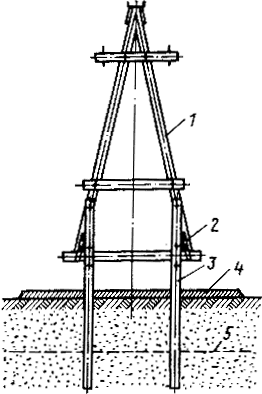

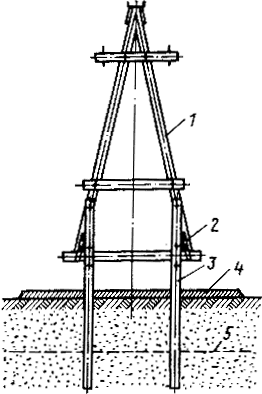

Особенности сооружения опор в сложных условиях: Сооружение ВЛ в районах с суровыми климатическими и тяжелыми геологическими условиями...

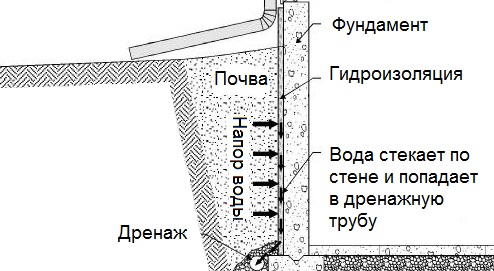

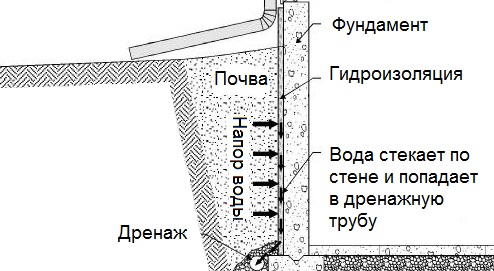

Общие условия выбора системы дренажа: Система дренажа выбирается в зависимости от характера защищаемого...

Особенности сооружения опор в сложных условиях: Сооружение ВЛ в районах с суровыми климатическими и тяжелыми геологическими условиями...

Общие условия выбора системы дренажа: Система дренажа выбирается в зависимости от характера защищаемого...

Топ:

Отражение на счетах бухгалтерского учета процесса приобретения: Процесс заготовления представляет систему экономических событий, включающих приобретение организацией у поставщиков сырья...

Процедура выполнения команд. Рабочий цикл процессора: Функционирование процессора в основном состоит из повторяющихся рабочих циклов, каждый из которых соответствует...

Теоретическая значимость работы: Описание теоретической значимости (ценности) результатов исследования должно присутствовать во введении...

Интересное:

Средства для ингаляционного наркоза: Наркоз наступает в результате вдыхания (ингаляции) средств, которое осуществляют или с помощью маски...

Подходы к решению темы фильма: Существует три основных типа исторического фильма, имеющих между собой много общего...

Распространение рака на другие отдаленные от желудка органы: Характерных симптомов рака желудка не существует. Выраженные симптомы появляются, когда опухоль...

Дисциплины:

|

из

5.00

|

Заказать работу |

Содержание книги

Поиск на нашем сайте

|

|

|

|

National and international highway systems

The Romans had realized that coordinated system of roadways connecting the major areas of their empire would be of prime significance for both commercial and military purposes. In the modern era, the nations of Europe first introduced the concept of highway system. In France, for example, the State Department of Roads and Bridges was organized in 1716, and by the middle of the 18th century the country was covered by an extensive network of roads built and maintained primarily by the national government. In 1797 the road system was divided into three classes of descending importance: (1) roads leading from Paris to the frontiers, (2) roads leading from frontier to frontier but not passing through Paris, and (3) roads connecting towns. By the early 1920s this general plan remained essentially the same except that a gradual change in class and responsibility had taken place. At that time the road system was divided into four classes: (1) national highways, improved and maintained by the national government, (2) regional highways, improved and maintained by the department under a road service bureau appointed by the Department Commission, (3) main local roads, connecting smaller cities and villages, built and maintained from funds of the communes supplemented by grants from the department, and (4) township roads, built and maintained by the communities alone.

While the British recognized the necessity for national support of highways and a national system as early as 1878, it was the Ministry of Transport Act of 1919 that first classified the roadway system into 23,230 miles of Class I roads and 14,737 miles of Class II roads. Fifty percent of the cost of Class I roads and 25 percent of the cost of Class II roads were to be borne by the national government. In the mid-1930s the need for a national through-traffic system was recognized, and the Trunk Roads Act of 1939, followed by the Trunk Roads Act of 1944, created a system of roadways for through traffic. The Special Roads Act of 1949 authorized existing or new roads to be classified as “motorways” that could be reserved for special classes of traffic. The Highway Act of 1959 swept away all previous highway legislation in England and Wales and replaced it with a comprehensive set of new laws.

The mammoth U.S. Interstate Highway System developed in response to strong public pressures in the 1950s for a better road system. These pressures culminated in the establishment by President Dwight Eisenhower of the Clay Committee in 1954. Following this committee’s recommendations, the Federal Aid Highway Act and the Highway Revenue Act of 1956 provided funding for an accelerated program of construction. A federal gasoline tax was established, the funds from which, with other highway-user payments, were placed in a Highway Trust Fund. The federal-state ratio for funding construction of the Interstate System was changed to 90 percent federal and 10 percent state. It was expected that the system would be completed no later than 1971, but cost increases and planning delays extended this time by some 25 years. The system grew to a total length of more than 45,000 miles, connecting nearly all the major cities in the United States and carrying more than 20 percent of the nation’s traffic on slightly more than 1 percent of the total road and street system.

The Canadian Highway Act of 1919 provided for a system of 40,000 kilometers (13,000 miles) of highways and provided for a federal allotment for construction not to exceed 40 percent of the cost. By the end of the century, more than 134,000 kilometers (83,000 miles) of highway had been built, of which approximately 16,000 kilometers (9,900 miles) were freeway.

In search of smoother roads

In the past concrete was considered too expensive and noisy to be an effective road surface. But that has changed – longer life, less noise is now the aim of researchers around the world.

For example, U.S. Departments of Transportation are trying to determine the rate at which concrete pavements expand and contract with temperature changes that hopefully will lead to smoother, longer-lasting roads.

The thermal coefficient of expansion test involves taking a 160 mm concrete core from pavements and measuring its length using a linear variable differential transducer.

The core is then submersed in a heating bath on a stand heated from a starting temperature of 10 oC to 50 oC. The core expands under the increase in temperature and is measured following the test to check on its rate of growth.

According to researchers, the new testing procedure will significantly improve the road design process by matching a concrete to its environment. The process could reduce the maintenance required on a stretch of road.

In the U.K. the in-service performance of concrete roads has led to the development of technologies aimed at reducing future maintenance requirements, and making the treatment of rigid pavements economic, without the need to remove the concrete.

Research has also stimulated the introduction of measures during the construction of flexible composite pavements to reduce “reflection cracking” which can allow water to enter the pavement structure and cause long-term breakdown.

Implementation of these research findings has effectively extended the design life for these types of pavements and this may encourage the increased use of concrete in future road construction.

Rigid pavements have a long design life due to their inherent strength and minimal maintenance requirements in their early life (15-20 years). After 20 years, long-term maintenance may be required. For this maintenance, the traditional method in the U.K. is to overlay with a thick asphalt layer, for example 180 mm, to inhibit the development of reflection cracking.

Reflection cracks in the asphalt surfacing, above cracks or joints in the rigid pavement, are caused by the thermal contraction of the concrete. More specifically, there are two methods that are being used by the U.K. Highways Agency in maintenance schemes on trunk roads. These are to “crack and seat” the concrete pavement prior to overlay or to “saw-cut and seal” the overlay after overlaying. Also a combination of the two may be used.

The crack and seat method is to induce fine, vertical transverse cracks in jointed un-reinforced concrete road slabs before overlaying with asphalt. This allows the seasonal contraction to take place at locations other than at the joints and reduces reflection cracking in the asphalt overlay.

The fine cracks retain the aggregate interlock necessary to ensure the satisfactory load spreading ability, while still allowing for thermal movements to take place.

In general, concrete slabs are “cracked” at 1 to 1,5 m centers using a guillotine and then “seated” using a pneumatic-tyre roller. Initially, this technique was developed for the maintenance of un-reinforced pavements but more recently the technology has been applied to reinforced concrete.

In the U.K., concrete is being used as a sub-base, particularly in “rutting” lanes. A section of the M25 was the test for an innovative CRCP (Continuously Reinforced Concrete Pavement). The major innovation here was to design the pavement on flexural strength, as opposed to using compressive strength. In this way, the full benefit of using the specified limestone (as opposed to gravel) aggregate was realized, with a saving of 40 mm of concrete thickness. The concrete was then topped with 12 mm thick stone mastic asphalt (SMA).

In the U.S., white-topping is being examined closely as a means of maintenance. It is a process in which 50 to 100 mm of high-strength, fiber-reinforced concrete is placed over a milled surface of distressed asphalt concrete pavement. This ultra-thin white-topping (UTW), has proved to be a low-cost, effective, and fairly simple solution, and is designed for low-speed traffic areas or areas with a lot of stop-and-go traffic, such as street intersections, bus stops, or toll booths. The best part is that UTW requires significantly less time to construct, and repairs last much longer. Given its success in these limited applications, UTW is now being considered for a range of other applications.

Concrete protection

Deterioration of concrete structures in aggressive environments is a major problem today. Coating the surfaces, and thereby leaving the risk of cracks in the coating, has until now solved the problems with the durability of concrete structures.

A new concept now improves the ability of the concrete to resist the ingress in aggressive elements. It deals with the problems instead of only treating the symptoms.

Road constructions are increasingly exposed to chloride ingress as a result of the steadily increasing use of de-icing salts. A weak concrete cover allows ingress of chloride ions causing corrosion of the steel reinforcement. As a result of the corrosion, the steel expands, causing spalling of the concrete structure. Enormous sums are spent on repairing concrete structures, which have been damaged as a result of the environment they are exposed to.

Insufficient focus on the importance of the concrete cover is often the main reason for deterioration of a concrete structure. The concrete cover is the outer centimeter of a construction that protects the steel reinforcement bars from aggressive elements slowly diffusing through the concrete. However, research shows that the concrete cover is often of a lower quality than the rest of the construction because the concrete surface is cast against impermeable formwork.

With the introduction of the Controlled Permeability Formwork (CPF) liner concept, focus is directed to the concrete cover. A CPF liner consists of a filter and a drainage layer. The filter faces the freshly placed concrete and the drainage layer faces the formwork. The liner is either tensioned or glued on the formwork before casting.

The concept was invented in Japan and later adopted by European manufacturers. Among the leading manufacturers of CPF in Europe are Fibertex A/S of Denmark, which markets the product under the name Formtex, and DuPont of Luxembourg.

It is internationally acknowledged fact that the lower the water/cement ratio, the stronger, denser and more penetration-resistant is the concrete.

The function of the non-woven CPF liner is to drain surplus water and air from the surface of freshly placed concrete. When water is drained off the surface, the water/cement ratio in the concrete surface is reduced and this improves the strength and durability of the concrete cover.

Several independent test reports have documented the effect of using CPF when casting concrete. CPF form liners have found a variety of uses in the European and Middle East markets. The primary usage area is concrete structures placed in aggressive environments such as road constructions, parapets, drinking water tanks, waste-water tanks, dams and marine constructions.

The CPF liner concept is gaining ground and usage is increasing steadily.

The available documentation material supports the concept as a sound alternative to the more expensive surface treatment in achieving an acceptable lifetime in aggressive environments.

|

|

|

Кормораздатчик мобильный электрифицированный: схема и процесс работы устройства...

Типы оградительных сооружений в морском порту: По расположению оградительных сооружений в плане различают волноломы, обе оконечности...

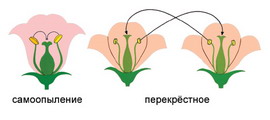

Семя – орган полового размножения и расселения растений: наружи у семян имеется плотный покров – кожура...

Археология об основании Рима: Новые раскопки проясняют и такой острый дискуссионный вопрос, как дата самого возникновения Рима...

© cyberpedia.su 2017-2026 - Не является автором материалов. Исключительное право сохранено за автором текста.

Если вы не хотите, чтобы данный материал был у нас на сайте, перейдите по ссылке: Нарушение авторских прав. Мы поможем в написании вашей работы!