Eastbourne — judging from recent buildings — is at last bursting out of its Victorian reserve. New flats, shops and restaurants, put up in the last few years, have livened the town up. The latest addition to the amenities is the Congress Theatre, commissioned by the Corporation as a building for conference and entertainment purposes. It has an auditorium with 1,640 standard seats extendable by removable seats to 2,000, and a stage suitable for plays, ballet, opera and concerts.

The theatre is built on to one end of the existing Winter Garden and is linked with it by a restaurant, so that the whole can be used as a single unit if necessary. Approached from the front, the building has a definite kinship with the Festival Hall, with a fully glazed front elevation through which the various foyers, levels and open stairways can be glimpsed. Basically, it comprises a central auditorium, 88 ft. wide and 98 ft. long, with access from foyers on three levels, and a five-storey stage block at the back.

Inside, the two levels of upper foyers, with their external glass walls, are wrapped round the back of the auditorium. They are thick-carpeted, open spaces, equipped with two bars, each with 30 to 40 ft. of counter. The levels are linked on each side of the building by wide stairs of precast terrazzo trends cantilevered from in situ reinforced concrete spine beams. These are fully expressed and structurally are very interesting to look at. The auditorium itself, with its stalls, circle and side galleries, is a spacious air place with uncluttered ceilings, plain finishes and red upholstered seating. It is lit by large double-glazed windows at each side, which can be blacked out if required, and it is hoped that this natural lighting will help to do away with “conference fatigue”. A point worth mentioning — usually nonexistent in old theatres — is the access for wheeled chairs by way of a scenery ramp, or by a lift serving all the main levels. Another interesting point is the orchestra lift in front of the stage, which can be raised to increase the size of the stage for concerts, or else sunk below auditorium floor level to form an orchestra pit.

The main frame of the auditorium and stage block is of in situ reinforced concrete. The stepping of the stalls, however, is built up of precast reinforced concrete units. Over the entrance foyer, at ground level the bones of the structure can be seen in the soffit to the rear stalls where the stepping is supported on radial beams linked by transverse members. This produces a coffered ceiling, painted in white and lime green as a decorative canopy to the entrance hall and first floor foyer. The columns of the frame are free-standing at the front and sides of the building; they are circular in plan. The tall fly tower, over the stage, juts up some 28 ft. above the main roof level, and has three walls of reinforced concrete. The erection of the frame was carried out by the general contractors very economically indeed. From the concrete point of view, the highlight of the building is undoubtedly the varied use of concrete finishes on the main elevations and in the paving. At the front and sides of the building, concrete facing blocks provide depth and texture as a foil to the large glazed areas and smoother surfaces. The blocks have a pronounced rugged texture which shows up well in the sunshine, and measure 15 in. by 6 in. by 3 in. thick. They are, in this instance, used vertically and laid in a stacked bond, forming a broad capping to the glazed front facade, which is continued round on the side elevations. Also made by this company there are the thin horizontal units of black concrete which form glazing bars round the foyers. A tribute to the precision of construction and manufacture of the main concrete elements is the fact that the whole of the glazing at the front is fixed direct to the concrete and housed only in butyl gaskets; tolerances of 1/8 in were worked to.

Also of special interest is the finish on the circular columns which form a colonnade at the front and sides. These are of natural in situ concrete cast in cardboard tubes, with a beautifully even exposed aggregate finish, achieved by the “Jason” pistol method of tooling the surface (the instrument is also used for de-scaling ships). This is a rather more delicate method of treating the concrete – particularly the matrix round the coarse aggregate – than ordinary bush-hammering. The texture of these columns is most effectively thrown up at height by small lights set flush with the paving at the base of the columns. This represents an outstanding example of exposed aggregate carried out in situ. The same surface treatment has also been applied to the facing slabs which form bands of concrete at the base of the foyer glazing, and again at a point two-thirds of the way up. Another point of interest in this area is the ribbed concrete soffit to the first floor slab, achieved by casting against plywood formwork fitted with battens.

Diaphragm walls

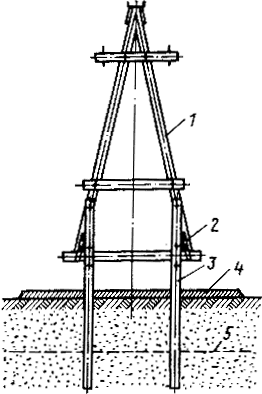

In densely built-up inner city areas the use of diaphragm walls as sheeting for deep construction pits in groundwater-bearing strata is frequently advantageous. The construction of a diaphragm wall has no adverse effects on the groundwater and causes only minimal noise and vibration. Prior to excavation of the trench, support walls, usually of in-situ concrete, are made in the upper part of the trench: they stabilize the ground in that area and at the same time serve as a locating and guiding walls for the grab.

The soil is excavated in primary and secondary sections using special grabs, while bentonite slurry supports the trench walls. First the primary sections are excavated with spacing between the slots. Stop-end tubes are then placed at both ends and the slot is reinforced and concreted. The stop-end tubes are removed as soon as the concrete begins to set and harden. The half-round vertical joints which are created this way serve as guides for the grab during excavation of the secondary sections between the primary ones and leave a close watertight contact face for the concrete of the adjacent section. The bentonite slurry is reclaimed during concreting and prepared for re-use.

If required, the prefabricated reinforcement cages can be provided with circumferential reinforcement for anchors or bracing, or with recesses and starter bars for base and floor slabs.

For the construction of precast walls, precast reinforced concrete wall elements are immersed into a hardening supporting liquid with a cement constituent. The faces are completely smooth when exposed.

Diaphragm walls can also be constructed for sealing purposes, to keep excavations dry, to render dams impermeable or to protect the groundwater near industrial plants and refuse deposits from pollution by industrial waste. In this case the stabilizing slurry, by the addition of cement and filler, becomes the sealing compound. After hardening, the compound remains sufficiently plastic to enable the wall to accept minor movements of the soil without cracking.

Both for economic reasons and in order to reduce the risk of defects in the wall (which increases with increasing depth) sealing walls are generally constructed to depths ranging from 30 to 40 m, with thicknesses varying from 0,4 m to 1,2 m.