The Modern Automobile. It is a complex technical system employing subsystems with specific design functions. Some of these consist of thousands of component parts that have evolved from breakthroughs in existing technology or from new discoveries such as electronic computers, high-strength plastics, and new alloys of steel and nonferrous metals, as well as from factors such as air pollution, safety legislation, and foreign competition.

Approximately 500 different models have been offered annually to U.S. car buyers, about half domestic and half foreign in origin. New designs have been brought into the market more quickly in recent years than in the past to permit manufacturers to capitalize on their proprietary technological advances. With more than 30 million new units built each year worldwide, manufacturers have been able to split up the total into many very small segments that nonetheless remained economical to market.

New technical developments are recognized to be the key to successful competition. Research and development engineers and scientists have been employed by all automobile manufacturers and suppliers to improve the car body, chassis, engine, drive train, vehicle control systems, occupant safety, and environmental emissions, and further work by the industry is necessary to meet the needs of the 21st century.

Vehicle design depends to a large extent on its intended use. Automobiles for off-road use in countries that lack service facilities must be durable, simple systems with high resistance to severe overloads and extremes in operating conditions. Conversely the customers for products that are intended for the high-speed, limited-access road systems in Europe and North America expect more passenger comfort options, increased engine performance, and optimized high-speed handling and vehicle stability. Stability depends principally on the distribution of weight between the front and rear wheels, the height of the centre of gravity and its position relative to the aerodynamic centre of pressure of the vehicle, suspension characteristics, and whether front or rear wheels are used for propulsion. Weight distribution depends principally on the location and size of the engine. The common practice of front-mounted engines exploits the stability that is more readily achieved with this layout. The development of aluminum engines and new manufacturing processes has, however, made it possible to locate the engine at the rear without necessarily compromising stability.

Body. Automobile body designs are frequently categorized according to the number of doors, the arrangement of seats, and the roof structure. Automobile roofs are conventionally supported by pillars on each side of the body.

Automobile bodies are generally formed out of sheet steel. Elements are added to the alloy to improve its ability to be formed into deeper depressions without wrinkling or tearing in manufacturing presses. Steel is used because of its general availability, low cost, and good workability. For certain applications, however, other materials, such as aluminum, fiberglass, and carbon-fiber reinforced plastic, are used because of their special properties. Polyamide, polyester, polystyrene, polypropylene, and ethylene plastics have been formulated for greater toughness and resistance to brittle deformation. This material has been designed successfully for some body panels.

To protect bodies from corrosive elements and maintain their strength and appearance, special priming and painting processes are used. Bodies are first dipped in cleaning baths to remove oil and other foreign matter. They then go through a successions of dip and spray cycles. Enamel and acrylic lacquer are both in common use. Electro-deposition of the sprayed paint, a process in which the paint spray is given an electrostatic charge and then attracted to the surface by a high voltage, helps assure that an even coat is applied and that hard-to-reach areas are covered, Ovens with conveyor lines are used to speed the drying process in the factory. Galvanized steel with a protective zinc coating and corrosion-resistant stainless steel are used in body areas that are more likely to corrode.

Chassis. The chassis of the modern automobile is the main structure of the vehicle. In most designs a pressed-steel frame forms skeleton on which the engine, wheels, axle assemblies, transmission, steering mechanism, brakes, and suspension members are mounted. The body is flexible bolted to the chassis during the manufacturing process. The combination of body and frame absorbs the reactions from the movement of the engine and axle, receives the reaction forces of the wheels in acceleration and braking. Absorbs aerodynamic wind forces and road shocks through the suspension, and absorbs the major energy of impact in the event of an accident.

In modern small car designs there has been a trend toward combining the chassis frame and the body into a single structural element. In this arrangement the steel body shell is reinforced with braces that make it rigid enough to resist the forces that are applied to it. Separate frames are used for other cars to achieve better noise-isolation characteristics. The presence of heavier-gauge steel components in modern separate frame designs also tends to limit intrusion in accidents.

Engine. A wide range of energy-conversion systems has been used experimentally and in automotive production. These include electric, steam, solar, turbine, rotary, and a variety of piston-type internal-combustion engines. The most successful for automobiles has been the reciprocating-piston internal-combustion engine, operating on a four-stroke cycle, while diesel engines are widely used for trucks and buses. The gasoline engine was originally selected for automobiles because it could operate more flexibly over a wide range of speeds, and the power developed for a given weight engine was reasonable; it could be produced by economical mass-production methods; and it used a readily available, moderately priced fuel — gasoline. Reliability, compact size, and range of operation later became important factors.

In late 1940s a trend began to increase engine horse-power, particularly in American models. Design changes incorporated all known methods of raising engine capacity, including increasing the pressure in the cylinders to improve efficiency, increasing the size of the engine, and increasing the speed at which power is generated. The higher forces and pressures created by these changes created engine vibration and size problems that led to stiffer, more compact engines with V and opposed cylinder layouts replacing longer straight line arrangements.

European automobile engines were of a much wider variety, ranging from 1 to 12 cylinders, with corresponding differences in overall size, weight, piston displacement, and cylinder bores. A majority of the models had four cylinders and horsepower ratings from 19 to 120. Several three-cylinder, two-stroke-cycle models were built Most engines had straight or in-line cylinders.

Fuel and lubrication. Specially formulated gasoline is essentially the only fuel used for automobile operation, although diesel fuels are used for many trucks and buses and a few automobiles. The most important requirements of a fuel for automobile use are proper volatility, sufficient antiknock quality, and freedom from polluting by-products of combustion.

All moving parts of an automobile require lubrication. Without it, friction would increase power consumption and damage the parts. The lubricant also serves as a coolant, a noise-reducing cushion, and a sealant between engine piston rings and cylinder walls. The engine lubrication system incorporates a gear-type pump that delivers filtered oil under pressure to a system of drilled passages leading to various bearings. Oil spray also lubricates the cams and valve lifters.

Cooling system. Almost all automobiles employ liquid cooling systems for their engines. A typical automotive cooling system comprises (1) a series of channels cast into the engine block and cylinder head, surrounding the combustion chambers with circulating water or other coolant to carry away excessive heat, (2) a radiator, consisting of many small tubes equipped with a honeycomb of fins to radiate heat rapidly, that receives and cools hot liquid from the engine, (3) a centrifugal-type water pump with which to circulate coolant, (4) a thermostat, which maintains constant temperature by automatically varying the amount of coolant passing into the radiator, and (5) a fan, which draws fresh air trough the radiator.

Coolants contain corrosion inhibitors designed to make it necessary to drain and refill the cooling system only once a year.

Air-cooled cylinders operate at higher, more efficient temperatures, and air cooling offers the important advantage of eliminating not only freezing and boiling of the coolant at temperature extremes but also corrosion damage to the cooling system. Control of engine temperature is more difficult, however, and high-temperature-resistant ceramic parts are required when design operating temperatures are significantly increased.

Transmission. The transmission is such a speed-changing device. It is installed in the power train that connects the crankshaft of the engine to the driving wheels. This permits the engine to operate at a higher speed when its full power is needed and to slow down to a more economical speed when less power is needed. Under some conditions, as in starting a stationary vehicle or in ascending steep grades, the torque of the engine is insufficient, and amplification is desirable. Most devices employed to change the ratio of the speed of the engine to the speed of the driving wheels multiply the engine torque by the same factor by which the engine speed is increased.

The simplest automobile transmission is the sliding-spur gear type with three or more forward speeds and reverse. Most automatic transmissions employ a hydraulic torque converter, a device for transmitting and amplifying the torque produced by the engine. Each type provides for manual selection of reverse and low ranges that either prevent automatic upshifts or employ lower gear ratios than are used in normal driving. Grade-retard provisions are also sometimes included to supply dynamic engine braking on hills.

The transmission control unit is interconnected with the vehicle’s emission control unit to permit the engine timing and air-to-fuel ratio to be momentarily tailored to optimize the control of exhaust emission chemistry during the transmission shift cycle.

Small, low-powered cars usually have manually shifted, five-speed transmissions. Fully automatic transmissions are used for the most part in larger cars with ratings above 60 horsepower.

VOCABULARY NOTES

chassis шасси, ходовая часть

engine двигатель

piston-type internal combustion engine двигатель внутреннего сгорания

reciprocating engine поршневой двигатель

wheel колесо

front (back-rear) wheel переднее (заднее) колесо

wheel broke колёсный тормоз

wheel assembly колёсное шасси

wheel drive привод колёс

wheel load давление на колесо

to suspend вешать, подвешивать

suspension members подвесные части

propulsion движущая сила; движение вперёд (назад)

priming заправка (двигателя)

succession последовательность

electro - deposition гальваническое покрытие

electrostatic charge электростатический заряд

axle ось, вал

steering mechanism рулевое управление

stroke ход (поршня, клапана)

camshaft распределительный вал

lubrication смазка

friction трение

cushion (техн.) подушка

fan вентилятор

train зубчатая передача; система рычагов

crankshaft коленчатый вал

torque редуктор

gear ratio передаточное число

middle (to, bottom, first …) gear средняя (высшая, самая малая, первая) скорость

reverse gear задний ход

to put into (out of) gear включать (выключать) передачу

to be tailored приспосабливаться

EXERCISES

I. Read and translate the following text.

II. Find Russian equivalents to the English ones:

| engine

| заднее колесо

|

| chassis

| редуктор

|

| front wheel

| вентилятор

|

| rear wheel

| система рычагов

|

| axle

| шасси

|

| camshaft

| трение

|

| friction

| переднее колесо

|

| train

| двигатель

|

| torque

| ось, вал

|

| fan

| распределительный вал

|

III. Answer the following questions:

1. What are the main parts of the vehicle?

2. What does the vehicle design depend on?

3. Why is steel used for automobile bodies?

4. What other materials are used for automobile?

5. Why is chassis the main structure of the vehicle?

6. What types of engines can you name?

7. Why do you think the gasoline engine was selected for automobile?

8. What kind of fuel is used for automobile operation? Why?

9. Why do all moving parts require lubrication?

10. What are the main types of cooling systems?

11. What is the simplest automobile transmission?

IV. Make up a brief summary of the text.

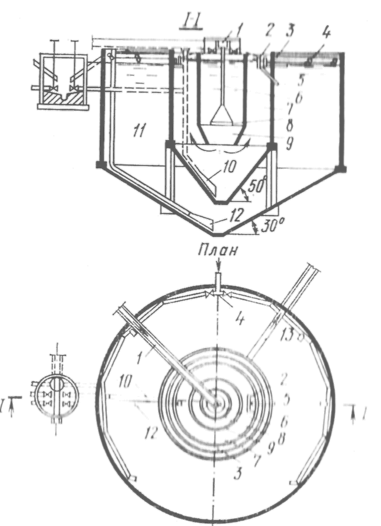

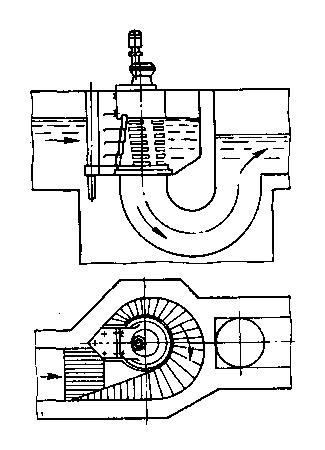

A CAR COOLING SYSTEM

Most car engines are cooled by water. The water flows around the engine and then passes through the radiator. It then passes through the water pump and around the engine again.

Most car engines are cooled by water. The water flows around the engine and then passes through the radiator. It then passes through the water pump and around the engine again.

Here are the stages:

1. Water flows around the engine. The engine is cooled and the water is heated.

2. The hot water enters the radiator through the top hose.

3. It flows down through the radiator. Here it is cooled by air.

4. The cool water leaves the radiator through the bottom hose.

5. The water is pumped around the engine again.

Look at FIG. 3. Air is pulled through the radiator by a fan. This fan is turned by a belt, which is driven by the engine.

EXERCISES

I. What are the objects in the diagrams called?

Example: (a) is called a radiator.

II. Answer these questions:

1. Look at Fig. 2. Is the water hot or cold at point (1)? At point (2)?

2. What cools the engine?

3. What makes the water hot?

4. What makes the water cool?

5. What pumps the water round the engine?

6. What pulls air through the radiator?

7. What does the belt turn?

8. What drives the belt?

FUEL WARNING LIGHT

Many cars have a fuel warning light. When the level of fuel (petrol) in the tank is very low, this light switches on and the driver can see that he needs more petrol. How does this light work?

When the level of the fuel falls, the float moves downwards. When this happens, the arm also moves downwards and makes the lever touch an electrical contact. This switches on the fuel light in the car.

When the driver sees the fuel warning light, he puts more petrol into the tank. This makes the fuel level rise and pushes the float upwards. When the float rises, it makes the arm move upwards and this causes the lever to move upwards also. The fuel warning light then switches off.

EX Е RCISES

I. Read the text and follow the information.

II. What do the letters in the diagrams refer to? (Look at the words in italics in the passage.)

Example: (a) This is called a light,

III. Answer these questions:

1. When does the fuel warning light go on?

2. Why does the float go down?

3. What makes the lever move downwards?

4. Does the float go up or down when the fuel level rises?

5. When does the lever move upwards?

TEST I

I. Give the Russian for:

highway

macadam road surface

pavement

turnpike

network

truck

van

car safety features

drive in(s)

toll road

mobile

engine

wheel

axle

steering mechanism

II. Translate into Russian:

1. Modern highway design entails careful study of soil, the topography of the intended route, and the drainage systems around the roadway.

2. Road traffic accidents have become a particular problem in Great Britain.

3. A new type of engine for sports cars will have been produced by the end of the year.

4. The company offers road pavers on crawlers and on wheels, with diesel-hydraulic or diesel-electric drive systems.

5. New forms of city transport may involve buses on specially constructed reserved tracks.

6. A mobile road safety barrier, developed in Germany, has been used to provide traffic management on road repair project.

7. Macadams made with tar have been used for many years for surfacing lorry parks and depots because the solvency effect of light petroleum residues on tar is minimal.

8. The national expressways which are fully access controlled must be frequently separated from other crossing roads.

9. Transportation problems of the big cities can be solved by better organization of conventional means of transport.

10. The automobile has been described as either a menace to civilization or a symbol of personal freedom.

TEST II

I. Give the Russian for:

carriage

vehicle

filling station

freight

straight truck

articulated truck

coupling

coach

crankshaft torque

friction

rigid pavement

lubrication

facilities

sub-grade

reciprocating engine

II. Translate into Russian:

1. India has the third largest road network in the world.

2. For new roads, our products help stabilize soil, provide drainage, and separate layers of stone from sub-grades.

3. A flexible pavement has the advantage of being easy to build and repair, its asphalt binder is both waterproof and plastic.

4. A single overweight truck passing over a section of roadway can cause more damage than an entire day’s volume on a typical interstate highway.

5. To use more glass in a modern motor vehicle means improvement of visibility.

6. Demand for road transport in Europe has constantly outpaced the development of the road network, in particular for motorways and express links.

7. A driver must not assume that a car’s engine, brakes, lights and steering system always operate properly.

8. Axle assemblies of heavy trucks may be made up of two or more axles, any of which may be powered.

9. The simplest automobile transmission is the sliding-spur gear type with three or more forward speeds and reverse.

10. Surely no one will disagree that the car has given millions of people more options of where to live and work and opened up greater access to social and economic opportunity.

Most car engines are cooled by water. The water flows around the engine and then passes through the radiator. It then passes through the water pump and around the engine again.

Most car engines are cooled by water. The water flows around the engine and then passes through the radiator. It then passes through the water pump and around the engine again.