The relevance of this study lies in the fact that this topic has not received sufficient coverage in the literature. We decided to study the impact of the selected modes and the grain size of the drills used on the roughness of the resulting channels. Since a large number of surface defects inside the drilled channels appear at the next stage of an optical fiber production, air voids may be formed around the rods inserted into the channels. The result of fusion in the form of a cross-section drawn from an anisotropic fiber preform is shown in Fig. 1 a.

|

|

| a)

| b)

|

| Figure 1 - Appearance of an anisotropic fiber as a result of fusion of the preform with the loading rods: a) - the formation of air voids around the loading rods; b) - elimination of air voids around the loading rods.

|

These defects as a whole are assessed through the roughness of the surface. The roughness of the surface is determined by the height, shape and location of surface irregularities and depends on the processing technology of silica glass, the feed rate of the drill, the speed of rotation, the pressure of the cutting fluid and the quality of the tool used [3].

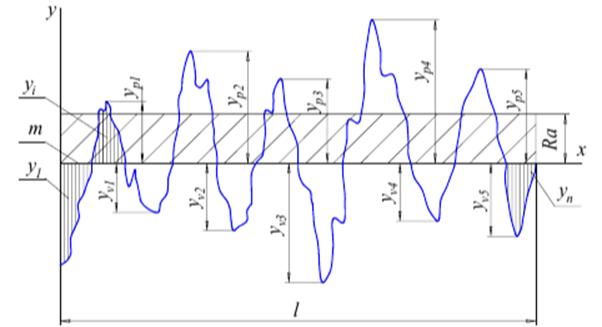

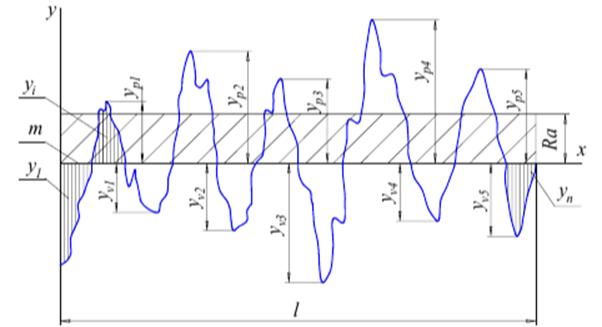

To assess the parameters of the surface profile, it is touched with a special diamond needle of the profillograph. Several lines are plotted on the obtained profile: a mid-line m, the base having the form of a nominal profile, lines of protrusions and depressions with the maximum sizes relative to the base, ypi and yνi, respectively, where i is the number of the protrusion or depression (Fig. 2). To separate the surface roughness from the other irregularities (deviations in shape and waviness) with relatively large steps, it is considered within a limited area of the base length l. The arithmetic mean deviation of the profile, Ra, and the maximum height of the profile, Rmax, are taken as the results of measurements.

|

| Figure 2 - Surface profile

|

To research the effect of the selected drilling modes and drill grain size, silica glass preforms made by MCVD technology were used. The channels in the preforms were drilled on Sonic Mill equipment (USA) using diamond drills of the same diameter and different grain sizes - 125/100 and 100/80. For drilling, linear feed rate, drill rotation, and pressure of the cutting fluid remained the same. To assess the roughness of the channels in the preform, we used the contact roughness evaluation method using a Taylor Hobson 5.0 profillograph (Great Britain). The results are shown in Table 1.

Table 1 - Results of surface roughness measurements

|

| Drill with 100/80 grain size

| Drill with 125/100 grain size

|

|

| Ra

| Rmax

| Ra

| Rmax

|

| Minimum

| 0.06

| 0.08

| 0.24

| 1.18

|

| Maximum

| 0.08

| 2.36

| 0.43

| 2.05

|

| Average

| 0.07

| 1.58

| 0.35

| 1.62

|

| Roughness class

| 11

| 8

|

The greatest surface damage inside the drilled holes is caused by the use of a drill with a larger grain size 125/100, in which the arithmetic mean deviation of the Ra profile is five times that of a 100/80 drill. The Rmax is comparable for both drill grain sizes. The roughness class according to GOST 2789-73 [1] was 8 with the 125/100 drill.

Then we selected additional preforms made of silica glass and increased the pressure of the cutting fluid during drilling by 30%. The results are shown in Table 2.

Table 2 - Results of surface roughness measurements

|

| Drill with 100/80 grain size

| Drill with 125/100 grain size

|

|

| Ra

| Rmax

| Ra

| Rmax

|

| Minimum

| 0.06

| 0.81

| 0.06

| 0.82

|

| Maximum

| 0.09

| 2.94

| 0.09

| 2.5

|

| Average

| 0.08

| 1.88

| 0.08

| 1.66

|

| Roughness class

| 10

| 10

|

Regardless of the grain size of the diamond drill used, the result was the same in both cases. The roughness class according to GOST 2789-73 [1] was now 10.

A preform with the best channel roughness class was selected and fused with loading rods. The result of fusion was confirmed by the elimination of the air voids formation around the rod (Fig. 1 b).

Conclusion

The research work carried out showed that the use of a diamond drill with a smaller grain size and with a lower pressure of the cutting fluid made it possible to reduce the arithmetic mean deviation of the profile Ra to 0.07, at which the roughness class corresponds to 11 according to GOST 2789-73 [1]. The result obtained should be confirmed by additional tests and refinement of the drilling modes in order to reduce the roughness. In the course of research, additional objectives in this area have been identified. One of them is the modeling of the surface inside the channels as a method of non-destructive testing of silica glass preforms. The second objective is the study of the impact of increased roughness on the operation of devices, in which one of the main components is optical fiber.

Acknoledgement

Research work was carried out at the production site of Perm Scientific and Production Instrument-Making Company. I also express my deepest gratitude to the engineers - technologists of the Optical Components Production Plant and V. I. Saburov, the quality engineer of the technical control department.

R eference list

1. ГОСТ 2789-73 Шероховатость поверхности. Параметры и характеристики : (с изменениями № 1, 2, утвержденными в мае 1980 г.) : утвержден и введен в действие Постановлением Государственного комитета стандартов Совета Министров СССР от 23 апреля 1973 г. № 995 : дата введения 1975-01-01. – Текст : электронный // Техэксперт : электронный фонд правовой и нормативно-технической документации. – URL: http://docs.cntd.ru/document/1200003160 (дата обращения: 01.04.2021).

2. Бейли, Д. Волоконная оптика: теория и практика / Дэвид Бейли, Эдвин Райнт. – Москва : КУДИЦ-ОБРАЗ, 2006. – 320 с.

3. Маркова, Т. В. Шероховатость поверхности : методические указания / Т. В. Маркова, И. М. Крыжановская. – Санкт-Петербург : Издательство Политехнического университета, 2006 – 32 с.

4. Патент № 2062257 Российская Федерация, МПК С03В37/00. Заготовка для одномодового волоконного световода, сохраняющего поляризацию излучения : № 4529324/33 : заявл. 09.04.1990 : опубл. 20.06.1996 / Курбатов А. М., Зуев А. И., Голяков Е. – Текст : электронный // Национальная электронная библиотека. – URL: https://viewer.rusneb.ru/ru/000224_000128_0002062257_19960620_C1_RU?page=1&rotate=0&theme=white (дата обращения: 25.03.2021).

| E.A. Pershin, E.A. Farberova, N.B. Hodyashev

| Е. А. Першин, Е. А. Фарберова, Н. Б. Ходяшев

|

| Perm National Research Polytechnic University

| Пермский Национальный Исследовательский Политехнический Университет

|

| Research into the effect of raw material grinding on the quality of granular activated carbon

| Исследование влияния измельчения сырья на качество гранулированного активированного угля

|

| Abstract: The paper presents a brief overview of granular activated carbon production. The adsorption characteristics of granular activated carbons obtained from carbon raw materials of various grinding degrees have been studied. The effect of raw material grinding on the quality characteristics of granular activated carbons is shown.

| Аннотация: В работе представлен краткий обзор производства гранулированного активированного угля. Изучены адсорбционные характеристики гранулированного активированного углерода, полученного из углеродного сырья различной степени измельчения. Показано влияние измельчения сырья на качественные характеристики гранулированных активированных углеродов.

|

Keywords: granular activated carbon, carbon-containing raw material, binder

Introduction

Granular activated carbons (GAC) are black or gray-black cylindrical granules obtained from carbon-containing raw materials (coal, peat, vegetable raw materials, etc.) and a binder by preparation of the composition with subsequent granulation, carbonization and activation [1]. GAC are used to purify drinking water, household and industrial effluents, various solutions, syrups in the chemical, food, and pharmaceutical industries, gas and air emissions, process gases, as well as to capture solvent vapors, to fill household and industrial filters, and as a basis for various catalysts and absorbers [3].

The production process of granular activated carbons includes the following stages:

• Crushing and grinding of carbon-containing raw materials in crushers and ball mills, with subsequent screening of the milled particles into fractions.

• Preparation of a binder and coal-resin composition (CRC) by mixing the binder components (coal or wood-chemical resins) with subsequent addition of the ground carbon-containing raw materials.

• Shaping of granules in various ways: by extrusion with a screw or hydraulic granulator through the dies of a given size, then pressing and dispersing.

• Drying the obtained granules.

• High-temperature treatment of granules in an inert (carbonization) and oxidizing (activation) environment of drum or shaft furnaces [2].

An important stage of GAC production is grinding of raw coal because the degree of its grinding and composition homogeneity of the dust-like particles can significantly affect the technological parameters of GAC production and characteristics of the resulting active product. To produce GAC with desired characteristics, it is necessary to study the effect of the raw coal fractional composition on GAC production characteristics and its quality. This fact implies carrying out a number of experiments to study GAC adsorption characteristics, depending on the degree of raw coal grinding. These characteristics include:

• true and envelope density,

• specific volume and size of pores.

The results of the experiments will give an opportunity to identify the dependence of GAC quality on the degree of raw coal grinding and to produce GAC with specified parameters.

Relevance of the study is determined by lack of data that allow obtaining GAC of specified parameters to meet the needs of industry. Thus, the study is aimed at identifying technological parameters for the production of GAC with the specified characteristics.

Materials and methods