Семя – орган полового размножения и расселения растений: наружи у семян имеется плотный покров – кожура...

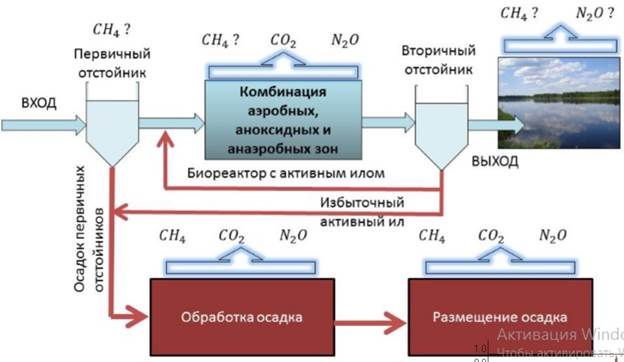

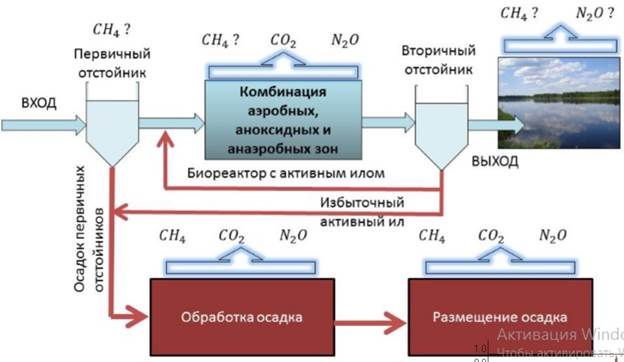

Эмиссия газов от очистных сооружений канализации: В последние годы внимание мирового сообщества сосредоточено на экологических проблемах...

Семя – орган полового размножения и расселения растений: наружи у семян имеется плотный покров – кожура...

Эмиссия газов от очистных сооружений канализации: В последние годы внимание мирового сообщества сосредоточено на экологических проблемах...

Топ:

Техника безопасности при работе на пароконвектомате: К обслуживанию пароконвектомата допускаются лица, прошедшие технический минимум по эксплуатации оборудования...

Устройство и оснащение процедурного кабинета: Решающая роль в обеспечении правильного лечения пациентов отводится процедурной медсестре...

Установка замедленного коксования: Чем выше температура и ниже давление, тем место разрыва углеродной цепи всё больше смещается к её концу и значительно возрастает...

Интересное:

Что нужно делать при лейкемии: Прежде всего, необходимо выяснить, не страдаете ли вы каким-либо душевным недугом...

Инженерная защита территорий, зданий и сооружений от опасных геологических процессов: Изучение оползневых явлений, оценка устойчивости склонов и проектирование противооползневых сооружений — актуальнейшие задачи, стоящие перед отечественными...

Берегоукрепление оползневых склонов: На прибрежных склонах основной причиной развития оползневых процессов является подмыв водами рек естественных склонов...

Дисциплины:

|

из

5.00

|

Заказать работу |

|

|

|

|

If a porous solid is exposed to a gas or vapors it adsorbs the gas onto its surface, more specifically, into its pores. The solid is considered to be an adsorbent, while the gas or vapor is considered to be the adsorbates. During adsorption, mainly two forces acting between the solid and the gas molecules. The first is a physical force, Van-der-Waals, and the other is a chemical force. Given this assumption, it can be claimed that adsorption as such involves both physical and chemical adsorption (Cal 1995).

As a result of physical adsorption, the adsorption of gas molecules increases as the temperature drops and pressure decreases. An adsorption isotherm shows the quantity of adsorbate as a function of partial pressure P/Po. On the whole, there are six types of isotherms which indicate the porosity of the adsorbent (Sattler 2010).

Research Objectives

The objective of this research was to investigate the methods to produce high quality activated carbon when using LUKOIL Petroleum Delayed Coke as a precursor. As noted above, this sort of coke is regarded either as industrial waste, or it is used in a way which is irrational and, consequently, not cost-efficient. That is why petroleum coke utilization and upgrading the by-product of crude oil processing with the view to obtaining the product which is in great demand on the market is believed to be an urgent problem.

To the current moment, we have performed physical activation by using overheated water vapor and а muffle furnace heating. As result, we obtained active carbon, which have surface area about 400 m2/g.

Reference list

1. A microscopic view of physical and chemical activation in the synthesis of porous carbons / J. I. Paredes, F. Suárez-García, A. Martínez-Alonso, J. M. D. Tascón // Langmuir. 2006. № 22 (23). P. 30–39.

2. Ajayi, O. A. A comparative study of thermal and chemical activation of Canarium schweinfurthii Nutshell / O. A. Ajayi, A. S. Olawale // Journal of Applied Sciences Research. 2009. № 5 (12). P. 2148–2152.

3. Bansal, R. C. Active carbon / Roop Chand Bansal, Jean Baptiste Donnet, Fritz Stoeckli. – New York ; Basel : Dekker, Cop, 1988. – XIV, 482 p. : il. – ISBN 0-8247-7842-1.

4. Functional Nanomaterials : handbook of Nanophysics / Edited byK. D. Sattler. – Boca Raton : CRC Press, 2010. – 787 p. – ISBN 9781138111936.

5. Cal, M. P. Characterization of gas phase adsorption capacity of untreated and chemically treated activated carbon cloths : speciality «Engineering ecology in construction» : doctor of philosophy thesis/ M. P. Cal ; [place of defence: University of Illinois at Urbana-Champaign]. – Illinois, 1995. – 99 p. – URL: https://www.mobt3ath.com/pdf.php?ext=pdf&id=37221&tit=Cal_Mark_P.Characterization_of_gas_phase_adsorption_capacity_of_untreated_and_chemically_treated_activated_carbon_cloths (date accessed: 02.05.2020). – Text : electronic.

6. Guo, J. Preparation of activated carbons from oil-palm- stone chars by microwave-induced carbon dioxide activation / J. Guo, A. C. Lua // Carbon. 2000. № 38 (14). P. 1985–1993.

|

|

7. Jankowska, H. Active carbon / H. Jankowska, A. Świątkowsk, J. Choma. – Harlow : Ellis Horwood Ltd, 1991. – 278 p.

8. Prakash, J. Prediction of activated carbon adsorption isotherms for organic vapors / J. Prakash, N. Nirmalakhandan, R. E. Speece // Environmental Science and Technology. 1994. № 28 (8). P. 1403–1409.

9. Preparation and characterization of activated carbon from date stones by physical activation with steam / C. Bouchelta, M. S. Medjram, O. Bertrand, J. P. Bellat // Journal of Analytical and Applied Pyrolysis. 2008. Vol 82, № 1. P. 70–77.

10. Preparation of high surface area activated carbon from coconut shells using microwave heating / Kunbin Yang, J. Peng, C. Srinivasakannan [et al.] // Bioresource Technology. 2010. № 101(15). P. 61–69.

11. Preparation of porous carbons from petroleum coke by different activation methods / M. Wu, Q. Zha, J. Qiu [et al.] // Fuel. 2005. № 84 (14–15). P. 1992–1997.

12. Removal of SOx and NOx over activated carbon fibers / I. Mochida, Y. Korai, M. Shirahama [et al.] // Carbon. 2000. № 38 (2). P. 227–239.

13. Wang, T. Preparation and characterization of activated carbon from wood via microwave-induced ZnCl2 activation / T. Wang, S. Tan, C. Liang // Carbon. 2009. V. 47, № 7. P. 1880–1883.

14. Williams, H. M. Activation of a phenolic resin- derived carbon in air using microwave thermogravimetry / H. M. Williams, G. M. B. Parkes // Carbon. 2008. V. 46, № 8. P. 1169–1172.

| Anna Mikhailova | Анна Михайлова |

| Perm National Research Polytechnic University | Пермский Национальный Исследовательский Политехнический Университет |

| Selection of Reagents for Local Wastewater Treatment in Pulp and Paper Industry | Отбор реагентов для местной очистки сточных вод. в целлюлозно-бумажной промышленности |

| Abstract: The article presents the results of studying and selecting reagents for local wastewater treatment in pulp and paper production. The impact of iron (II) sulfate and iron (III) chloride on wastewater treatment was studied, the optimal conditions of treatment were determined. As experimental data show, wastewater is most effectively treated to remove lignosulfonates, suspended solids and sulfur-containing compounds when they are exposed to a coagulant - iron sulfate and cationic flocculant - Praestol. | Аннотация: В статье представлены результаты изучения и отбора реагентов для местной очистки сточных вод при производстве целлюлозы и бумаги. Изучалось воздействие железа (II) сульфата и железа (III) хлорида на очистку сточных вод, были определены оптимальные условия обработки. Как показывают экспериментальные данные, сточные воды наиболее эффективно обрабатываются для удаления лигносульфонатов, взвешенных твердых веществ и соединений, содержащих серу, когда они подвергаются воздействию коагулянта - сульфата железа и катионного флокулянта – праестола. |

Keywords: pulp and paper production, wastewater, sulfur-containing compounds, optimal dose of reagent, coagulation.

|

|

Introduction

Pulp and paper production is one of the leaders in terms of water consumption and water disposal in the Russian Federation, and this is especially typical of the Perm Territory, where a number of large paper and paperboard manufacturers operate. When it comes to environmental impact, this industry turns out to be a great source of toxic air emissions and water discharges [2]. Pulp and paper industry wastewater has a high content of suspended solids, sulfates, nitrates, nitrites, phosphates, organic substances (BOD, COD), including bioresistant lignosulfonic acids and lignosulfonates [1,4].

Enterprise wastewater is traditionally subjected to mechanical and biological treatment at plant-wide treatment facilities of an open type. The treatment process is also accompanied by emissions of sulfur-containing compounds.

High content of bioresistant impurities in wastewater, such as lignosulfonic acids and lignosulfonates, does not allow the required quality of treated water. In this regard, the development of methods for treating sulfur and lignin-containing compounds in pulp and paper industry wastewater is relevant [3]. The coagulation method is relatively widely used to treat high-molecular compounds in industrial wastewater.

As the literature review shows, inorganic compounds of aluminum, iron (II) and (III), magnesium and other metals possess coagulating abilities [4]. Water treatment with mineral coagulants - aluminum and iron salts - was first applied at the turn of the XIX – XX centuries. Since then, this method has been successfully used for treating natural and wastewater and it is still preferred despite the fact that other coagulants, such as magnesium and calcium salts, were offered [5].

It is known that flocculants are used to increase the efficiency of coagulation wastewater treatment. Flocculation gained wide practical application in water treatment technologies in the 1930s. Currently, flocculation is widely used in industrial and domestic wastewater treatment technology [6].

The aim of the study was to substantiate the selection of reagents for wastewater treatment to remove sulfur-containing compounds, suspended solids and lignosulfonates released by the Perm region pulp and paper mills. To achieve this goal, the following tasks were set:

1. Experimental substantiation of reagents selection for adjusting wastewater pH in order to reduce the emissions of hydrogen sulfide;

2. Selection of the most effective reagents for wastewater treatment to remove sulfur-containing compounds;

3. Research into treatment of wastewater to remove lignosulfonates, sulfur-containing compounds and suspended solids using coagulation and flocculation methods. Selection of coagulants and flocculants, and determination of their optimal dose.

Methods and Materials

Materials

When conducting the research, iron (II) sulfate and iron (III) sulfate were chosen as the reagents, since they are able to form sparingly soluble compounds with sulfide ions (HS- + Fe2+= FeS+H+, 2HS-+Fe3+=FeS+S+H+, 3HS-+2Fe3+=Fe2S3+3H+), and have a coagulation ability.

The interaction of hydrogen sulfide with iron (III) hydroxide can be represented by the reactions:

2Fe(OH)3 + 3 H2S = Fe2S3 + 6H2O;

2Fe(OH)3 + H2S = 2FeS + S + 6H2O.

Solutions of sodium hydroxide (1 mol / dm3) and hydrochloric acid (1 mol / dm3) were used to adjust the pH of the studied water.

Experimental Techniques

|

|

|

История создания датчика движения: Первый прибор для обнаружения движения был изобретен немецким физиком Генрихом Герцем...

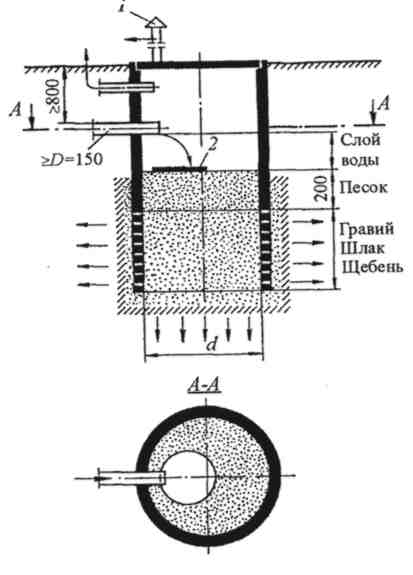

Индивидуальные очистные сооружения: К классу индивидуальных очистных сооружений относят сооружения, пропускная способность которых...

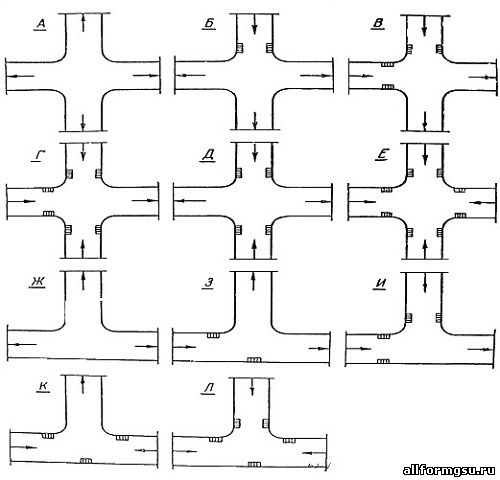

Организация стока поверхностных вод: Наибольшее количество влаги на земном шаре испаряется с поверхности морей и океанов (88‰)...

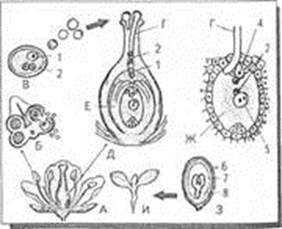

Двойное оплодотворение у цветковых растений: Оплодотворение - это процесс слияния мужской и женской половых клеток с образованием зиготы...

© cyberpedia.su 2017-2024 - Не является автором материалов. Исключительное право сохранено за автором текста.

Если вы не хотите, чтобы данный материал был у нас на сайте, перейдите по ссылке: Нарушение авторских прав. Мы поможем в написании вашей работы!