Кормораздатчик мобильный электрифицированный: схема и процесс работы устройства...

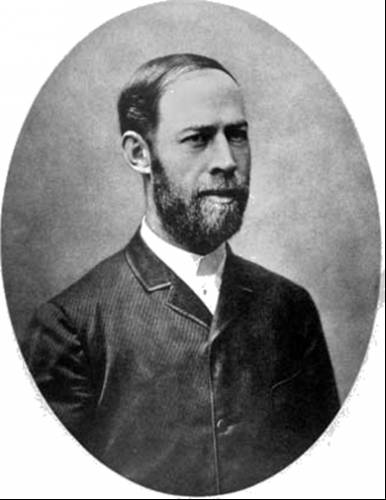

История создания датчика движения: Первый прибор для обнаружения движения был изобретен немецким физиком Генрихом Герцем...

Кормораздатчик мобильный электрифицированный: схема и процесс работы устройства...

История создания датчика движения: Первый прибор для обнаружения движения был изобретен немецким физиком Генрихом Герцем...

Топ:

Отражение на счетах бухгалтерского учета процесса приобретения: Процесс заготовления представляет систему экономических событий, включающих приобретение организацией у поставщиков сырья...

Основы обеспечения единства измерений: Обеспечение единства измерений - деятельность метрологических служб, направленная на достижение...

Характеристика АТП и сварочно-жестяницкого участка: Транспорт в настоящее время является одной из важнейших отраслей народного...

Интересное:

Средства для ингаляционного наркоза: Наркоз наступает в результате вдыхания (ингаляции) средств, которое осуществляют или с помощью маски...

Подходы к решению темы фильма: Существует три основных типа исторического фильма, имеющих между собой много общего...

Как мы говорим и как мы слушаем: общение можно сравнить с огромным зонтиком, под которым скрыто все...

Дисциплины:

|

из

5.00

|

Заказать работу |

Unit 1: PrePress

Mr Jason is introducing Liza to her colleagues from the pre-press department. Liza wants to become a media-operator. Her training takes 3 years and she’s going to work in every department of MasterPrint.

Welcome Liza

Mr Jason: Good morning everybody! I want to introduce you to Liza

Ivanova. She’s the new media-operator-trainee.

Liza: Hello.

Jennifer Pears: Hello Liza, we are the pre-press team. My name is Jennifer, I work at the scanstation and this is Barbara, she knows everything about data-transfer.

Barbara Brown: How are you? Why do you want to become a media-operator?

Liza: My uncle works as a printer in a gravure-printhouse. He told me a bit about his work.

Mr Jason: Our printing method is offset. The workflow is different from gravure.

Ethan Bootman: Hi Liza, my name is Ethan. I do all kinds of jobs in this department. I work especially for the administration, that means that I’m responsible for linking hardware and taking care of the software on each computer. Don’t be afraid, I think we will be a good team.

Mr Jason: I see, you will be well taken care of here – well, I go back to my work. Ask me if you have any questions or tell me if you have any problems. See you.

Barbara Brown: That’s your computer. It is an Apple Macintosh. Have you ever worked with computers before?

Barbara Brown: That’s your computer. It is an Apple Macintosh. Have you ever worked with computers before?

Liza: Yes, I wrote letters with MS Word and I printed out my holiday photos. I have a Pentium III at home.

Barbara Brown: Perfect. I will show you how to handle the different programs. But now take a seat and watch me. We’ll start your training with easy jobs and we will increase it every day.

Jennifer Pears: If you have any kind of questions – just ask. We will help you.

Barbara Brown: And now let’s have a cup of coffee…

More about this topic

Questions about the text

1. Who’s Liza?

2. What did Mr Jason do?

3. What are the different jobs of the people in the pre-press department?

4. Has Liza ever worked with Macintosh computers?

5. Where does Liza’s uncle work? What kind of job does he do?

Talk about it

Do you remember? What happened at your first day as a trainee?

You can use the sentences in the box as an example.

| I saw… | My parents told me… |

| Someone told me to make/go… | I learned… |

| My workstation was… | I was frightened because… |

| The colleagues were… | I just sat on the chair because… |

| I hoped that… | |

| The introduction started with… |

All about words

Explain in your own words

data-transfer department

administration gravure

printing company scan-station

Draw a mind-map

| Printing methods |

| offset |

| gravure |

More about this topic

Questions about the text on page 8 and 9

1. Who has a personal weakness for coffee? 8. Who wants to study again?

2. Why should all machines be utilized? 9. Which people play soccer?

3. What is the order structure like today? 10. Why does Liza want to

4. Who is responsible for the trainees? become a media-operator?

5. Which machine is old?

6. What is the problem of the bindery?

7. What are Mr Jason’s hobbies?

Teamwork

Introduce yourself. The us something about your private life, your job. Or do you have an interesting hobby? Tell us a short story.

Tip: You can link the nouns in the green box with the adjectives in the yellow box.

For example: I am a printer. My hobby is taking photos. This is great because I like to spend my time in the nature.

| employer raters skill picture holiday critics weakness hobby job art experience present cemera |

| interesting bad good useful genuine friendly complicated nature best great relaxing funny |

All about words

Link the opposites

Look at the adjectives in the list and find their opposites in the blue box.

| expensive thin quick good easy small empty dry little angry early |

bad cheap

friendly late

full slow

wet big

difficult

Look at the picture

Do you know each person? What’s her/his name and what’s her/his job?

For example: Mr Michael Benson is the man a grey shirt. He handles the orders…

Describe a photo

Look at the photo. What can you see? Use the vocabulary beside the photo.

computer

keyboard

flatbed scanner

image

layout

reflective original

desk

Ethan Bootman explains Liza that different computer programs use various ways to calculate their own information. It is very important to know which programs work with what kind of display format. Vector graphics usually need less memory than pixel graphics. Normally you can’t handle continuous-tone images with a vector graphic program.

Now read the text below.

Original

100%

| Pixel graphics |

200%

| Vector graphics |

| Vector graphics |

| Pixel graphics |

More about this topic

Questions about the text

1. Which two pieces of information do you need to describe a pixel?

2. How can you avoid that pixel graphics look jagged?

| Adobe Illustrator QuarkXPress Adobe Photoshop InDesign CorelDraw |

1. Which of the programs on the right are pixel and which are vector programs?

2. Both circles are vector graphics. Which one uses more memory and why?

3. This photo should be expended. What format do you need?

4. Is it possible to display vector graphics in a pixel graphic program?

5. Is it possible to display pixel graphics in a vector graphic program?

6. What could happen with the quality if you have reduced a pixel image? Is the quality the same or is it worse?

1. 2.

All about words

Find the opposites

Find the matching words

| enlarge reduction scarcity brief decrease various dependent equal increase jagged smooth expansion reduce independent profit detailed |

Liza gets a CD from a customer while Barbara is in the recreation room drinking another cup of coffee. Liza loads the CD into the computer and finds a file named “brochure.pdf”. Xpress is unable to open this file format. She asks Ethan how to open it and he explains to her the different kinds of data formats. He also gives her some information about this topic.

More about this topic

Link the matching boxes

Read the boxes placed round Liza. Link the name of the data formats with the matching explanation in the blue box and then connect them with the yellow boxes which describe how these formats are mostly used.

| It is used… |

| This format… |

| GIF |

| This data format is based on PostScript code. It can be imported into other programs. The embedded information can’t be changed. Graphics in this format can be pixel as well as vector orientated. |

| Every computer can read this format. It uses indexed colours (up to 256), therefore the file size of pictures is strongly reduced. It’s used for logos, graphics and images. The content of this format can be transparent, animated or interlaced. |

| This format is used for pixel graphics only. It can be handled on almost every platform. The information of a picture is stored in “tags”. This format needs a large storage space. Therefore, the format offers a lossless compression (LZW). |

| Based on PostScript, this format contains images, graphics, fonts and other information. The file size is very small and the quality of the data can be adjusted at the output. Additionally, the user can display the file and make changes in the document. |

| This is not only a format but also a way to compress. The advantage of this format is the small size of the file because data can be compressed high. There are several compression steps – the higher the compression rate, the greater the loss of quality |

| JPEG Joint Photographic Experts Group |

| PDFPortable Document Format |

| TIFFTagged Image File Format |

| GIFGraphics Interchange Format |

| EPSEncapsulated PostScript |

| It’s used for vector information as well as for image data that is not supposed to be manipulated by the user. You can store isolated figures, characteristic print lines and fonts with this format. |

| This format is, because of its small size, mainly used in the Internet or in quantity-optimized pre-press workflows (newspapers). The distiller of Acrobat uses this format for compressing pictures in a PDF-File. |

| The function of this format is to display images on the Internet. The size is small and there are three variants to display them. HTML uses this format to display pictures and graphics.. |

| It is used in several digital workflows and it’s established as a standard for information interchange of complex data. It hasn’t existed as long as the other formats. |

| Colour and gray level-pictures in every size and resolution can be saved in this format. It is the most commonly used data format to place pictures into dtp-programs. |

More about this topic

Complete the illustration

Fill in the words. You can find the matching

| Scanner Colour printer Proof printer Word processing Camera Imagesetter Picture database Printing presses |

“This is a photo of my favourite soccer-team. Can you digitalize it for me? I would like to publish it on the Internet”, Dylan Oliver said to Liza. She promised him to do that, but she has never scanned photos before. Anita is now explaining to her haw a scanner works and how to use it.

How a flatbed scanner works

A scanner server as the eyes of a personal computer. It contains thousands of cells that work like the eye of a bee: It can see photographs, art work, and read hard copy text (with the appropriate software). Scanners look and operate much like copiers and share much of the same technology.

But the outward simplicity is deceptive. Inside the scanner is a linear array called a charge coupled device (CCD), which is composed of about 2 600 photosensitive cells or elements. In most desktop scanners the CCD is only about an inch square and is fixed in place.

A light bar moves across the object being scanned (the target), and the light is reflected to the CCD by a system of mirrors. Each cell produces an electrical signal proportional to the strength of the reflected light that hits it. The signal which represents one pixel in the original images is converted into a binary number and sent to the computer. Darker portions of the target reflect less light and are given lower numbers.

Most desktop scanners today have CCDs that can differentiate 256 shades of gray or levels of brightness. That is about the same brightness range as a black and white photograph and roughly twice what the human eye can distinguish.

How does a scanner capture colour with the same CCD?

The answer: by creating three separate versions of the image, one for each of the three priLiza colours of light reflected by the target.

There are two different methods to create this. The three pass method and the single pass method.

Based on: http://www.k12.nf.ca/belanger/howto/scanner6.htm

Single pass method:

The light ray is projected onto three CCDs. Each of them has a filter. Every line of the picture is scanned just one time. The recording of the colour components is happening simultaneousely.

Three pass method:

The light ray is guided through a rotating filter wheel. The light signals are guided one after another for blue, red and green onto the CCD. Every line of the picture is scanned three times. There exists just one CCD.

More about this topic

Questions about the text

1.What is a CCD? Explain in your own words.

Draw a diagram

Draw a diagram of the single pass method and the three pass method for your documents. Use your own words to describe these two methods.

Barbara needs Liza’s help: “Can you help me? Please open these files from our customer. Check if they are all right.” Liza tries to open them, but it’s not possible. Barbara helps Liza. “These files are produced on a Mac and they a named wrong. You can’t open them on a PC. But there are some more problems concerning data exchange between Mac and PC.”

Introduction

If you plan to regularly exchange DTP files between Macintosh and Windows, you obviously have to choose a program existing on both platforms, like the following programs: Quark Xpress, InDesign and PageMaker. Further to that, the three main points you should consider are:

· Fonts

· Graphics

· Filenames

Fonts

The fonts used on the source computer must exist on the target computer. If it is not the case, there are some font transfer solutions, but they can’t save all problems, mainly reflow problems (for an example, a main title on one line on the Mac reflows to two lines on the PC).

More, there is a strong consens amongst DTP professionals to only use Postscript fonts (Type 1) and not True Type. This could change with the recent agreement between Adobe and Microsoft about the new Open Type standard. Anyway, there could be a pretty long transition period, as many users will want to protect their huge investments in fonts.

Problems often occur when a Type 1 font bears the same name as a True Type font. More, some True Type fonts are not coded with a great care.

For the time being, the real solution is to define a set of Type 1 fonts existing on both platforms, preferably from the same vendor, and to stick with it. Some vendors propose fonts CD on Mac and PC. You should consider these offers.

Graphics

The main problems with included graphics come from two formats: Pict files from the Macintosh and WMF (Windows metafiles) from the PC (sometimes also from BMP files). All DTP professionals agree using only Tiff files (bitmap graphics) or EPS files (vector graphics). You will also avoid problems using uncompressed files.

Filenames

When you create DTP files on the Macintosh, you should be aware that if your files are to be opened under Windows, there are still more “illegal” characters on the PC side than on the Macintosh (which only prohibits ‘:’). Think it twice before using bullets, slashes, ‘<’, ‘>’, ‘©’, etc.

In the other direction, the file length is still limited to 31 characters. More, if the files are to be put on a CD burnt in the ISO 9660 format, the Macintosh will still only see the short filenames and not the long ones.

MS-Publisher

What we said above holds generally true and applies to all professional packages (InDesign, Xpress, PageMaker). In this context, we should also mention MS-Publisher. While Publisher presents itself as a “light” layout program and only exists on the PC (which tells a lot about the orientation of its publisher), it often happens that professional DTPists get MS-Publisher files from customers.

The workflow to print to a Postscript printer and going the PDF route with Distiller also applies to MS-Publisher. This is often the only good solution if the customer really did a lot of work and doesn’t want to pay the price to redot everything.

PageMaker 7 for Windows includes a program to convert the MS-Publisher files. The tool doesn’t exist in the Macintosh package. The result can then be opened in PM7 or in InDesign. There is often a lot work to do to recreate the pages, but sometimes it is a good working solution.

Source: www.macdisk.com/dtpen.php3

More about this topic

All about words

Explain in your own words

computer platform (line 5) DTP professionals (line 41)

target computer (line 15) illegal characters (line 49)

huge investments (line 26) redot (line 72)

not coded with a great care (line 30) recreate pages (line 78)

Talk about it

Can you name any other problems that might occur while transferring data between Mac and PC? Have you experienced similar problems in your company? Name an example.

Liza wants to know more about the different

kinds of workflows. Anita explains Liza how the

customers’ data pass through the company.

Looking at the diagram

Which workflow is the newest, which one is the cheapest, which one is the simplest and which one has the shortest run length of order? Look at the diagram and talk about it.

Source: Kipphan, Handbook of Print Media, Springer 2001, ISBN 3-540-67326-1

Unit 1: P r e P r e s s

| to introduce media-operator-trinee pre-press data-transfer gravure gravure-factory printing method department administration to handle take a seat to increase Team of MasterPrint responsible weakness bug to take over printing engineer to prepare competition trade limited leisure time troubleshooter customer supplier solution trying balance costing utilized stop to make publicity order structure print run die-cutter adhesive binding bindery to solve to design to decide keyboard flatbed scanner image layout reflective original desk various to calculate display format memory continuous-tone grid square particular colour value enlarged resolution jagged smooth characteristic therefore dependent independent expansion contours to affect output device suitable exchange formats scaleable comparison brief detailed Data formats recreation room unable purpose to store to support to require quality loss to compress common lossy master copy application to edit word processing storage space embedded font file size to adjust additionally gray level-pictures quantity-optimized indexed colours content lossless isolated figure characteristic print line the higher established interchange galley proof to attach coloured proof printer Translation PDF-article final remark unaware consequences to attend progressive to publish undertaking legible to repeat means of communication precisely to aim portrayal equal typeface Art work appropriate deceptive linear array light bar target to differentiate brightness levels to capture light ray simultaneousely electrical charge drum scanner Concerning obvious further to consider source to reflow among recent agreement transition huge to bear coded preferably to stick to propose to avoid to be aware to prohibit to apply to mention to recreate similar Workflow diagram print specifications master to ink print sheet | вводить верстальщик допечатная подготовка передача данных гравюра фабрика глубокой печати печатный метод отдел администрация манипулировать сесть увеличиваться наборный цех ответственный слабость ошибка принимать технолог подготовить соревнование торговля ограниченный досуг аварийный монтер заказчик поставщик решение попытка баланс ценный используемый остановка делать рекламу структура тираж штанцевальный пресс клеевое скрепление переплетно-брошюровочное производство решать проектировать решить клавиатура планшетный сканер изображение расположение оригинал монтажный стол различный подсчитывать отображение данных на дисплее память плашка сетка квадратный подробный цветовое значение увеличенный разрешение зубчатый гладкий характеристика поэтому зависимый независимый расширение контуры воздействовать выводное устройство подходящий заменяемый форматы масштабируемый сравнение резюме детализированный форматы данных комната отдыха неспособный цель запасать поддерживать требовать потеря качества сжимать общий расход офсетная форма приложение редактировать текстовая обработка складские площади закладной шрифт файловый размер настраивать дополнительно черно-белые изображения оптимальное количество индексные цвета содержание минимальные расходы изолированная фигура характеристическая печатная линия выше установленный чередование корректура в гранках прикреплять закрашенный непроницаемый принтер ретрансляция PDF –издания конечное замечание не сознавая последствия следить прогрессивный издавать совершение четкий повторить средства связи точно нацеливаться изображение равный гарнитура художественная работа соответствующий вводящий в заблуждение аналоговая матрица легкий брусок цель дифференцировать яркостные уровни захватывать лазерный луч симуляция электрический заряд барабанный сканер относительно очевидно далее рассматривать источник обратное движение среди современный соглашение перемещение огромный поддерживать закодированный предпочтительно застрять предлагать избегать знать запрещать наносить упоминать обновляться подобный схема технологического процесса спецификация печати мастер красить копировальный материал |

Unit 2. Press

More about this topic

Different printing methods

Liza passes through the press-department. She learns to distinguish the different printing methods, how to deal with paper and she gets know the workflow in this department. Dylan gives Liza this work-sheet to control her success:

| Link the main printing technologies with the matching text and methods |

| Main printing technologies Letterpress Gravure printing Lithography Screen printing |

| Characteristics of the printing form The printing form I a screen with a stencil; images areas are in the screen permeable for the colour. Image areas and non-image areas are at the same level. Image areas are on a higher level than non-image areas. Image areas are on a lower level than non-image areas. |

| The matching printing methods -flexography · Continuous stationery printing (partly) · Stone printing · Offset · Tin printing · Phototype -continuous stationery printing(partly) -manuell techniques: copperplate, dry point engraving -gravure printing · Screen printing |

Describe the photo

Look at the photo. What can you see? Use the vocabulary below.

printing machine

sheet feeding

sheet piles

trolley

sheets

pallet

| Sheet-fed-offset flexography Rotary Gravure offset printing Others |

More about this topic

Questions about the text

1.Which technology plays the second largest part in printing?

2.What was flexography used for?

Your notebook and add

The following words to

the picture:

-plate cylinder

-printing plate

-impression cylinder

-doctor blade

-ink trough

-anilox roller

-printing material

Source: Kipphan, Handbook of Print Media, Springer 2001, ISBN 3-540-67326-1

Flexography

Flexography is the only printing technology which can print on very thin, flexible, and solid films. Nearly all papers, thick cardboard and rough-surfaced packaging materials can be used. The print quality which is possible in flexography is lower compared to offset printing. The resolution is usually also lower with flexography than with offset printing.

However, modern printing plates have improved printing quality very much. Especially those plates that are produced with computer-to-plate imaging systems. Printwork with a screen frequency of 60 lines/cm (even of up to 120 lines/cm) can be produced. The use of new types of printing plates with adapted inks and technical printing press developments have extremely improved the printing quality offered by flexography.

Identification signs

-dot image

-big spread

-products are often flexible

-rough screens

Advantages

-fast printing technology (up to 400 m/sec)

-fast drying printing ink

-inline-finishing

-quick preparation

Disadvantages

-low opaqueness of the printing ink

-register differences

-the repeat length must be coordinated with the tooted gearing

Based on: Kipphan, Handbook of Print Media, Springer 2001, ISBN 3-540-67326-1

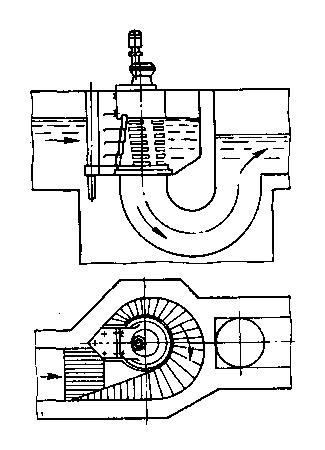

Copy this diagram into your notebook and add the following words to the picture:

Copy this diagram into your notebook and add the following words to the picture:

-inking unit -damping unit -blanket cylinder -printing material -impression cylinder -plate cylinder -printing plate -damping solution

Source: Kipphan, Handbook of Print Media, Springer 2001, ISBN 3-540-67326-1

Offset

Offset printing is an indirect lithographic printing technology. Offset printing has spread since about 1970. Offset replaced the litterpress printing technology which prevailed until that time. The offset printing technology is now the major printing technology.

Sheet-fed offset printing

Sheet-fed offset printing has economic and qualitative advantages over other printing technologies. Fundamental attributes of sheet-fed offset are flexible production options and the relatively economical production of printed products of a very high quality for a wide range of print volumes. In sheet-fed offset printing, printing materials of different sheet sizes and grammages are processed. Paper-vendors produce a great variety of standard material.

Identification sing

-types and lines have perfect edge definition

-fine screens

-no register differences

-the most usual printing material is paper in all variations

Advantages

-materials with different sheet sizes and grammages can be processed

-nearly all finishing operations are possible

-the quality is very high

Disadvantages

-complicated method =causes misprints

-sheet size just as big as machine size

-expensive printing machines

Based on: Kipphan, Handbook of Print Media, Springer 2001, ISBN 3-540-67326-1

Copy this diagram into

Your notebook and add

The following words to

the picture:

-doctor blade

-ink trough

-impression cylinder

-engraved cylinder

-printing material

Source: Kipphan, Handbook of Print Media, Springer 2001, ISBN 3-540-67326-1

Gravure printing

Gravure printing is a very good illustration printing technology, which ables to print in a very high image quality. Variable-depth and electronically engraved gravure printing cylinders are used, so that the cells take up different amounts of ink. As a consequence, different layer thicknesses are transferred to the paper.

The result looks nearly like the original (for example a photographic picture).

Typical gravure printed products are large print run, high-quality printed products such as:

-magazines, catalogs,

-plastic films,

-transparent films,

-stamps and

-bank notes.

Identification signs

-jagged edges at types and lines

-very good image reproduction

-often printed on absorbent paper

-used for products with are large print run

Advantages

-very fast printing method

-inline-finishing

-very good illustration printing

-easy printing method

Disadvantages

-complicated and expensive printing plate production

-profitable just with a very large print run

-the ink contains a very high portion solvent

Based on: Kipphan, Handbook of Print Media, Springer 2001, ISBN 3-540-67326-1

Screen Printing

Screen printing is one of the most versatile processes for transferring ink and coatings. Its application ranges from craftswork applications to the large-scale industrial sector. Extremely small components in sensor production are also produced as 3 m x 6 m formats in flat glass finishing. It’s possible to produce single-items or products with a large print run. Printing can be done on paper, textiles, ceramics and plastic on endless webs and single sheets. It also can be done on objects of the most varying nature and form, such as glasses and control panels. The range of inks is varied. Very often special inks are involved that are adapted to the relevant applications.

The machinery and systems for screen printing range from the simplest of devices to large-scale industrial production plants.

Identification signs

-a thick, sensible ink film

-for products have various forms

-structure of the screen can be seen in the ink

Advantages

-nearly all products of every can be processed

-products with large format can be produced cheap

Disadvantages

-the drying of the ink takes a long time

-the printing capacity is not as fast as with other printing methods

Based on: Kipphan, Handbook of Print Media, Springer 2001, ISBN 3-540-67326-1

More about this topic

Teamwork

Find some printed products at home and bring them along. Use a magnifying glass to read the identification signs: What printing methods were used?

Questions about the text

1.For what reason does Mr Jason want to buy a digital printing machine?

2.Is it difficult to integrate a digital printing machine into the workflow of MasterPrint?

3.Why is there a need to employ another printer?

4.What costs do arise when you buy a new machine? Can you name any other kinds of cost?

Explain in your own words

a profitable machine

integrate

operate

data handling

Liza is having a basic training in offset printing. She helps Samuel to print at the SM74. A monochrome printing job is too dark in all colour gradations. Samuel tells Liza that the problem is caused by filling in of halftones. But there are some more mistakes that can occur. Samuel talks about types of misprint that can occur while printing with an offset printing machine.

More about this topic

Correct bad

Print print

| This type of misprint can often be seen in four-colour works or solid areas. It is possible to prevent this error when the printing image is arranged differently. |

| This problem can be prevented by changing the sequence of the printing units or by using another printing material with a better absorption ability. The problem will increase when printing with more than one colour. |

| The cause is often too much inking, too less dampening, too high pressure from blanket to plate cylinder or the blanket is not tight enough. |

| Use a magnifier to proof this misprint. Many factors can be responsible. The error is often caused by the printing material. Dot gain is the consequence. |

| -This error in lateral direction seldom occurs alone. Check the printing material and the blanket. -This error in print direction can occur when the rolling of the plate and the blanket cylinder is not correct. |

Source: Kipphan, Handbook of Print Media, Springer 2001, ISBN 3-540-67326-1

Mr Jason is reading an article from MAN Roland “expressis verbis”. The article is about the future, the advantages and the disadvantages of digital printing.

More about this topic

Fill in the missing words

Copy the text into your notebook and fill

in the missing words from the yellow box.

The printed page is created by converting data into ____ which then erases charges on a charged, photosensitive rotating drum, thus reproducing information as an electrostatic pattern on the drum. The light source is a laser beam.

In the next step of the process, the drum comes in contact with a charged colour powder (____) and a pattern develops when the powder is attracted to the drum wherever a ______ remains. In the following step the developed pattern is transferred to ______ with the help of a strong electrostatic field. The drum must then be discharged, cleaned and recharged before it is ready for the next ____. At the same time the paper passes through a ____ where the toner is bonded to the paper fibers with the help of pressure and heat.

Liza looks at a printing plate through a magnifier. She notices that the screens of the products are different from each other. Kevin tells her about the AM and FM screening methods.

Screening methods

You can simulate continuous tones with screening in a number of ways.

Amplitude Modulation. In so-called amplitude-modulated screening (autotypical screening, periodic screening), the individual dots are spaced the same distance apart, but have different diameters (or different areas, depending on the dot shape). This halftone process, along with its distinct susceptibility to moire, is the more conventional one.

Frequency Modulation. In the case of frequency-modulated screening, the individual dots have the same diameter but are different distances apart (non-periodic screening). When using the frequency modulation screening process to convert continuous tones of the original into a quantity of dots in a so-called screen cell, the dot spacing must be specified for a known dot size. This can be done according to various algorithms. Usually the distances for a certain tone value differ from individual dot to individual dot (which would lead to susceptibility to moire patterns), but are distributed randomly. For this reason, frequency-modulated screening is also referred to as random or stochastic screening.

The graphic illustrates both screening processes, amplitude-modulated and frequency-modulated. The single-colour image shows that, when using identical dots of the smallest possible size, FM screening produces better reproduction of detail in printing than AM screening; it must also be possible to repeatedly reproduce each of the small dots in print. At multi-colour works one can clearly see that the FM screening produces a higher resolution and that its stochastic, random screening prevents rosettes.

Hybrid Screening. There are also hybrid techniques for screening continuous-tone originals: both AM and FM screening are used, depending on the image. A possible algorithm is based on the approach of using FM screening for very light and very dark tones and AM screening for the remaining tone value range.

Based on: Kipphan, Handbook of Print Media, Springer 2001, ISBN 3-540-67326-1

More about this topic

Unit 2: P r e s s

| The press department numering box conventional monochrome printworks multicolor printing unit imagesetter print run gang-stitcher knife trimmer cutting machine Printing methods to pass through distinquish to deal with letterpress gravure printing screen printing printing form image areas screen stencil permeable flexography continuous sttionery printing stone printing offset tin printing phototype cooperplate dry point engraving Process technologies sheet-fed offset rotary offset entire former identification sign Printing machine sheet feeding sheet piles trolley sheet pallet Flexography plate cylinder printing plate impression cylinder doctor blade ink through anilox roller printing material solid film cardboard rough surface screen frequency adapted ink dot fringe big spread inline-finishing preparation opaqueness register differences repeat length toothed gearing Offset inking unit damping unit blanket cylinder damping solution to spread to replace to prevail major fundamental attribute wide range of print volumes grammages vendors misprint Gravure printing engraved cylinder illustration printing amount layer absorbent paper solvent Screen Printing rubber doctor blade frame versatile coating craftswork web control panel sensible printing capacity Magnifying glas Digital printing profitable purchase profitability to integrate to discuss precondition print image print image carrier to print on to arise Printing problems in offset printing colour gradations filling-in to occur disappearance slurring slippage ghosting doubling re-transfered circumference-direction Lateral slurring mottling spotty and cloudy ink absorption overlap direction of print inking roller due to ink splitting revolution solid area to prevent sequence tight rolling The market of digital printing reorientation amazement short print run distribution printing on demand invoices confirmations in-house previously lack considerable scope barriers in order to advertisers database inadequate knowledge willingness maintenance legal restriction to impose legislation attitude restrictive to fail return on investment bulk instead to persuade to claim to take account responce rate persuasive tailored requirement focus rotogravure The principle of electrophotography sheet pass fuser unit charge corona charged toner to erase pattern to develop to attract discharged to bond Screening methods screen amplitude modulation apart diameter distinct susceptibility frequency modulation screen cell dot spacing to differ random reffered to repeatedly approach dot contact | нумератор условный монохромное изображение полноцветное изображение печатная секция выводное устройство тираж брошюровальная машина ножевой триммер резательная машина прогон листа различать иметь дело высокая печать глубокая печать трафаретная печать печатная форма печатные элементы печатная форма трафаретной печати трафарет проницаемый флексография рулонная печать литография офсетная печать печать на жести фототипия медная пластина гравирование «сухая игла» технологические процессы листовой офсет рулонный офсет целиком формный цилиндр идентификационный знак печатная машина листоподача стопа тележка лист палета/поддон флексография формный цилиндр печатная форма печатный цилиндр ракель красочный ящик анилоксовый вал запечатанный материал сплошная пленка картон шероховатая поверхность линиатура смесевая краска растискивание крупный растр работа в линию быстрая приладка непрозрачность расхождение приводки длина формного цилиндра зубчатый механизм офсет красочный аппарат увлажняющий аппарат офсетный цилиндр увлажняющий раствор растрировать заменить превалировать главный базовый атрибут диапозон печатной продукции плотность бумаги поставщики опечатка глубокая печать гравировальный цилиндр иллюстрационная печать количество слой адсорбция бумаги растворитель трафаретная печать резиновый ракель рама многосторонний лакирование ручная работа лента панель управления чувствительный производительность увеличительное стекло цифровая печать прибыльный прибыль выгода внедрить обсуждать предварительный запечатанное изображение перенос изображения запечатывать появляться проблемы офсетной печати тоновая градация тенение происходить исчезать дробление проскальзывание шаблонирование дублирование перенос направление окружности осевое дробление микронеоднородность пятнистость и облачность адсорбция краски наладка направление печати красочный вал обусловленный раскат краски переворот плашка предупреждать порядок стяжка вращение рынок цифровой печати переориентация изумление короткий тираж распределение оперативная печать формуляр подтверждение внутренний раньше нехватка важный сфера барьеры с целью реклама база данных неподходящий знания готовность обслуживание ограничение позиция законодательство отношение ограничительный провалить прибыль крупный заказ вместо убеждать заявлять учесть рентабельность убедительный приспособленный требования фокус глубокая офсетная печать принципы электрографии листопрогон сушка коронный разряд заряженный тонер снятие заряда образец проявлять притягивать разряжать закреплять принципы трафаретной печати трафарет амплитудная модуляция друг от друга диаметр особый восприимчивость частотная модуляция растровая ячейка заполнение различаться случайный относиться к чему-либо неоднократный приближаться прикосновение |

Unit 3: Finishing

Liza has moved on to the finishing department. Luke gives her some basic information about paper. He tells her that it is very important to know the grain direction of the paper. For each finishing option you have to pay attention to the correct grain direction. Otherwise it can cause problems with the finishing process of the product.

Grain direction in paper

Paper, like wood, has a grain. The direction in which the web moves through the paper machine is called the grain. The direction across the web is called against or cross the grain. With the grain there is greater strength. Against the grain there is greater expansion and contraction. This expansion makes it less stable. If a book is printed with the paper grain parallel to the spine it will open more easily and lay flat. Adhesive binding paper with the wrong grain direction can produce very bad results. Here are some simple tests to recognice the paper grain direction:

Folding test:

Folding test:

When folding a small sheet of paper you will

notice that it folds more easily when the fold is parallel to the grain. If folded against the grain, the small fiber particles break and it is not possible to make a good fold.

Fingernail test:

Slide down with your fingernails the vertical

and horizontal edges of the paper sheet. With

the grain there is no change. Against the grain

the paper edges will become wavy.

Bending test:

Thicker paper are best tested by bending them

in both directions. One direction offers more

resistance than the other. Parallel to the grain

direction the resistance is less than against the

grain.

Tearing test:

A sheet is torn in horizontal and vertical

directions. The form of the tear will be straight when parallel to the grain. The form of the tear will be jagged cross to the grain.

Moisture test:

Moisture test:

Moisture is applied to one side of a sheet. The sheet immediately starts to curl in one

direction. The expansion is on the cross grain edge. The curl shows the paper grain direction.

| Paper grain should be parallel with the binding edge! |

Based on: Kater-Crafts Bookbinders, California; www.katercrafts.com

More about this topic

Questions about the text

1.Describe the process the grain direction results from

2.What grain direction makes the paper more stable?

3.What test is used for testing thicker paper?

4.What happens with the fiber particles when you fold a paper against the grain?

5.Does paper expand in the grain direction or cross grain?

6.What direction must the fibers lie in that the tear will have a straight form?

For experts: reflect on the text

1.What is the result when you bind a book with adhesive binding and you use the wrong grain direction?

Liza tries to find out the grain direction of different paper sheets. Luke tells her to write down her results. But that’s the next problem:

How do you write down the grain direction in connection with the paper format?!

The characteristics of

The grain direction

-underline one number of the format (stretch direction) 61 x 86

-write the machine direction (md) of the paper machine after one number of the

format 61 x 86 md

-short grain (sg) or long grain (lg) 61 x 86 sg

-draw an arrow under one number of the format (grain direction) 61 x 86

Liza wants to know if there are some more things which must be checked before you finish the product. She asks Luke about this topic.

More about this topic

Print finishing products

Describe a photo

Look at the photo. What can you see? Use the vocabulary beside the photo.

cutting machine

cutting material

measure of the format size

program

cutting waste

More about this topic

Buckle Folding

A buckle folding station consists of three folding rollers and a buckle plate. The first two rollers are arranged vertically above one another. Their job is to carry the incoming sheet into the buckle plate until it reaches an adjustable feed guide stop.

The sheet is delivered into the buckle plate at a speed determined by the characteristics of the paper. As the lead edge of the sheet strikes the feed guide stop, the sheet continues to be led into the buckle plate, creating a buckle in the space between the three rollers.

As the excess paper drives downwards it is grabbed by the contra-rotating rollers and the fold is formed as the sheet passes through them.

Unlike knife folding, buckle folding is not restricted to any cyclical movement, which makes it ideal for high-speed folding. Each folding station can fit up to six buckle plates, arranged alternately above and below each other, allowing for a large number of fold variations.

Based on: Finishing experts group, Inc

Copy this diagram into your notebook and add the words below to it:

- Folding rollers

- Buckle plate

- Feed guide stop

- Space where the buckle is created

Knife Folding

Knife folding uses a vertically moving knife and two rollers rotating in opposite directions. The sheet is carried from the feed to the folding station until it has contact with the sheet stop. At this point, the knife moves vertically, plunging the sheet between the folding rollers. The rollers have been set to the thickness the sheet going through them. As

sheet passes through the rollers, it is pinched and the fold is formed.

Only one folding knife is to be found in any one folding station. For every following fold, it is necessary to have a further knife folding station at right angles to the preceding one. Binders specializing in folding large sheets usually use knife folders.

Based on: Finishing experts group, Inc

Copy this diagram into your notebook and add the words to it:

- Folding rollers

- Knife

- Sheet stop

More about this topic

What is folding?

Folding involves the use of a tool or mechanical _________ to produce a sharply defined ________. The pressure required for folding may be applied manually with the use of a _______.

In mechanical folding the sheet is doubled between ________ while pressure appropriate to the _________ of the paper is exerted. The end result is a sharp fold that virtually eliminates the paper’s ________ to revert to its original _______.

Liza has noticed that some folds are always the same. Is this a coincidence or a basic rule? To find out more, she looks it up in a book. Here she finds a table with the basic types of folding and their folding layouts.

Types of foldings

Foldings can be classified as crossfolds and parallel folds. A sheet that is folded only once is a two-panel brochure. In case that several folds are necessary, various sequences of folding are possible. A paper with crossfolds has a second fold at right angles to the first fold. In comparison, a paper with parallel folds has always a fold parallel to the preceding one. Both types of foldings are usually applied to the production of brochures.

((__lxGc__=window.__lxGc__||{'s':{},'b':0})['s']['_228268']=__lxGc__['s']['_228268']||{'b':{}})['b']['_697691']={'i':__lxGc__.b++};

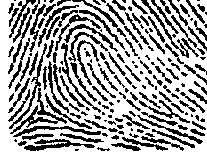

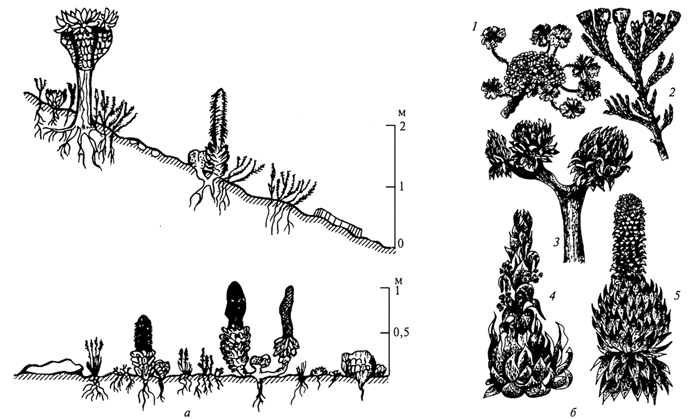

Папиллярные узоры пальцев рук - маркер спортивных способностей: дерматоглифические признаки формируются на 3-5 месяце беременности, не изменяются в течение жизни...

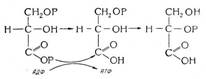

Биохимия спиртового брожения: Основу технологии получения пива составляет спиртовое брожение, - при котором сахар превращается...

Состав сооружений: решетки и песколовки: Решетки – это первое устройство в схеме очистных сооружений. Они представляют...

Адаптации растений и животных к жизни в горах: Большое значение для жизни организмов в горах имеют степень расчленения, крутизна и экспозиционные различия склонов...

© cyberpedia.su 2017-2024 - Не является автором материалов. Исключительное право сохранено за автором текста.

Если вы не хотите, чтобы данный материал был у нас на сайте, перейдите по ссылке: Нарушение авторских прав. Мы поможем в написании вашей работы!