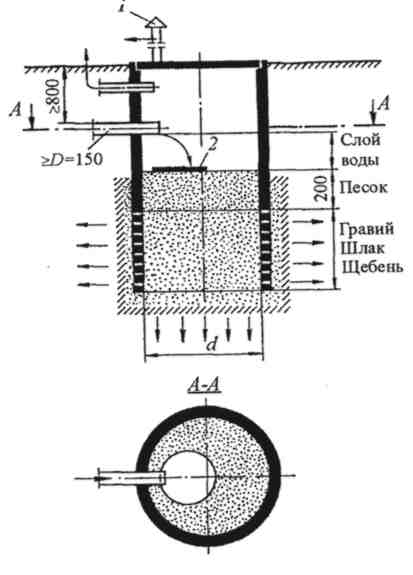

Индивидуальные очистные сооружения: К классу индивидуальных очистных сооружений относят сооружения, пропускная способность которых...

Кормораздатчик мобильный электрифицированный: схема и процесс работы устройства...

Индивидуальные очистные сооружения: К классу индивидуальных очистных сооружений относят сооружения, пропускная способность которых...

Кормораздатчик мобильный электрифицированный: схема и процесс работы устройства...

Топ:

Проблема типологии научных революций: Глобальные научные революции и типы научной рациональности...

Генеалогическое древо Султанов Османской империи: Османские правители, вначале, будучи еще бейлербеями Анатолии, женились на дочерях византийских императоров...

Интересное:

Наиболее распространенные виды рака: Раковая опухоль — это самостоятельное новообразование, которое может возникнуть и от повышенного давления...

Берегоукрепление оползневых склонов: На прибрежных склонах основной причиной развития оползневых процессов является подмыв водами рек естественных склонов...

Подходы к решению темы фильма: Существует три основных типа исторического фильма, имеющих между собой много общего...

Дисциплины:

|

из

5.00

|

Заказать работу |

|

|

|

|

1.Describe the process of knife and buckle folding in your own words.

2.What might be a disadvantage of knife folding?

3.Can buckle folding be used for every material?

4.Which folding machine can produce fold variations?

5.How many buckle plates can be arranged in a buckle folding machine?

| pressure bone folder rollers thickness natural tendency fold form |

Copy this text into your notebook and fill in the

missing words from the blue box.

What is folding?

Folding involves the use of a tool or mechanical _________ to produce a sharply defined ________. The pressure required for folding may be applied manually with the use of a _______.

In mechanical folding the sheet is doubled between ________ while pressure appropriate to the _________ of the paper is exerted. The end result is a sharp fold that virtually eliminates the paper’s ________ to revert to its original _______.

Liza has noticed that some folds are always the same. Is this a coincidence or a basic rule? To find out more, she looks it up in a book. Here she finds a table with the basic types of folding and their folding layouts.

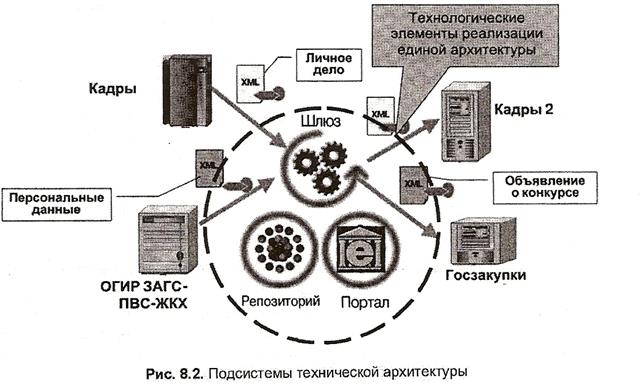

Types of foldings

Foldings can be classified as crossfolds and parallel folds. A sheet that is folded only once is a two-panel brochure. In case that several folds are necessary, various sequences of folding are possible. A paper with crossfolds has a second fold at right angles to the first fold. In comparison, a paper with parallel folds has always a fold parallel to the preceding one. Both types of foldings are usually applied to the production of brochures.

Crossfold

This folding sequence is usually applied to book printing, producing 4-, 8- or 16-panels. Here the complete width or length of a sheet is being folded. The number of the pages resulting from a

symmetrical folding sequence can be seen in the table on the right. The quantity of panels (and following from it the quantity of pages) can be calculated by raising the number 2 to the power of the number of folds. (Notice that 1 panel =2 pages!).

| Type of folding | power | panels | Pages |

| One fold | 21 | ||

| Two folds | 22 | ||

| Three folds | 23 | ||

| Four folds | 24 |

| Sequence of The folds: 1, 2, 3, 4 1 3 1 2 2 four page fold sixteen page right angle fold 1 3 1 4 22 2 eight page thirty two page right angle fold right angle fold |

Parallel fold

Parallel folding is mostly applied to job printing and to processing book printing sheets in two up production. The folds are parallel to each other. Different forms and variations are possible:

1.Parallel fold

The full length of the sheet is folded. The number of pages doubles constantly because of the symmetrical folding.

|

|

2.Zigzag fold or accordion fold

Part of the width of the sheet is being folded asymmetrically. The direction of folding is hereby constantly changing to the left and to the right. Accordingly, a zigzag with two folds has 6 pages and a zigzag with three folds has 8 pages.

3.Letterfold

Similar to the zigzag fold, a part of the width of the sheet is being folded asymmetrically. But: here the folding direction does not change. The pages are “rolled up” into each other. The quantity of pages is the same as with zigzag fold.

4.Gatefold

A paper with a simple gatefold has two parts of sheet folded to the centre. A paper with a double gatefold additionally is folded in the centre, parallel to the preceding folds. In order to avoid overlapping or buckling, the flaps should have a gap of about 1,5 mm to the centre fold.

5.Combination- and special folds

Brochures can have multitude of combinations of parallel- and crossfolds.

More about this topic

For experts: reflect on the text

1.What kind of fold follows after the first one when you make a crossfold?

2.How many folds has an eight page right angle fold?

3.What kinds of products do you know which re folded in letterfold?

4.How can the flaps of a gatefold be prevented from overlapping or buckling?

5.How many pages do you get from a zigzag

folded two times?

Type of folding

Based on: Kipphan, Handbook of Print Media, Springer 2001, ISBN 3-540-67326-1

Luke gives Liza a job: She has to fold a dummy for a product with 4 pages. She wants to place page one and page four on one printing plate and page two and three on an other plate. But Luke gives her a tip: “place all pages on one printing plate only. This plate must be twice as big, but it is more economical because you can save one printing plate.”

Methods of imposition

There are two standard methods of imposition: 1) sheetwise; 2) work-and-turn; 3)work-and-tumble; and 4) work- and-twist. The purpose of having different schemes is to obtain maximum economy in printing.

Sheetwise imposition, also known as “work-and-back”, “front-and-back”, or “print-and-back”, requires two image carriers per colour, one each for the front and back of the sheet. This method I used for printing jobs where the number of pages to be printed on each side of the sheet is large enough to utilize the full capacity of the press.

Work-and-turn imposition, also known as “ print-and-turn”, is used where it is practical to print both sides of the sheet from a single image carrier per colour. It is frequently used, and requires relatively large presses because the sheet will carry two complete units, each occupying one half of the sheet. The sheet is slit during backup or is cut apart after printing. Work-and-turn imposition cuts the number of sheets to be printed by 50%, but it generally requires larger and more expensive presses than sheetwise imposition.

Work-and-tumble imposition, also known as “print-and-tumble”, “work-and-roll”, or “work-and-flop”, is used less frequently than either of the two previous methods. It is selected when a work-and-turn form cannot be used, or when two sheetwise forms would have to be run on a sheet of difficult dimensions. This method needs only one image carrier for printing both sides of the sheet, and in this respect it is similar to work-and-turn.

|

|

Work-and-twist imposition, also known as “ work-and-twirl”, differs fundamentally from all three previous schemes. But nowadays this methods is not often in use.

Source: http://palimpsest.stanford.edu/don/dt/dt1816.html

More about this topic

|

|

|

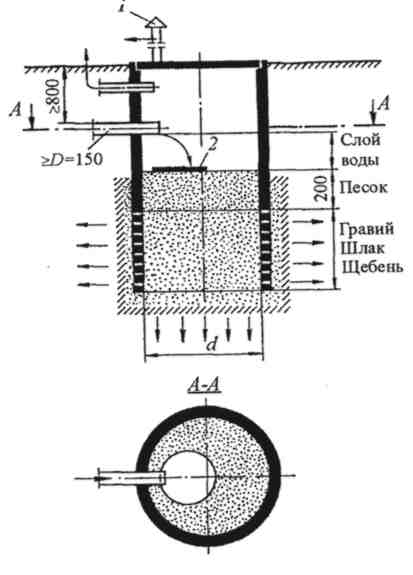

Архитектура электронного правительства: Единая архитектура – это методологический подход при создании системы управления государства, который строится...

Организация стока поверхностных вод: Наибольшее количество влаги на земном шаре испаряется с поверхности морей и океанов (88‰)...

История развития хранилищ для нефти: Первые склады нефти появились в XVII веке. Они представляли собой землянные ямы-амбара глубиной 4…5 м...

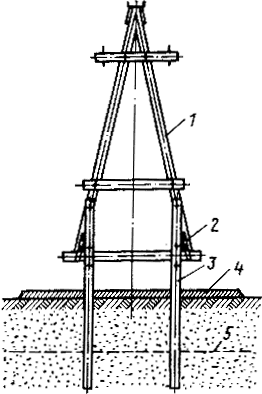

Особенности сооружения опор в сложных условиях: Сооружение ВЛ в районах с суровыми климатическими и тяжелыми геологическими условиями...

© cyberpedia.su 2017-2024 - Не является автором материалов. Исключительное право сохранено за автором текста.

Если вы не хотите, чтобы данный материал был у нас на сайте, перейдите по ссылке: Нарушение авторских прав. Мы поможем в написании вашей работы!