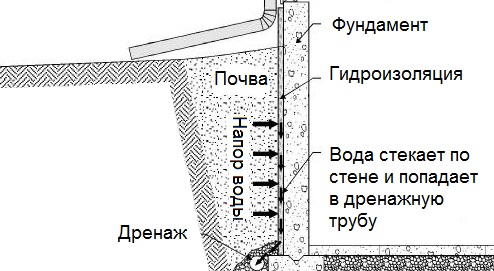

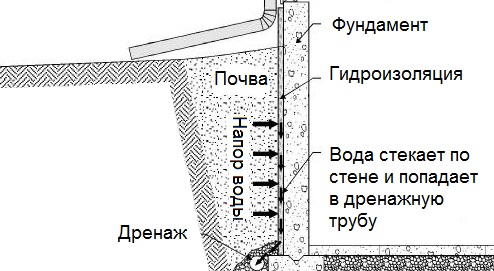

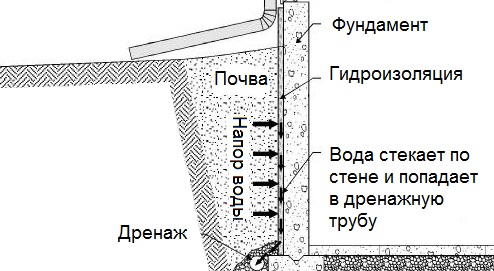

Общие условия выбора системы дренажа: Система дренажа выбирается в зависимости от характера защищаемого...

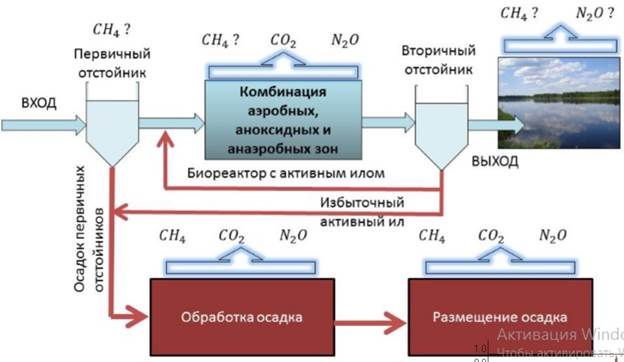

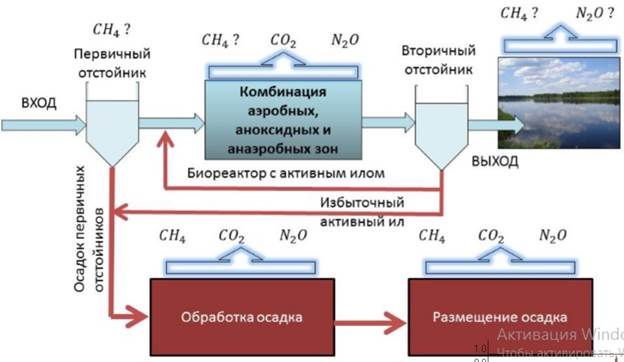

Эмиссия газов от очистных сооружений канализации: В последние годы внимание мирового сообщества сосредоточено на экологических проблемах...

Общие условия выбора системы дренажа: Система дренажа выбирается в зависимости от характера защищаемого...

Эмиссия газов от очистных сооружений канализации: В последние годы внимание мирового сообщества сосредоточено на экологических проблемах...

Топ:

Основы обеспечения единства измерений: Обеспечение единства измерений - деятельность метрологических служб, направленная на достижение...

Установка замедленного коксования: Чем выше температура и ниже давление, тем место разрыва углеродной цепи всё больше смещается к её концу и значительно возрастает...

Теоретическая значимость работы: Описание теоретической значимости (ценности) результатов исследования должно присутствовать во введении...

Интересное:

Как мы говорим и как мы слушаем: общение можно сравнить с огромным зонтиком, под которым скрыто все...

Наиболее распространенные виды рака: Раковая опухоль — это самостоятельное новообразование, которое может возникнуть и от повышенного давления...

Что нужно делать при лейкемии: Прежде всего, необходимо выяснить, не страдаете ли вы каким-либо душевным недугом...

Дисциплины:

|

из

5.00

|

Заказать работу |

|

|

|

|

More companies may collapse under the burden of high interest and exchange rates, the 15 per cent export tax and the GST.

The president of the Canadian Lumbermen's Association, Jim Hickey, foresees dark clouds looming in the future for the solid wood products industry. You could argue that his gloomy forecast is a little biased by the fact that his hardwood/plywood business is going under, weighted down by interest rates and the high value of the Canadian dollar. But Hickey is not the only pessimist, and it is clear that a number of factors threaten the survival of lumber producers in the 90s.

The recent closures of a number of businesses and the threat of an economic recession do not bode well for the industry. During the association's annual meeting, held February 14 to 16 in Montreal, the importance of staying efficient and competitive, and the need to exploit global markets were stressed. The goods and services tax (GST), the high exchange rate, high interest rates and the Memorandum of Understanding were the most commonly cited industry ills. Hickey said the failure of his company is symptomatic of what is happening to all the forest industries.

The grim forecasts began on Valentine's Day when Hickey told reporters

that profit margins are slim and companies have to produce at maximum capacity

and productivity to survive.

John Holland, Noranda Forest Sales, commented that the recent spate of sawmill closings is only a taste of what is to come in 1990. A lessening of demand for chips in Quebec could cause the disappearance of many mills, he explained.

Looking overseas for salvation is tempting, but not all mills have the flexibility to serve European markets, he said. However, he pointed out an opportunity for eastern Canadian producers is opening up in Europe. The Eastern bloc countries have always been a key supplier to continental Europe and North Africa but have recently reduced their export volumes to these areas by 15 to 20 per cent. This internal demand within the Eastern bloc has left somewhat of a vacuum in Western Europe which could be filled by Canadian products.

Financing for modifications is hard to come by, said Rolland, because no one in solid wood products is getting good returns. To serve European markets, mills have to expand their dry kiln capacity and change material handling systems to produce European sizes and packaging that will withstand overseas shipping.

On the domestic front, with the GST coming into effect in 1991 "there will be a dislocation of businesses and jobs," Hickey warned. He said he has already seen examples of companies moving across the border.

The tax will have to be financed by businesses at every step of the manufacturing process. For example, reload centres that purchase wood from mills will have to pay the tax on the material they process. This means a seven per cent tax on all their inventory, said Hickey. Wholesalers will also pay tax to the mills and only recoup it when they resell the wood. In the interim, wholesalers and reload centres will have to finance the tax.

|

|

While the GST is a burden in some ways, it could help the industry in

others. The pending introduction of the tax in 1991 is expected to boost housing starts this year. Despite high interest rates, potential home buyers are likely to build before the new tax comes into effect.

Painful slowdown

Further economic insight came in an indirect way from Coopers & Lybrand's Chief Economist, Maureen Farrow, during Thursday's luncheon. Farrow's speech was read by Hickey because bad weather kept her from reaching Montreal in time. She was cautiously optimistic about the next few years. "What I am predicting then is a coasting period, not a full-blown recession," she said. She expects a slowdown in the North American economy that could "be quite painful".

Farrow noted that interest rates, the exchange rate and U.S. housing starts are key variables for 1990. She predicts the Canadian dollar will trade at 82 to 83 cents U.S. for the next year, giving the Bank of Canada room to lower interest rates which recently hit a five-year high. As for housing starts, the probability of lower interest rates and lower mortgages points to better times ahead. For the long term, she suggested increased research and development in the fields of converting and value-added products.

She urged companies to make their move early and be proactive on both the global and environmental fronts. The industry needs to raise its profile on environmental matters because the public is watching it closely.

Another luncheon surprise was the winner of the 1990 Wood Award – jack McCracken. The CLA’s executive director looked fist shocked and then embarrassed as the litany of his achievements went on. When presenting the award, Hickey called him “a true leader of our industry”. In addition to guiding the CLA, McCracken is a director of the Canada Wood Council and Canadian Forest Industries Council, and president of the Canadian Lumber Standards Accreditation Board.

Caught unaware, McCracken’s thank you was brief. “I’ve enjoyed my service with you,” he said. McCracken retires at the end of 1990 and will be succeeded by Robert Rivard.

Not merely cosmetic

“It’s time for us to stop selling commodities and start selling a product,” Jacques Boudreau, Lulumco Inc., told the audience at Thursday morning’s panel discussion on Presentation of Product in the Marketplace. This sentiment was echoed by the other panelists, who encouraged mills to concentrate on both quality and packaging in order to enhance their image. “To speak of presentation is really to speak of quality,” said Pierre Bergeron of Scierie des Outardes.

A positive first impression goes а long way with our and customers.” Georgia-Pacific Corp’s Philip Rossmeisl agreed. “They are very pleased when a truck or rail car arrives in their yard in good condition, clearly identified and uniformly packaged. It makes the process of handling. Storing and re-shipping that much easier”.

Presenting the panel with a customer’s point of view, Rossmeisl suggested that standards be developed, such as green paint for the identification of green lumber and red paint for kiln-dried material. He added that timeliness and protection are important aspect of shipping.

Overseas shipping requires special consideration, said Bergeron, sales director. Overseas Markets, for Scierie des Outardes. Bundles may be handled eight or 10 times before reaching their final destination and they must be sturdy enough to stand up to this treatment. One panelist said forklifts sometimes drive on bundles stored under the deck. Bundles must also meet the specifications of the buyer’s country. Bergeron suggested exporters use bearers to facilitate handling, end painting and clear mill identification.

|

|

“Environmental issues have only started to influence customers’ attitudes,” Bergeron warned. Plastic wrapping for kiln-dried wood may fall out the horizon is bar coding, which Bergeron said may become necessary for international shipping.

Representing the European point of view, Ian Campbell of Noranda Forest Sales (U.K.) Ltd., reported that one of his customers looks for "clean, bright, square packages, true to size and consistently graded," Consistency of sizing, grading and presentation are of strategic marketing importance, Campbell said, "In an increasingly global marketplace, even commodities must aim for enhanced market image.

"Product presentation is not а cosmetic nicety. In building customer support and loyalty, it could be the difference between success and failure:"

Campbell predicted that there will be greater competition for Canadian goods as European countries become more self-sufficient. The market will demand more kiln-dried and MSR lumber. Demand for paper wrapping and value-added products will continue to grow. Expensive items, such as molded or finished products, dried and pre-cut sizes will have to be protected in containers or shipped under deck.

Maximizing output

Efficiency is also known to be а determining factor in the success or failure of а mill. To help members cope with the increasing competition of the industry, а panel discussion on improving efficiency was held on Friday.

Moderator Fred Burrows said mills have to maximize lumber output per metre of roundwood input because lumber prices haven't risen to compensate for increased taxes and lost exchange revenue, Improved drying, thin-kеrf sawing, curve sawing and computer optimized grading were all explored as means of improving efficiency.

There is potential for increased wood recovery with thinner saw blades, but the benefit of thinness is lost if the blade deviates. Because of this, Ken Hall, Mainland Manufacturing, explained, thin-kеrf sawing requires "а total company commitment. No single department of your mill is responsible for thin-kerf sawing - it takes maintenance, production, filing and management working in cooperation to achieve success."

Aside from commitment, other features are necessary for this sawing method. Hall recommends а heavy, solid frame which absorbs vibration. The infeed and outfeed systems must be considered an integral part of the process. The lubrication system becomes more important because thinner saw plates are more sensitive to temperature changes.

Hall stressed that precision and accuracy are crucial. "When purchasing saws, ensure that your manufacturer will hold а consistent thickness tolerance of plus 0, minus 0.001 inches." And remember, he added, "You get what you pay for - pure and simple." He estimated that an edger for thin-kerf sawing would cost $250,000 to $300,000,

Curve sawing is another possibility for increasing fibre recovery. Since logs with sweep can’t be prevented from entering a sawmill, Arthur Selin of Denis Sawmill suggest working with the sweep to get the most out of a log. The system proposed by Selin is relatively simple. It requires a positive centering infeed, electronic scanners and a log turner. The centering infeed can be conical rolls, side tires or two belts; the key is to have it as close as possible to the saws.

The Canadian softwood lumber industry is losing about $130 million annually due to downgrading of kiln-dried, according to Forintek’s Peter Garrahan. He emphasized that the drying process can and must be improved because of the increasing demand for kiln-dried and higher value products.

To ensure that all boards entering the dryer have the same moisture content and the same driving rate, Garrahan suggested sorting wood according to species and moisture content before it is dried. Forintek has a remote sensor that measures moisture content and is suitable for this application.

|

|

The moisture sensor could also be used after drying to determine if the

wood is dry enough. This would serve as an on-line measure of the effectiveness of the dryer and ensure that wood of a consistent moisture content goes to customers. He suggested the moisture content of each board be stamped on it.

To maximize return from every piece of lumber, VisionSmart Inc. has developed a computer-aided lumber grading system. Company President Jim Empey said the system can increase yield by three to seven per cent. The computerized system scans each board and then chooses the solution that gives the highest dollar value. The software considers the current market value for each dimension, length and grade.

Minimal changes for maximum productivity was a central issue at the CLA meeting, and is not one that can be overlooked. It is likely to come up often in the next few years as producers cope with harsh economic conditions and global competition.

9. Переведите письменно рекламные тексты:

Timberjack

|

|

|

Поперечные профили набережных и береговой полосы: На городских территориях берегоукрепление проектируют с учетом технических и экономических требований, но особое значение придают эстетическим...

История развития хранилищ для нефти: Первые склады нефти появились в XVII веке. Они представляли собой землянные ямы-амбара глубиной 4…5 м...

Таксономические единицы (категории) растений: Каждая система классификации состоит из определённых соподчиненных друг другу...

Общие условия выбора системы дренажа: Система дренажа выбирается в зависимости от характера защищаемого...

© cyberpedia.su 2017-2024 - Не является автором материалов. Исключительное право сохранено за автором текста.

Если вы не хотите, чтобы данный материал был у нас на сайте, перейдите по ссылке: Нарушение авторских прав. Мы поможем в написании вашей работы!