Биохимия спиртового брожения: Основу технологии получения пива составляет спиртовое брожение, - при котором сахар превращается...

Кормораздатчик мобильный электрифицированный: схема и процесс работы устройства...

Биохимия спиртового брожения: Основу технологии получения пива составляет спиртовое брожение, - при котором сахар превращается...

Кормораздатчик мобильный электрифицированный: схема и процесс работы устройства...

Топ:

Особенности труда и отдыха в условиях низких температур: К работам при низких температурах на открытом воздухе и в не отапливаемых помещениях допускаются лица не моложе 18 лет, прошедшие...

Методика измерений сопротивления растеканию тока анодного заземления: Анодный заземлитель (анод) – проводник, погруженный в электролитическую среду (грунт, раствор электролита) и подключенный к положительному...

Организация стока поверхностных вод: Наибольшее количество влаги на земном шаре испаряется с поверхности морей и океанов...

Интересное:

Национальное богатство страны и его составляющие: для оценки элементов национального богатства используются...

Берегоукрепление оползневых склонов: На прибрежных склонах основной причиной развития оползневых процессов является подмыв водами рек естественных склонов...

Инженерная защита территорий, зданий и сооружений от опасных геологических процессов: Изучение оползневых явлений, оценка устойчивости склонов и проектирование противооползневых сооружений — актуальнейшие задачи, стоящие перед отечественными...

Дисциплины:

|

из

5.00

|

Заказать работу |

Chapter Y

Mechanical Engineering

In Forestry

Lesson 1

Logging and Woodworking

Terms and expressions

| logging | – лесозаготовки |

| wood | – древесина, лесоматериалы |

| woodworking | – деревообработка |

| growth ring | – годовое кольцо |

| heartwood | – ядровая древесина |

| sapwood | – заболонь древесины |

| renewable | – восстановленный |

| softwood | – хвойная древесина |

| hardwood | – лесоматериалы лиственных пород |

| lumber | – пиломатериалы |

| plywood | – фанера |

| fell trees | – рубить лес |

| timber harvest | – лесозаготовки |

| logs | – бревна |

| sawmills | – лесопильные заводы |

| pulp wood | – древесная целлюлоза |

| pulp and paper industry | – целлюлозно-бумажная промышленность |

| a selection cut | – выборочная рубка леса |

| vernal pools | – весенние заводы |

| riparian zones | – прибрежные зоны |

| tree – length logging | – лесозаготовки с трелевкой хлыстов |

| full – tree logging | – лесозаготовки с трелевкой (вывозкой деревьев) |

| harvester | – лесозаготовительная машина |

| cut–to-length logging | – лесозаготовки длинномерных сортиментов |

| feller buncher | – валочно-пакетирующая машина |

| forwarder | – форвардер (трактор для трелевки лесоматериалов) |

| soil compaction | –уплотнение почвы |

| to reduce ruts | – уменьшать борозды |

| caterpillar tracks | – гусеничный конвейер |

| unsustainable logging | – неустойчивые лесозаготовки |

| carpentry | – плотницкое ремесло |

| joinery | – столярное ремесло |

| turning | – токарная работа |

| carving | – резьба по дереву |

| measuring and marking tools | – измерительные инструменты |

| cutting tools | – режущие инструменты |

| shaping tools | – инструменты для строгальных работ |

| assembly tools | – инструменты для сборки |

| finishing tools | – инструменты для отделки |

| timber bucking | – раскряжевка хлыстов |

Introductory exercises

Переведите следующие предложения на русский язык:

Wood is hard, fibrous material formed by the accumulation of secondary XYLEM produced by the vascular CAMBIUM.

It is the principal strengthening tissue found in the stems and roots of trees and shrubs.

Wood forms around a central core (pith) in a series of concentric layers called growth ring.

A cross section of wood shows the distinction between heartwood and sapwood.

Heartwood, the central portion is darker and composed of xylem cells that are no longer active in the life processes of the tree.

Sapwood, the lighter area surrounding the heartwood, contains actively conducting xylem cells.

Wood is one of the most abundant and versatile natural materials on earth, and unlike cool, ores, and petroleum, is renewable, with proper care.

The most widely used woods come from two groups of trees: the CONIFERS, or SOFTWOODS (e.g., pine, spruce, fir) and the broadleaves, or HARDWOODS (e.g., oak, walnut, maple).

Trees classified as hardwoods are not necessarily harder than softwoods (e.g., BALSA, a hardwood, is one of the softest woods).

Density and moisture content affect the strength of wood; in addition to load–bearing strength, other variable factors often tested include elasticity and toughness.

Wood is insulating to heat and electricity and has desirable acoustical properties.

Some identifying physical characteristics of wood include color, odor, texture, and grain (the direction of the wood fibers).

Some 10,000 different wood products are commercially available, ranging from lumber and plywood to paper, from fine furniture to toothpicks.

Chemically derived products from wood and wood residues include cellophane, charcoal, dyestuffs, explosives, lacquers, and turpentine.

Wood is also used for fuel in many parts of the world.

2. Найдите в тексте и переведите словосочетания:

To fell (cutdown) trees; to supply raw material; wood products; logs for sawmills; the logging contractor; silvicultural system; to plan a selection cut; to mark the trees; to delimb trees; to transport to the landing; to buck logs; large piles of slash; at the stump area; to place logs in bunks; to be brought by the forwarder; to be moved from the stump to the landing; cable systems; a floating log raft; burning logging debris; to release nutrients; manual planting of seedlings; mechanical tree harvesters and forwarders; to cause nutrient depletion; boatbuilding for access to timber, ground based logging operations; the use of heavy machinery; damaged or diseased trees; the long-term productivity of the forest; a source of sediment; the risk of erosion and landslides; woodworking projects; metal fastness; to turn a piece of wood on a lathe; woodworking machinery; to produce a satisfactory finish.

3. Переведите письменно (рекомендуется для зрительно -письменного перевода и пересказа на английском языке):

Logging

Logging is the process in which trees are felled (cut down) usually as part of a timber harvest. Timber is harvested to supply raw material for the wood products industry including logs for sawmills and pulp wood for the pulp and paper industry. Logging can also remove wood for forest management goals. Logging is a controversial due to its environmental and aesthetic impacts.

Logging and forestry. The two main stakeholders in most logging operations are the landowner and the logging contractor. Prior to a large harvest a landowner will often hire a consulting forester. Owners of large industrial tracts may employ their own foresters. During planning for the harvest the forester will determine how best to meet the landowners objectives, including the silvicultural system to be used, even-aged or uneven-aged management, layout of roads and landings. If a selection cut is planned the forester will mark the trees intended to be cut or if a clear cut which blocks are to be harvested. A well-managed forest will be harvested according to a forest management plan. This plan should include areas off-limits to cutting such as sensitive habitat, vernal pools and riparian zones.

Harvest methods. The above operations can be carried out by different

methods, of which the following three are considered industrial methods:

Tree-length logging. Trees are felled and then delimbed and topped at the stump. The log is then transported to the landing, where it is bucked and loaded on a truck. This leaves the slash in the cut area.

Full-tree logging. Trees are felled and transported to the roadside with top and limbs intact. The trees are then delimbed, topped, and bucked at the landing. This method can leave large piles of slash rotting near the road. Full-tree harvesting also refers to utilization of the entire tree including branches and tops.

Cut-to-length logging. Trees are felled, delimbed, bucked, and sorted (pulpwood, sawlog, etc.) at the stump area, leaving limbs and tops in the forest. Harvesters fell the tree, delimb and buck it, and place the resulting logs in bunks to be brought to the landing by the forwarder.

Operations. A timber harvest can consist of the following operations, although not necessarily in the following order.

Pre-logging:

Planning- Identifying optimal timing, access, and layout of harvest.

Permitting- Regulatory review can include public notification, environmental assessment, taxes, and fees.

Sale - Many timberland owners employ their own loggers, while others hire or sell the right to log to a logging company.

Accessing - Logging roads, logging camps, and weighing stations are built or repaired as needed.

Marking - The area or individual trees to be harvested are clearly identified.

Logging:

Felling - The standing tree is cut down or felled by chainsaw, harvester, or feller buncher.

Processing - The tree is turned into logs by removing the limbs (delimbing) and cutting it into logs of optimal length (bucking).

Stump to landing - The felled tree or logs are moved from the stump to the landing. Ground vehicles can pull, carry, or shovel the logs. Cable systems can pull logs to the landing. Logs can also be flown to the landing by helicopter.

Landing to mill - The logs are commonly transported to the mill or port by truck, but in the past, this has been done by train, by driving the logs downstream, or by pulling them as a floating log raft.

Post-logging:

Burning - Burning logging debris and other woody material on the site can reduce future fire risk and release nutrients.

Herbicide - Eliminating competing seedlings and brush to speed growth of the planted seedlings.

Ground preparation - Cultivation of the soil to create suitable planting positions. This operation may include some element of land drainage in wet areas if soil saturation affects seedling survival / growth potential.

Replanting - Dropping seeds or manual planting of seedlings.

Road deconstruction - Subsequent erosion and land sliding from old roads can be reduced by installing waterbars, pulling fill from stream crossings, and putting excavated materials back to reform the original topography.

Logging and safety

Logging is by some measures a dangerous occupation. Loggers work with heavy, moving weights and the use of tools such as chainsaw and heavy equipment in uneven and sometimes unstable terrain. Loggers also deal with severe environmental conditions such as inclement weather and severe heat and cold. An injured logger is often far from professional emergency treatment. The risks experienced in logging operations can be somewhat reduced, where conditions permit, by the use of mechanical tree harvesters and forwarders.

Logging and the environment

Impact of timber harvest. Logging impacts the environment in many

ways, the timber harvest itself, that is, the removal of trees from the forest, and secondly by the disturbance caused by logging operations. Removal of trees alters species composition, the structure of the forest, and can cause nutrient depletion. Harvesting also can lead to habitat loss, prominently in high-value, ecologically sensitive lands. Loss of trees adjacent to streams can increase water temperatures. Harvesting adjacent to streams can increase sedimentation and turbidity in streams, lowering water quality and degrading riparian habitat. Logging roads and operations increase the risk of colonization of forest areas by invasive exotics, especially in the eastern North American hardwood and western evergreen forests (see also Gypsy moth). Some of the most clearly noticeable effects of large-scale clear-cutting, including effects on stream corridors, has been seen in the American Pacific Northwest, where endangered salmon spawning and rearing habitat has been damaged. A forest managed primarily for wood production will typically consist of young, vigorous, fast-growing trees. Such a forest may lack areas with late-succession characteristics, including older trees, required by some species. Good forest management requires that such areas be set aside to protect species that may be rare or endangered. Roadbuilding for access to timber in frontier forests often opens up areas previously not accessible, which facilitates further development such as farming.

Impact of logging operations. Modern ground based logging operations require the use of heavy machinery in the forest. In some areas roads must be built which often causes habitat fragmentation and increased edge effect. The use of heavy machinery in a forest can cause soil compaction. Harvesting on steep slopes can lead to erosion, landslides, and water turbidity. Logging on saturated soils can cause ruts and change drainage patterns. Harvest activity near wetlands or vernal pools can degrade the habitat. Forest machines use oils which, if not handled carefully, can cause pollution.

These problems can be mitigated by using low - impact logging and best

management practices, which set standards for reducing erosion from roads. Damage to streams and lakes can be reduced by not harvesting riparian strips. Ecologically important lands are sometimes set aside as reserves.

Logging can also have positive effects on the environment by removing damaged or diseased trees or both, and opening up the canopy to promote growth of smaller, healthier trees. Branches, snags, and other non-marketable parts of the tree provide shelter for wildlife. Underbrush that would not otherwise grow due to lack of sunlight thrives, and is an important food source for browsing mammals. Select cutting can improve the forest and bring to market trees that would otherwise decompose. Technological advances in logging equipment are reducing ruts and soil disturbance. Processors and Forwarders with Caterpillar tracks or other designs to lower ground pressure help to reduce machine impact.

Woodworking

Woodworking is the process of building, making or carving something using wood.

History. Along with stone, mud, and animal parts, wood was certainly one of the first materials worked by primitive human beings. Microwear analysis of the Mousterian stone tools used by the Neanderthals show that many were used to work wood. Indeed, the development of civilization was closely tied to the development of

increasingly greater degrees of skill in working these materials.

Among early finds of wooden tools are the worked sticks from Kalambo Falls, Clacton-on-Sea and Lehringen. The spears from Schoningen (Germany) provide some of the first examples of wooden hunting gear. Flint tools were used for carving. Since Neolithic times, carved wooden vessels are known, for example from the Linear Pottery culture wells at Kückhofen and Eythra. Examples of Bronze Age wood-carving include trees worked into coffins from northern Germany and Denmark, and wooden folding-chairs. The site of Fellbach-Schmieden in Germany has provided fine examples of wooden animal statues from the Iron Age. Wooden idols from the La Tène period are known from a sanctuary at the source of the Seine in France.

Two ancient civilizations that used woodworking were the Egyptians and the Chinese. Woodworking is depicted in many ancient Egyptian drawings, and a considerable amount of ancient Egyptian furniture (such as stools, chairs, tables, beds, chests) has been preserved in tombs. As well, the inner coffins found in the tombs were also made of wood. The metal used by the Egyptians for woodworking tools was originally copper and eventually, after 2000 BC bronze as ironworking was unknown until much later.(1) Commonly used woodworking tools included axes, adzes, chisels, pull saws, and bow drills. Mortise and tenon joints are attested from the earliest Presynastic period. These joints were strengthened using pegs, dowels and leather or cord lashings. Animal glue came to be used only in the New Kingdom period.(2)Ancient Egyptians invented the art of veneering and used varnishes whose composition is not known as finishes. Although different native acacias were used, as was the wood from the local sycomore and tamarisk trees, deforestation in the Nile valley resulted in the need for importation of wood, notably cedar, but also Aleppo pine, boxwood and oak, starting from the Second Dynasty.(3)

The progenitors of Chinese woodworking are considered to be Lu Ban and his wife Lady Yun, from the Spring and Autumn Period. Lu Ban is said to have brought the plane, chalkline, and other tools to China. His teachings are supposedly left behind in the book Lu Ban Jing ("Manuscript of Lu Ban"), although it was written some 1500 years after his death. This book is filled largely with descriptions of dimensions for use in building various items - such as flower pots, tables, altars, etc. - and also contains extensive instructions concerning Feng Shui, the ancient Chinese practice of geomancy. It mentions almost nothing of the intricate glueless and nailless joinery for which Chinese furniture was so famous.

Topics in woodworking

Woodworking is now a general term covering a wide range of skills and techniques.

carpentry - Originally a carpenter was a wagon maker but carpentry has come to mean the general working of wood. Sometimes used to cover all aspects of woodworking, at other times carpentry refers to the least-skilled level of woodworking and larger projects, such as house building.

joinery - Either refers to (mainly in the UK) architectural woodwork or (mainly in the USA) to the joining of two or more pieces of wood together, necessary in most woodworking projects. Also used particularly to refer to the joining of wood without the use of nails, screws, or other metal fasteners.

cabinetry, cabinet making, cabinetmaker - The practice of utilizing many woodworking skills to create cabinets, shelving and furniture; a craftsman who specializes in the making of fine furniture. Implies a very high level of skill in woodworking.

marquetry and parquetry - The practice of creating patterns by inlaying different wood veneers; with different colours and different grains complex patterns are formed. Originally used to decorate furniture, both are now often used to produce pictures. Often regarded as a fine art form, equal to sculpture and painting. Marquetry is distinguished from parquetry by the shapes used and formed - marquetry entails the creation of organic or scenic pictures, while parquetry involves geometric shapes.

turning - The art of turning a piece of wood on a lathe and shaping it by holding various cutting tools against it. Segmented turning is a combination of parquetry and turning.

wood species - Choosing which type (species) of wood is correct for a given project.

carving.

boat building - Professionally done by shipwrights.

luthier - someone who builds or repairs stringed musical instruments such as guitars or violins.

wheelwright - A maker of wooden wheels and spokes.

cooper- A maker of casks and barrels.

bodger - Now archaic, a wood-turner specializing making furniture and treen. Also a corruption of "botcher", a colloquial term for an incompetent workman.

patternmaker - a maker of wooden patterns used to create moulds for sand casting. A highly precise type of woodworking, the patternmaker must not only make the pattern to exacting standards, but also allow for metal shrinkage while cooling.

Some of these refer to special techniques such as marquetry or turning, while others refer to a specialized product such as the cooper or wheelwright.

Woodworking tools

A variety of tools are used for woodworking. These may be divided into hand tools and power tools or woodworking machinery, or they may be divided into rough groups based on their function in the woodworking process.

Measuring and marking tools:

rulers, tape measures, and protractors;

straightedges, combination squares, try squares;

scratch awls, marking gauges, marking knives;

levels;

plane gauges used to determine the flatness of a surface;

hygrometers used to determine the water content of wood before and during working;

winding sticks used to assist when flattening boards.

Cutting tools:

hand saws such as the crosscut saw, rip saw, various hacksaws (tenon saw, dovetail saw, gent's saw), coping saw, keyhole saw, bow saw, and various Japanese saws;

power saws such as the circular saw, chainsaw, table saw, radial arm saw, jigsaw, miter saw, hole saw (actually a form of drill bit), band saw and scroll saw.

Shaping tools

hand planes such as the jointer plane, smoothing plane, block plane, shoulder plane, scrub plane, spear plane, and rabbet plane;

thickness planer and jointer;

router and router bits;

rotary tools, often known by the trade name 'Dremel';

chisel and gouge;

lathe;

drill press and hollow chisel mortiser;

rasp;

knife;

Other hand shaping tools, such as the axe, adze, froe, spokeshave, and drawknife.

Assembly tools:

screwdriver;

hammer and mallet;

hand or power drills along with drill bits;

clamps including the C-clamp, F-clamp, G-clamp, bar clamp, mitre clamp, sash clamp and band clamp

Finishing tools:

sandpaper, used alone or with sanding blocks or power sanders such as the belt sander, palm sander, disc sander, and random orbit sander;

steel wool or bronze wool, used for polishing or applying stain or liquid finishing compounds;

file;

scraper;

brushes mainly for applying varnish, wood stain;

spray guns for applying lacquer.

Accessory tools and furniture:

Workbench or just bench is a high table at which one usually stands or sits on a high stool, and on which wood is worked;

- dog hole, a square or round hole made in the top surface of a bench to allow the attachment of various clamping and holding devices;

- bench dog, a peg which, when fitted into a dog hole allows clamping pressure to be applied to a wooden item being worked;

- hold fast, a simple bent rod with a foot which when placed in a dog hole in a bench can be used to position and hold boards;

- vise, or vice, a stable clamping apparatus used to hold wood in different positions while being worked;

- bench hook, a bench top stop against which wood can be pushed whilst being worked.

Sawhorse, a four-legged stand usually used in pairs to support large pieces of wood such as panels, long boards, and sheets.

Horse, also known as a shave horse, a tool upon which one sits, with a

foot activated clamp to hold shingles, spokes, or short boards, upon which one shaves wood with a drawknife or spokeshave.

Shooting board, used in combination with a hand plane to trim end grain or to straighten edges of boards.

Tool sharpening

The cutting and some of the shaping woodworking tools rely upon sharp cutting edges to produce a satisfactory finish. Keeping these tools sharp is an important aspect of woodworking. There are a large number of machine powered and hand powered sharpening methods in use by woodworkers, the selection of which is in part determined by the tool being sharpened and part personal preference. Some tools, such as chisels and plane blades, are commonly sharpened by the owner, others, such as saw blades and machinery knives, are more often sent to a sharpening specialist.

Sharpening paraphernalia:

diamond plate;

file;

grinder;

saw set;

sharpening jig;

waterstone;

whetstone or oil stone;

grinding dresser.

4. Переведите вопросы и ответьте на них:

What is logging?

Why is timber harvested?

What types of cut can be planned by a forester?

What are three harvest methods?

What operations can a timber harvest consist of?

Why is logging considered to be a dangerous occupation?

How can the risks experienced in logging operations be reduced?

What is the influence of timber harvest on the environment?

What can the use of heavy machinery in the forest cause?

What topics are there in woodworking?

Could you name the groups of woodworking tools, please?

5. Переведите на слух:

Wood products; целлюлозно-бумажная промышленность; to remove woods; прибрежные зоны; to delimb trees; древесная целлюлоза; to be brought by the forwarder; лесозаготовительные участки; to build weighing stations; вырубать валочно-пакетирующей машиной; to turn a tree into logs; раскряжевка хлыстов; to pull logs to the landing; сплав леса по воде; burning logging debris; ускорить рост высаженных саженцев; cultivation of the soil; осушение земель в заболоченных районах; to work with heavy, moving weights; пересеченная местность; endangered species; лесозаготовки на насыщенной почве; to remove damaged or diseased trees.

6.Переведите устно (рекомендуется для перевода с «листа» с подготовкой):

Lesson 2

Terms and expression

| mechanical engineering | – машиностроение |

| component | – часть, деталь |

| dismantle | – разбирать, демонтировать |

| bolt | – болт |

| shank | – стержень, корпус, тело (болта) |

| head | – головка (болта) |

| screw-threaded | – нарезной, имеющий винтовую нарезку |

| nut | – гайка |

| washer | – шайба |

| cushion | – упругая прокладка, подушка, амортизатор |

| workpiece (work) | – обрабатываемая деталь, заготовка |

| square-headed bolt | – болт с квадратной головкой |

| cup-headed bolt | – болт с полукруглой головкой |

| countersunk head bolt | – болт с потайной головкой |

| hexagonal nut | – шестиугольная гайка |

| square nut | – квадратная гайка |

| wing nut | – барашковая гайка |

| lock nut | – контргайка |

| split pin | – шплинт |

| rivet | – заклепка |

| welding | – сварка |

| key | – шпонка |

| shaft | – вал |

| pulley | – блок, ролик |

| gear (-wheel) | – зубчатое колесо, шестерня |

| axle | – ось, мост (автомобиля) |

| spindle | – шпиндель; ось; стержень |

| crankshaft | – коленчатый вал, кривошип |

| camshaft | – кулачковый вал, распределительный вал |

| splined shaft | – шлицевый вал |

| bearing | – подшипник |

| journal | – шейка; цапфа; пята |

| pedestal | – опорная подкладка, подушка; нормальный трансмиссионный подшипник |

| ball bearing | – шариковый подшипник |

| roller-race bearing | – роликовый подшипник |

| outer race | – наружная обойма |

| inner race | – внутренняя обойма |

| ball cage | – сепаратор шарикоподшипника, шариковая обойма |

| power transmission system | – силовая трансмиссия |

| mechanical drive | – механический привод |

| prime mover | – двигатель; тягач |

| transmission by friction | – передача трением |

| friction drive | – фрикционный привод |

| belt drive | – ременный привод |

| mesh | – зацепление |

| tooth(ed) gear | – зубчатое колесо; зубчатая передача |

| worm gear | – червячное колесо; червячная передача |

| chain drive | – цепной привод |

| coupling | – муфта, соединение |

| clutch | – разъемная муфта |

| rigid coupling | – жесткая муфта |

| flexible coupling | – упругая муфта |

| claw (jaw) type coupling | – кулачковая муфта |

| flanged coupling | – фланцевая муфта; фланцевое соединение |

| universal coupling | – универсальная муфта, кардан |

| disc-type coupling | – дисковая муфта |

| hydraulic-type coupling | – гидравлическая муфта |

| disc-type friction coupling | – дисковая раздвижная муфта, фрикцион |

| cone-type friction clutch | – конический фрикцион |

| safety clutch | – предохранительная муфта |

| gearing | – передача (зубчатая) |

| spur-type gear | – цилиндрическое прямозубое колесо |

| bevel gear | – коническое зубчатое колесо |

| worm gearing | – червячная канитель |

| lathe | – токарный станок |

| machine | – станок, механизм, машина |

| steel bar | – стальная болванка (стержень) |

| pivot | – точка опоры; ось вращения; малая ось; стержень |

| centers | – центры (станка) |

| cutting tool | – резец |

| machining work | – обработка (на станке) |

| turning | – токарная обработка, обточка |

| framework | – станина |

| cast iron | – чугун |

| bed | – стол |

| tool-slide rest | – (крестовый, сложный) суппорт, суппорт с поворотными верхними салазками |

| tool-post | – резцедержатель |

| headstock | – передняя бабка |

| tailstock | – задняя бабка |

| screw-cutting lathe | – токарно-винторезный станок |

| turret lathe | – токарно-револьверный станок |

| roughing tool | – обдирный резец |

| facing tool | – подрезной (токарный) резец; боковой (строгальный) резец |

| parting tool | – отрезной резец |

| planning machine | – строгальный станок |

| milling machine | – фрезерный станок |

| grinding machine | – шлифовальный станок, заготовительный станок |

| in repair work | – при ремонтных работах |

| to form a cushion | – создавать упругую прокладку, подкладку, амортизировать |

| to prevent nuts from working loose | – предупреждать самоотвинчивание гаек |

| to secure an object in position | – прочно закреплять предмет |

| to be meshed together | – быть в зацеплении друг с другом |

| to move at a uniform speed to and fro lengthways | – двигаться с равномерной скоростью взад и вперед вдоль (заготовки) |

| to operate a tool | – работать резцом (инструментом) |

| to machine a workpiece | – обрабатывать деталь (заготовку) |

Commentary

1. Among the English terms which convey the notion of деталь машины one may come across such terms as machine component, machine part or machine element. All the three word combinations are synonymous, although machine element is preferable. In some other combinations the words component, part and element are not always interchangeable e.g. axial component – осевая направляющая; spare part – запчасть.

2. Washer, spacer, gasket. The term washer – шайба, прокладка –

denotes the machine element used to prevent nuts or bolts from getting loose.

Spacer – распорная деталь, прокладка, шайба. Its main purpose is to facilitate the tightening of the parts fastened to each other.

Gasket – прокладка, набивка, уплотнение – implies the element preventing leakage of liquids or escape of gases, e.g. a gasket is laid between the cylinder block and the block head in the internal combustion engine.

3. Bearing, pedestal. The former is polysemantic and implies the notions of подшипник, опора, пеленг, азимут, etc. Still greater is the number of terminological word combinations with the bearing. The most common of them are ball bearing – шариковый подшипник, roller bearing – роликовый подшипник.

In addition to the meaning of подшипник, the term pedestal conveys the notions of подставка, опорная подкладка, основная база, стойка, буковая челюсть (ж. д.). The terms many combine with each, e.g. pedestal bearing – подшипник на стойке.

4. Translators often confuse the terms axis, axle, shaft, each of which may be translated by the Russian term ось.

The term axis however denotes the geometric, spatial, imaginary line e.g.

magnetic axis – магнитная ось, optical axis – оптическая ось, etc.

The term axle means a material object, a machine, component, e.g.

guiding axle – ведущая ось, car axle – вагонная ось, axle – задний мост (e.g., of a car).

Shaft – is the most suitable term to convey the Russian notions of ось or вал. It may also mean стержень, шпиль, шахта (подъемника), тяга, привод, рукоятка, ручка. Most common are the combinations in which shaft means вал, e, g, drive shaft – ведущий вал, crankshaft – коленчатый вал, flexible shaft – гибкий вал.

5. Gear. The term implies a dozen of notions and forms more than 250

terminological word combinations (See the English-Russian Technical Dictionary).

The principal notions it conveys are: шестерня, зубчатая передача, зубчатое колесо, привод, механизм, приспособление, устройство, инструмент, шасси (ав.), оснастка. Syn.: gear wheel, tooth(ed) gear, pinion (малое зубчатое колесо пары), drive, device, unit, etc.

Introductory exercises

Engineering Materials

1. Materials used in mechanical engineering consist chiefly of metals, alloys and plastics, which have almost completely replaced timber, largely used in the past. Rubber is employed for some purposes — mainly for fittings, packings, and washers. Leather is also used for washers, pump-plungers and driving belts.

2. Metals of various types and their alloys are by far the most widely used materials. One of the oldest is cast iron, which is made from iron-ore by smelting it in a kiln or chamber, called a "blast furnace". Run off into sand moulds and cooled, the cast iron forms blocks called pigs.

3. Cast iron is strong in compression but weak in tension. It is therefore used for making bases for machinery, stands, engine bed-plates, framework for machines, brackets, pedestal bodies, bearing-housings, gear-wheels, pulleys, intricate casings for machinery, engine cylinders, domestic utensils, fire-grades and architectural fittings of an ornamental nature, or, anything in which tensile stress is not involved.

4. Steel is produced by melting cast iron (pigs) and refining it to remove some of the carbon and other impurities.

Special kinds of steel comprise mild or structural steel, alloy steel, stainless steel, carbon (or tool) steel, self-(or air-) hardening tool steel, heat-resisting steel, and many others.

5. One method of preventing a nut from loosening is to fit what is termed a spring washer. There are several forms of these, and each claims its particular merit. When placed in position on a bolt, and the nut screwed on, the reaction of the spring, as it is compressed, exerts pressure against the nut and prevents the latter from turning and working loose.

6. When two shafts have their axes set at right angles to each other, the shafts may be driven, or rotated by the use of bevel gears. If it is desired to rotate one shaft at a different speed from the other, a bevel gear-wheel and bevel pinion would be used.

7. A screw-cutting lathe differs from a plain, or surfacing sliding lathe, for it must be arranged to provide uniform travel for the saddle along the bed carrying the slide-rest at various speeds to suit the pitch of screw-thread to be formed.

2. Найдите в тексте и переведите словосочетания:

1. Машиностроение, части машин пружинная шайба, быть в зацеплении, предотвращать самоотвинчивание гаек, шплинт, заклепка, муфта, роликовый подшипник, привод, токарный станок, червячная передача, фрезерный станок, демонтировать, деталь, стержень, нарезной, механический привод, заготовка, обработка, обдирный резец, строгальный станок, прокладка.

2. Outer race, ball cage, gearing, pivot, riveting, universal coupling, friction clutch, to operate a tool, to machine a workpiece, gear wheel, screw-threaded, to reduce the velocity of driven shafts, shank, milling machine, lathe, safety, clutch. Worm gearing, mesh, roller-race bearing, split pin.

3. Переведите устно и письменно (может использоваться для последовательного перевода):

Муфты

Муфты служат для соединения(7) валов или других вращающихся деталей. Муфты в современном машиностроении(8) необходимы почти во всех машинах. Соединение валов турбины и генератора, двигателя(9) и рабочей машины, валов отдельных узлов(10) и агрегатов; управление машиной - плавный или мгновенный пуск, остановка, реверсирование и переключение скорости; предохранение от перегрузки, «разноса» или обратного вращения – все эти и многие другие функции в современных машинах выполняются муфтами(11).

Этим объясняется огромное разнообразие известных типов муфт и непрерывное появление новых конструкций.

Сцепные муфты служат для сцепления(12) и расцепления валов во время их совместного вращения (на ходу) или во время остановки (в покое). По характеру сил сцепления эти муфты можно разделить на четыре группы: фрикционные; кулачковые (зубчатые), электромагнитные (жидкостные и порошковые); гидромуфты. По способу управления сцепные муфты подразделяются на управляемые усилием человека непосредственно или с использованием вспомогательной энергии и самоуправляемые.

Couplings and Clutches

Couplings and clutch are intended to connect shafts or other revolving parts and in modern mechanical engineering they form integral components of almost all machines. Coupling and clutches link together the shafts of turbines and generators, prime movers and driving mechanisms, as well as the shafts of separate units and assemblies, effect smooth or instantaneous starting(6), stepping, reversing and gear change(7) of machines; protect against overload and racing and prevent reverse rotation.

Hence the great diversity of types of couplings and clutches and the continuous development of new designs.

Clutches are employed to connect and disconnect shafts during their relative motion (under load) or at standstill. According to the forces which keep them engaged(8), clutches may be divided into four groups: friction, claw (toothed, electromagnetic fluid and electromagnetic powder, and hydraulic clutches. Depending on the manner in which clutches are operated they are

subdivided into those controlled by an operator directly or by means of

auxiliary force, and power controlled clutches.

Преимущества сварных конструкций (13) перед клепаными

Применение сварки вместо клепки для осуществления неразъемных соединений частей машин имеет ряд преимуществ. Главные из них – экономия металла и уменьшение трудоемкости(14). Экономия металла достигается благодаря:

а) меньшему весу соединяемых элементов при сварке (всех сварных швов(15) составляет 1-1,5% от веса конструкций, а вес заклепок – 3,5 – 4%); б) лучшему использованию металла вследствие отсутствия отверстий, ослабляющих рабочие сечения;

в) возможности широкого применения стыковых швов, не требующих дополнительных элементов в виде наклепок.

Применение сварки вместо клепки дает экономию в весе в среднем от 10 до 20 процентов.

Уменьшение трудоемкости обусловлено отсутствием операций разметки, пробивки или сверления отверстий. Кроме того, процесс клепки значительно сложнее и менее производителен, чем процесс сварки, который к тому же во многих случаях может быть автоматизирован.

Commentary

Part A

1. Шпилька may be translated as pin stud; шпилька с резьбой - stud.

2. Конструкция (построение, строительство и в др. знач.) is usually conveyed аs construction. However the notions of структура, конструктивная разработка, детальный проект, устройство; принцип действия, проект, эскиз аге conveyed by the term design.

3. Нарезанный is usually translated as threaded. If the machine component is provided with inner threads it is referred to as а tapped one.

4. Замыкающий in the meaning контровочный, запирающий is translated as locking.

5. Силовая цепь соединения. The word, by word translation can only distort the meaning. The translator has solved the problem expanding the notion and selecting the word system.

6. The word combinations like для соединения are usually translated by the infinitive, е. g. to fasten … The synonymous verbs - to joint, to connect, to couple.

7. Тo translate the word - машиностроение the combinations machine building, machine construction may be used, leave аlone mechanical engineering.

8. Двигатель. One should remember that электрический двигатель

must be translated as motor, whereas двигатель внутренн e го сгорания – as

internal combustion engine, реактивный двигатель as – jet engine. In the

extract the word двигатель is translated as prime m о v е r since the term implies

аn integral machine component in contrast to its working part - the driving mechanism.

9. Узел. The term is polysemantic. It is used in physics, mathematics, botany, geology, army. According to one of the definitions it is an aggregate of interconnected mechanisms found within a limited space. It may also mean составная деталь, сборная часть машины and should therefore be translated as unit, assembly, group.

10. Муфта. Those which may be disconnected are usually termed clutches, e.g. муфта сцепления автомобиля – main clutch; фрикционное сцепление – friction clutch. Various sort of rigid joints (жесткие муфты) and connections are usually referred to as couplings.

11. Сцепление. The word is polysemantic and may be translated as traction (сцепление с грунтом), cohesion (сцепление частиц), clutch (муфта сцепления), meshing (зацепление зубьев шестерен), connection (соединение). The latter is the actual meaning of the word in the extract.

12. Св a рная конструкция. In addition to welder work it may be translated as welder piece, welded structure.

13. Уменьшение трудоемкости – economy of labour, labour saving. 14. Шов. In surgery, sewing – seam, in welding – weld, weld seam.

Part B

Design – план, набросок, устройство. Термин не является синонимом к construction, который обозначает процесс или результат осуществления конструкции – design.

2. Обратите внимание на предлоги: to screw into - ввинчивать в…, to screw onto (or to engage) – навинчивать на ….

3. Fastened parts. Ввиду отсутствия в английском языке причастия

несовершенного вида страдательного залога, сочетание может означать в

зависимости от контекста как скрепление, так и скрепление детали.

4. Instantaneous starting. Отлагательное существительное обозначает в данном контексте процесс. Для обозначения отдельного пуска или места старта используется термин start.

5. Gear change. Устойчивое словосочетание со значениями перемена, переключение скоростей.

6. Engage. Следует помнить, что глагол является одновременно переходным и непереходным.

7. Section. Для обозначения понятия поперечное сочетание обычно используется термин cross section.

7. Переведите письменно:

1. Болт представляет собой стержень с головкой и резьбой, на которую навинчивается гайка. На болт обычно надевается круглая шайба.

Для предупреждения самоотвинчивания гаек существуют контргайки, шплинты, пружинные шайбы и т.д.

Шпонки служат, чтобы неподвижно закреплять на валу шкивы, колеса или шестерни. Для соединения валов применяются различные муфты. Наиболее распространенными из них являются кулачковые, предохранительные, гидравлические и т.д.

Из-за трудности включения на ходу кулачковых муфт вместо них обычно применяются сцепные фрикционные муфты дискового или конического типа.

2. Токарный станок служит для обработки металлов резанием. Он состоит из станины, суппорта, резцедержателя, передней и задней бабок и шпинделя. Существует много различных видов токарных станков – токарно-винторезные, токарно-револьверные и др.

Кроме токарных станков, для обработки металлов применяются строгальные, фрезерные, шлифовальные и многие другие станки.

3.Механическими передачами называются механизмы, предназначенные для передачи энергии от двигателя к рабочим органам машины. Механические передачи по способу передачи от ведущего элемента ведомому разделяются на: а) передачи трением с непосредственным касанием (фрикционные) или с гибкой связью (ременные); б) передачи зацеплением – с непосредственным контактом (зубчатые и червячные) и цепные.

8.Переведите текст (рекомендуется для зрительно-устного и зрительно-письменного перевода):

Painful slowdown

Further economic insight came in an indirect way from Coopers & Lybrand's Chief Economist, Maureen Farrow, during Thursday's luncheon. Farrow's speech was read by Hickey because bad weather kept her from reaching Montreal in time. She was cautiously optimistic about the next few years. "What I am predicting then is a coasting period, not a full-blown recession," she said. She expects a slowdown in the North American economy that could "be quite painful".

Farrow noted that interest rates, the exchange rate and U.S. housing starts are key variables for 1990. She predicts the Canadian dollar will trade at 82 to 83 cents U.S. for the next year, giving the Bank of Canada room to lower interest rates which recently hit a five-year high. As for housing starts, the probability of lower interest rates and lower mortgages points to better times ahead. For the long term, she suggested increased research and development in the fields of converting and value-added products.

She urged companies to make their move early and be proactive on both the global and environmental fronts. The industry needs to raise its profile on environmental matters because the public is watching it closely.

Another luncheon surprise was the winner of the 1990 Wood Award – jack McCracken. The CLA’s executive director looked fist shocked and then embarrassed as the litany of his achievements went on. When presenting the award, Hickey called him “a true leader of our industry”. In addition to guiding the CLA, McCracken is a director of the Canada Wood Council and Canadian Forest Industries Council, and president of the Canadian Lumber Standards Accreditation Board.

Caught unaware, McCracken’s thank you was brief. “I’ve enjoyed my service with you,” he said. McCracken retires at the end of 1990 and will be succeeded by Robert Rivard.

Not merely cosmetic

“It’s time for us to stop selling commodities and start selling a product,” Jacques Boudreau, Lulumco Inc., told the audience at Thursday morning’s panel discussion on Presentation of Product in the Marketplace. This sentiment was echoed by the other panelists, who encouraged mills to concentrate on both quality and packaging in order to enhance their image. “To speak of presentation is really to speak of quality,” said Pierre Bergeron of Scierie des Outardes.

A positive first impression goes а long way with our and customers.” Georgia-Pacific Corp’s Philip Rossmeisl agreed. “They are very pleased when a truck or rail car arrives in their yard in good condition, clearly identified and uniformly packaged. It makes the process of handling. Storing and re-shipping that much easier”.

Presenting the panel with a customer’s point of view, Rossmeisl suggested that standards be developed, such as green paint for the identification of green lumber and red paint for kiln-dried material. He added that timeliness and protection are important aspect of shipping.

Overseas shipping requires special consideration, said Bergeron, sales director. Overseas Markets, for Scierie des Outardes. Bundles may be handled eight or 10 times before reaching their final destination and they must be sturdy enough to stand up to this treatment. One panelist said forklifts sometimes drive on bundles stored under the deck. Bundles must also meet the specifications of the buyer’s country. Bergeron suggested exporters use bearers to facilitate handling, end painting and clear mill identification.

“Environmental issues have only started to influence customers’ attitudes,” Bergeron warned. Plastic wrapping for kiln-dried wood may fall out the horizon is bar coding, which Bergeron said may become necessary for international shipping.

Representing the European point of view, Ian Campbell of Noranda Forest Sales (U.K.) Ltd., reported that one of his customers looks for "clean, bright, square packages, true to size and consistently graded," Consistency of sizing, grading and presentation are of strategic marketing importance, Campbell said, "In an increasingly global marketplace, even commodities must aim for enhanced market image.

"Product presentation is not а cosmetic nicety. In building customer support and loyalty, it could be the difference between success and failure:"

Campbell predicted that there will be greater competition for Canadian goods as European countries become more self-sufficient. The market will demand more kiln-dried and MSR lumber. Demand for paper wrapping and value-added products will continue to grow. Expensive items, such as molded or finished products, dried and pre-cut sizes will have to be protected in containers or shipped under deck.

Maximizing output

Efficiency is also known to be а determining factor in the success or failure of а mill. To help members cope with the increasing competition of the industry, а panel discussion on improving efficiency was held on Friday.

Moderator Fred Burrows said mills have to maximize lumber output per metre of roundwood input because lumber prices haven't risen to compensate for increased taxes and lost exchange revenue, Improved drying, thin-kеrf sawing, curve sawing and computer optimized grading were all explored as means of improving efficiency.

There is potential for increased wood recovery with thinner saw bl

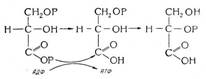

Опора деревянной одностоечной и способы укрепление угловых опор: Опоры ВЛ - конструкции, предназначенные для поддерживания проводов на необходимой высоте над землей, водой...

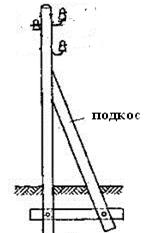

Двойное оплодотворение у цветковых растений: Оплодотворение - это процесс слияния мужской и женской половых клеток с образованием зиготы...

Механическое удерживание земляных масс: Механическое удерживание земляных масс на склоне обеспечивают контрфорсными сооружениями различных конструкций...

История создания датчика движения: Первый прибор для обнаружения движения был изобретен немецким физиком Генрихом Герцем...

© cyberpedia.su 2017-2024 - Не является автором материалов. Исключительное право сохранено за автором текста.

Если вы не хотите, чтобы данный материал был у нас на сайте, перейдите по ссылке: Нарушение авторских прав. Мы поможем в написании вашей работы!