The decommissioning of a nuclear facility is generally categorized into a number of stages. The International Atomic Energy Agency (IAEA) originally defined three stages. In practice, these stages have been adapted for specific facilities and activities can be described broadly as follows:

· Plant Cleanout

· Decontamination

· • Dismantling

· Demolition and Site Clearance

Dismantling

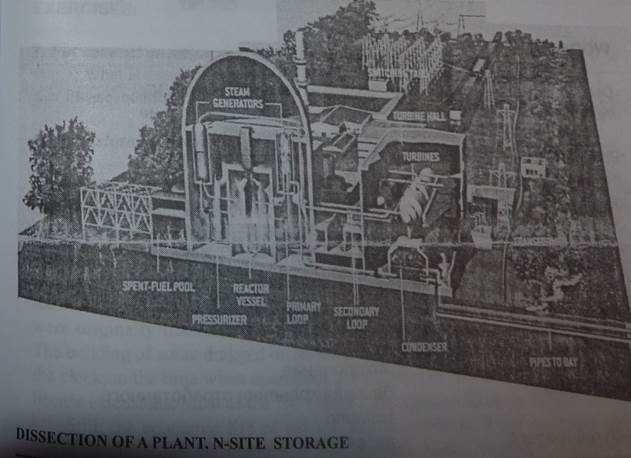

Following decontamination of the facility concerned, equipment within the facility may be dismantled Likewise, equipment within the building(s) on the non-radioactive side of ihe facility (such as offices, turbine halls) can be removed for possible re-use, and the building(s) themselves demolished.

Nuclear Reactors: All equipment and buildings outside the reactor building (e.g. the turbines and turbine hall) may be dismantled. With the reactor sealed and monitored, the rest of the site can be released for re-use.

Fuel-Processing Facilities: Extensive plant decontamination, partial dismantling and removal of plant systems are carried out. As a result of decontamination and dis-manding of equipment, the reduced radiation levels may result in a change of status (for example in France, from a Basic Nuclear Installation to an Installation on the Environmental List), the plant can then be used for non-nuclear purposes

Demolition and Site Clearance

Nuclear Reactors: the final stage of reactor dismantling is completed, buildings demolished and radioactive wastes removed to storage or disposal facilities. The site may risen be delicensed and released for appropriate alternative use. No further inspection or monitoring is required.

Fuel-Processing Facilities: Final dismantling and demolition of the plant is carried out Depending on the specific circumstances there may also be removal of foundations and the free release of the site for appropriate alternative use.

Mines and Mills: Most of the site can be released without further constraint. Depending upon the tailings disposal method, there may be some limit placed on future land use in the tailings area. This generally represents a small fraction of the entire site.

In practice, the extent to which buildings are demolished and the site cleared, following decontamination and dismantling, is dependent on the decommissioning strategy and in some cases, the owner's purposes of re-using the site.

Decontamination in Action

AS IT TURNS OUT, "decommissioning" does not mean "neutralizing"; it means moving radioactive material from one place to another. At Maine Yankee, that means 233 million pounds of waste, of which 150 million pounds is concrete. A little more than half the waste, 130 million pounds, is radioactive. Younger plants have 50 percent more generating capacity than older ones, and their debris volume will be somewhat larger.

There was a plan to sharply cut the amount of waste со be moved around. Originally, Maine Yankee's owners wanted to "rubbleize" the concrete and dump it into the building's foundation, then pour in more concrete to make a monolith. But local law blocks such burials of nuclear waste without a statewide referendum. So instead the plant is literally going away, at a rate of about a trainload a week. In doing so, it is demonstrating both the pitfalls and the ease of decommissioning.

At the site, on a saltwater peninsula south of town where herons nest on power pylons, giant earth-moving equipment has torn up the nonnuclear buildings and loaded the concrete and metal onto railcars. The open gondolas are headed for nuclear dumps in South Carolina or Utah or for a nonnuclear landfill for construction debris in Niagara

County, New York.

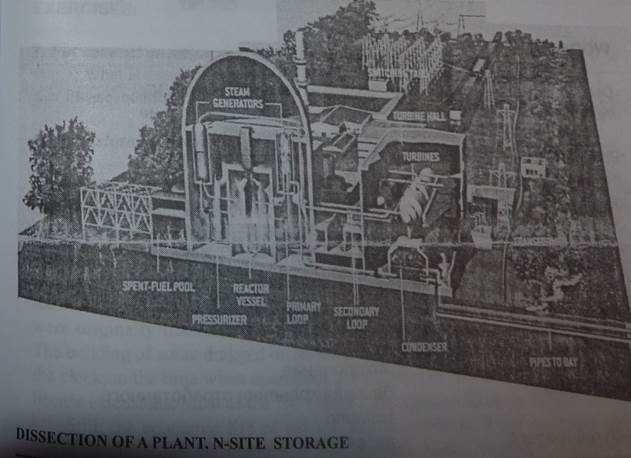

The anatomy of the plant is laid out a bit like that of a frog being dissected in a high school biology lab. During this visit the massive containment dome stands at the edge of a tangle of wreckage that used to be the turbine hall, where the energy in nuclear-heated steam was converted into torque for an electric generator: The path through which the reactor 's product once traveled is plainly visible. Three pipes, each about the size of a water main, emerge from the containment building wall. They conveyed 500-degree-Fahrenheit steam to the turbines at more than 1,000 pounds per square inch of pressure. Underneath each pipe is a larger one that carried water back again for reheating. These were once monitored intensely for signs of radioactive contamination or fluctuations in temperature or flow. Now they sit open to the breeze, waiting their turn to move into the gondolas.

The dome is a tougher challenge. It is a typical containment for a large nuclear plant, big enough to enclose a high school gymnasium. It is four feet thick at the bottom, tapering to two feet at the top, with concentric layers of steel reinforcing bars It weighs about 62 million pounds.

To get the major components out of the dome, workers used a diamond saw. The concrete on the outside surface of the dome has the texture of a driveway. But where blocks have been removed, it feels as smooth as a lacquered coffee table. "Making the first few cuts into a nuclear-related safety system was very difficult to do, knowing it would never come back," says Michael J. Meisner, the chief nuclear officer*on the project. In what was designed to be airtight even at 50 pounds per square inch of overpressure, a rough plywood door, fastened shut with a padlock, gives a little in the occasional breezes.

Although it seems counterintuitive, one of the easiest tasks thus far has been removing the main nuclear components, such as the reactor vessel and the three steam generators at the heart of the plant. They were taken out whole. In the case of the reactor vessel, a giant carbon-steel pot with a stainless-steel liner, the "internals"—the metal frame that held the core and channeled the water on its serpentine path—were chopped up with water jets and cutting tools. The work was done by remote control and underwater. (Tellingly, the American reactor industry did not survive the full life cycle of the first big plants; a French company, Framatome ANP, provided the technology for slicing apart the big metal components.)

Then the reactor core was filled with cement, or "grouted" in industry parlance, to reduce the possibility of parts loosening in coming centuries. The vessel was lifted out in preparation for a barge trip to a low-level-waste dump. The environmental benefit to moving the material is that it is easier to guard and monitor in a central location.

The internals will eventually go wherever the fuel—uranium pellets encased in pencil-thin rods—goes. In theory, that will be Yucca Mountain, in Nevada, where the Department of Energy hopes to build a nuclear waste repository. In any case, the internals will wait in four giant steel-and-concrete casks, alongside 60 other casks filled with spent fuel.

These, on a six-acre plot, form the new Independent Spent Fuel Storage Installation. The ISFSI, one of the newer acronyms to enter the nuclear lexicon, is similar to those springing up at plants around the country. Maine Yankee's has earthen berms around the 18-foot-high canisters, an electrified fence, closed-circuit cameras and a solid-looking guard building.

In fact, although the NRC refuses to certify the casks indefinitely, it is not dear what would make them unsafe to use over the next 100 years or more, except global sea-level rise or, perhaps, terrorism. Critics say the casks are vulnerable to attack. Some have suggested sheltering the canisters in the dome. The NRC says it believes the casks are safe.

T HE FUEL IS AN OBVIOUS PROBLEM. Technicians made 14,300 measurements, a little more than half in areas where they did not expect to find contamination. On the other hand, certain parts were barely tested, such as the reactor cooling system, the emergency соте cooling sys tern, and the chemical volume and control system; these were presumed to be dirty. Some sampling was done by running a vehicle over the land at speeds lower than five miles an hour. Many samples were sent to off-site labs for more sensitive analysis than was possible using Geiger-Mueller detectors.

The residual radiation permitted by state and federal regulations was so low that plant managers concluded that they would have to determine what normal background was, lest they end up removing radionuclide that would have been present had the plant never been built (For instance, one major source of background radiation is fallout from atmospheric nuclear tests, mostly cesium 137.) So they sampled for beta activity on painted and unpainted concrete, ceramic rile, and asphalt.

A power reactor makes two kinds of radioactive materials. The dominant type is fission products. As nuclear plants run, they split uranium, which emits so little radiation that technicians handle raw fuel in nothing more than cotton gloves. But uranium splits into a dozen major kinds of fragments, which in turn decay into others. The fragments, and many of the decay products, are highly unstable. They readily give off energy—in the form of a gamma ray, an alpha or beta particle, or sometimes a gamma ray and a particle—to return to equilibrium. The fuel begins as a ceramic pellet wrapped in a metal tube and bathed in ordinary water. But in operation die ceramic fractures; at several plants, including Maine Yankee, the tubing leaked, allowing fission products to enter the cooling water. Many of these radioactive particles "plate out" on the interior of die vessel or on die piping.

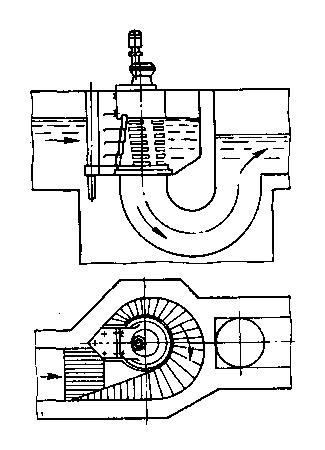

In the pressurized-water design, the water that circulates past the fuel runs through giant heat exchangers, called steam generators, streaming inside thin-walled metal pipes, while clean water on the outside is boiled into steam, which then flow; to the turbine. At Maine Yankee, those cubes leaked, too. And as НШ1 contaminated water was sometimes spilled into drains.

To cope with these fission products, plant technicians washed the piping with chemicals, lowering the radiation in the primary coolant loops fivefold. For surface-contaminated concrete, workers turned to "scabbling," or blasting away the first quarter-to half-inch; dust was vacuumed out and went through a high-efficiency particulate air, or HEP A, filtration system.

Even if the tubes or die fuel had never leaked, there is a second kind of contamination: activation products, atoms that are struck by neutrons from the fissioning uranium, absorb the neutron and become unstable, or radioactive, instead of splitting. Technicians found evidence of activation products up to two feet deep into concrete. Over the years of operation, the reactor internals are generally so transformed by neutron irradiation that they must be treated as high-level waste.

According to the NRC, one of the dominant activation products and a major source of radioactivity aside from the fuel is cobalt 60. It is produced by die interaction of neutrons and cobalt 59 or nickel, both components of various metal alloys. There is a saving grace to cobalt 60: its half-life, or the period that it takes half the material to give off its particles and gamma rays and transmute itself to nonradioactive nickel 60, is just 5.27 years. In theory, workers could simply wait it out; in 21 years, 15/16 of the cobalt 60 would be gone.

WITH NO CENTRAL FACILITY yet available for high-level radioactive mate, rials, commercial nuclear power plants are opening Independent Spent Fuel Storage Installations to house giant casks of their waste. At some plants these steel-and-concrete containers rest horizontally [farright), but at Маше Yankee the casks are upright, under earthen berms, on a six-acre plot.

WORDLIST:

Decommissioning вывод их эксплуатации АЭС

IAEA Международное управление

по ядерной энергии

Plant cleanout очистка(расчистка) станции

decontamination дезактивация

dismantling демонтаж оборудования

demolition снос, обрушение; разборка

shutdown остановка (заглушение) реактора

fuel processing facility установка по переработки топлива

to condition проверять на соответствие требованиям

storage хранение

disposa захоронение

storage pool бассейн хранения отработанного топлива

wash out reagent дезактивирующий реагент

preading contamination источник загрязнения

radiation exposure радиоактивное облучение (незащищенность)

tailing зд. отходы

power pylon опора линии электропередач

open gondola открытый полувагон (америк.)

containment dome купол защитной оболочки

water main магистральный водопровод, водовод

texture cтроение (состав)

water jet водомёт, гидромонитор

nuclear waste repository могильник радиоактивных отходов

cask зд. защитный транспортный контейнер

earthen berm земляная обваловка

canister контейнер

Geiger-Mueller detector счетчик Гейгера

residual radiation остаточная радиация

steam generator парогенератор

primary coolant loop первичный охлаждающий контур

embitterment повышение хрупкости; хрупкость

EXERCISES:

/. Put several questions to the text above and answer them:

a) What is decommissioning process? Please, continue...

//. Translate the following text into Russian:

Adding to the complexity is that each isotope will persist for a different length of time. For example, among the most prevalent at the time of shutdown was cobalt 60, with its five-year half-life. Later, cesium 137, with a half-life of 30.2 years, will be the major concern. Eventually the remaining radioactive sources will be the trace amounts of isotopes that have half-lives in the thousands of years eventually occur— one of the other remaining questions that will influence the fate of aging reactors. The plants were originally licensed for 40 years from the issuance of a construction permit. The building of some dragged on so long that the NRC agreed to move up the start of the clock, to the time when operations actually began. Then it began offering 20-year license extensions. Most of the 103 planes running seem likely to apply.

Still, the economic life of old reactors is uncertain. They resemble older cm, worth an oil change but not a new transmission. Maine Yankee was retired because problems with its wiring and steam generators were becoming obvious. A sister plant, Yankee Rowe in Massachusetts, suffered from embrittlement of its reactor vessel. This condition, caused by years of neutron bombardment, makes the reactor vulnerable to thermal shock—that is, it could crack if the emergency core cooling system dumped in cold water. The extent of embrittlement at Yankee Rowe was not known, but the owners decided that it was not worth the price to find out.

Even those plants with 20-year life extensions will probably not run until the last day of their licenses. Capital improvements required for continued operation in the past few years would have to earn back their cost in a very short period of time.

The exert of decommissioning required is also uncertain. There are less drastic options than a return to green-field status.

III. Translate the following extract into Russian:

Another uncertainty is how much of the debris will require disposal. The NRC announced on November 6, 2002, that it would develop a rule for recycling contaminated metal. Proponents say that slightly radioactive metal would be fine for rebar encased in concrete; others worry that it could turn up in the braces on children's teeth or in pants zippers. When the Energy Department tried to salvage nickel and other metals from its nuclear plants in the mid-1990s, public outrage was so great that the program was ended in 2000.

And the final cost will depend in part on how long the industry waits for permanent disposal of high-level nuclear fuel. Until that is resolved, there will be one large patch of concrete on the Maine coast where snips will not stick; the on-site storage ISFSI casks generate up to 17 kilowatts each, about as much as a dozen handheld hair dryers. They suggest an industrial-age Stonehenge although their builders fervently hope no one will forget what they are for. Filling the cask began last August and will last well into 2003. When that job is finished, workers can tear down the spent fuel pool, the last remaining working system of the old plant.

Throughout the debate about decommissioning in Maine, opponents cut the owners no breaks, requiring, painstaking, expensive process. But the owners have demonstrated that, technologically speaking, this hill is not too high to climb.

IV. To check yourself try to translate thefollowing text at sight: