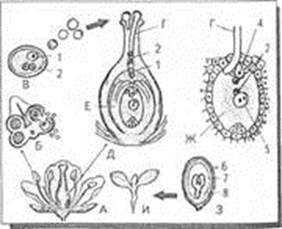

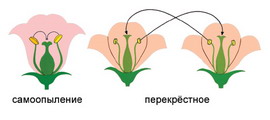

Двойное оплодотворение у цветковых растений: Оплодотворение - это процесс слияния мужской и женской половых клеток с образованием зиготы...

Кормораздатчик мобильный электрифицированный: схема и процесс работы устройства...

Двойное оплодотворение у цветковых растений: Оплодотворение - это процесс слияния мужской и женской половых клеток с образованием зиготы...

Кормораздатчик мобильный электрифицированный: схема и процесс работы устройства...

Топ:

Оценка эффективности инструментов коммуникационной политики: Внешние коммуникации - обмен информацией между организацией и её внешней средой...

Устройство и оснащение процедурного кабинета: Решающая роль в обеспечении правильного лечения пациентов отводится процедурной медсестре...

Когда производится ограждение поезда, остановившегося на перегоне: Во всех случаях немедленно должно быть ограждено место препятствия для движения поездов на смежном пути двухпутного...

Интересное:

Принципы управления денежными потоками: одним из методов контроля за состоянием денежной наличности является...

Отражение на счетах бухгалтерского учета процесса приобретения: Процесс заготовления представляет систему экономических событий, включающих приобретение организацией у поставщиков сырья...

Подходы к решению темы фильма: Существует три основных типа исторического фильма, имеющих между собой много общего...

Дисциплины:

|

из

5.00

|

Заказать работу |

Содержание книги

Поиск на нашем сайте

|

|

|

|

Part I

1. Learn the words:

| annealing | отжиг |

| austenite | аустенит |

| carburization | цементация, науглероживание |

| cementite | цементит, карбид железа |

| ductility | пластичность |

| ferrite | 1) феррит; 2) ферритный, ферритовый |

| hardening | 1) закалка; 2) повышение твердости, твердение |

| heat treatment | термическая обработка |

| martensite | мартенсит |

| normalizing | нормализация |

| pearlite | перлит |

| quench | подвергать закалке, резко охлаждать |

| strength | прочность; предел прочности, временное сопротивление |

| tempering temperature | температура отпуска, температура нагрева при отпуске |

2. Read text A and answer the question: What methods of heat treatment are used to obtain steels with certain mechanical properties for certain needs?

3. In metallurgy, one may encounter many terms that have very specific meanings within the field. Match terms with their definitions:

| 1. | Strength | a. | resistance to fracture. It often increases as strength decreases, because a material that bends is less likely to break. |

| 2. | Hardness | b. | describes a material's tendency to break before bending or deforming either elastically or plastically. Brittleness increases with decreased toughness, but is greatly affected by internal stresses as well. |

| 3. | Toughness | c. | is often used to describe strength or rigidity but, in metallurgy, the term is usually used to describe a surface's resistance to scratching, abrasion, or indentation. In conventional metal alloys, there is a linear relation between indentation hardness and tensile strength, which eases the measurement of the latter. |

| 4. | Brittleness | d. | also called flexibility, this is the ability to deform, bend, compress, or stretch and return to the original shape once the external stress is removed. |

| 5. | Elasticity | e. | also called rigidity, this is resistance to permanent deformation and tearing. |

| 6. | Wear resistance | f. | Usually synonymous with hardness, this is resistance to erosion, ablation, spalling, or galling. |

Identify the part of speech and translate the words.

a) to heat - to reheat - to preheat - to overheat - to underheat; b) to carburize - to recarburize - to decarburize - to overcarburize - to undercarburize; c) hard – harder - to harden – hardened – hardening – hardness – hardenable - hardenability; d) to resist - resistance; e) heat – heater - heating.

Text A.

Heat treatment processes

Hardening involves heating of steel, keeping it at an appropriate temperature until all pearlite is transformed into austenite, and then quenching it rapidly in water or oil. The temperature at which austentizing rapidly takes place depends upon the carbon content in the steel used. The heating time should be increased ensuring that the core will also be fully transformed into austenite. The microstructure of a hardened steel part is ferrite, martensite, or cementite.

Tempering involves heating steel that has been quenched and hardened for an adequate period of time so that the metal can be equilibrated. The hardness and strength obtained depend upon the temperature at which tempering is carried out. Higher temperatures will result into high ductility, but low strength and hardness. Low tempering temperatures will produce low ductility, but high strength and hardness. In practice, appropriate tempering temperatures are selected that will produce the desired level of hardness and strength. This operation is performed on all carbon steels that have been hardened, in order to reduce their brittleness, so that they can be used effectively in desired applications.

Annealing treats steel up to a high temperature, and then cools it very slowly to room temperature, so that the resulting microstructure will possess high ductility and toughness, but low hardness. Annealing is performed by heating a component to the appropriate temperature, soaking it at that temperature, and then shutting off the furnace while the piece is in it. Steel is annealed before being processed by cold forming, to reduce the requirements of load and energy, and to enable the metal to undergo large strains without failure.

Normalizing involves heating steel, and then keeping it at that temperature for a period of time, and then cooling it in air. The resulting microstructure is a mixture of ferrite and cementite which has a higher strength and hardness, but lower ductility. Normalizing is performed on structures and structural components that will be subjected to machining, because it improves the machinability of carbon steels.

Carburization is a heat treatment process in which steel or iron is heated to a temperature, below the melting point, in the presence of a liquid, solid, or gaseous material which decomposes so as to release carbon when heated to the temperature used. The outer case or surface will have higher carbon content than the primary material. When the steel or iron is rapidly cooled by quenching, the higher carbon content on the outer surface becomes hard, while the core remains tough and soft.

Surface Hardening. In many engineering applications, it is necessary to have the surface of the component hard enough to resist wear and erosion, while maintaining ductility and toughness, to withstand impact and shock loading. This can be achieved by local austentitizing and quenching, and diffusion of hardening elements like carbon or nitrogen into the surface. Processes involved for this purpose are known as flame hardening, induction hardening, nitriding and carbonitriding.

5. Read the text and answer the following questions:

1) What heat treatment processes do you know?

2) What does the temperature at which austentizing takes place depend upon?

3) What improves the machinability of carbon steels?

4) Does normalizing involve cooling steel?

5) What is carburization?

6) Why is it necessary in many engineering applications to have the surface of the component hard enough to resist wear and erosion?

6. Complete the sentences:

1) Hardening involves heating of steel …

2) The temperature at which austentizing rapidly takes place depends …

3) Tempering involves heating steel …

4) Higher temperatures will result …

5) Steel is annealed before …

6) Normalizing is performed on structures …

7) Carburization is a heat treatment process …

8) In many engineering applications …

7. Fill in the correct word from the list: brittle, heat treatment, heated, reheating, tempering, quenching, ductile, tempering temperatures

1) _____ is a heat treatment when metal at a high temperature is rapidly cooled by immersion in water or oil. Quenching makes steel harder and more brittle, with small grains structure. 2) ____ is a heat treatment applied to steel and certain alloys. Hardened steel after quenching from a high temperature is too hard and 3) _____ for many applications. Tempering, that is 4) _____ to an intermediate temperature and cooling slowly, reduces this hardness and brittleness. 5) ______ depend on the composition of the steel but are frequently between 100 and 650 °C. Higher temperatures usually give a softer, tougher product. The color of the oxide film produced on the surface of the 6) _____ metal often serves as the indicator of its temperature. Annealing is a 7) _____ in which a material at high temperature is cooled slowly. After cooling the metal again becomes malleable and 8) ____ (capable of being bent many times without cracking). All these methods of steel heat treatment are used to obtain steels with certain mechanical properties for certain needs.

|

|

|

Семя – орган полового размножения и расселения растений: наружи у семян имеется плотный покров – кожура...

Биохимия спиртового брожения: Основу технологии получения пива составляет спиртовое брожение, - при котором сахар превращается...

Поперечные профили набережных и береговой полосы: На городских территориях берегоукрепление проектируют с учетом технических и экономических требований, но особое значение придают эстетическим...

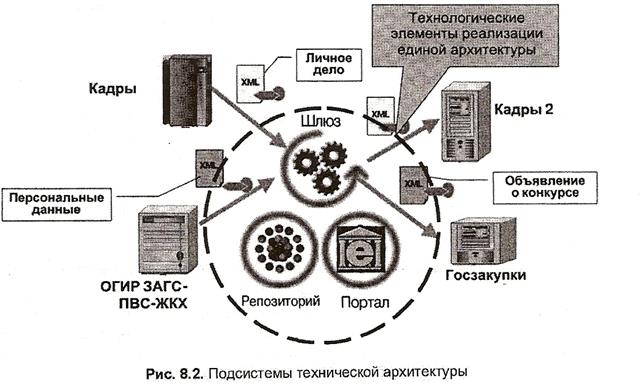

Архитектура электронного правительства: Единая архитектура – это методологический подход при создании системы управления государства, который строится...

© cyberpedia.su 2017-2026 - Не является автором материалов. Исключительное право сохранено за автором текста.

Если вы не хотите, чтобы данный материал был у нас на сайте, перейдите по ссылке: Нарушение авторских прав. Мы поможем в написании вашей работы!