Наброски и зарисовки растений, плодов, цветов: Освоить конструктивное построение структуры дерева через зарисовки отдельных деревьев, группы деревьев...

Кормораздатчик мобильный электрифицированный: схема и процесс работы устройства...

Наброски и зарисовки растений, плодов, цветов: Освоить конструктивное построение структуры дерева через зарисовки отдельных деревьев, группы деревьев...

Кормораздатчик мобильный электрифицированный: схема и процесс работы устройства...

Топ:

Эволюция кровеносной системы позвоночных животных: Биологическая эволюция – необратимый процесс исторического развития живой природы...

Определение места расположения распределительного центра: Фирма реализует продукцию на рынках сбыта и имеет постоянных поставщиков в разных регионах. Увеличение объема продаж...

Установка замедленного коксования: Чем выше температура и ниже давление, тем место разрыва углеродной цепи всё больше смещается к её концу и значительно возрастает...

Интересное:

Берегоукрепление оползневых склонов: На прибрежных склонах основной причиной развития оползневых процессов является подмыв водами рек естественных склонов...

Средства для ингаляционного наркоза: Наркоз наступает в результате вдыхания (ингаляции) средств, которое осуществляют или с помощью маски...

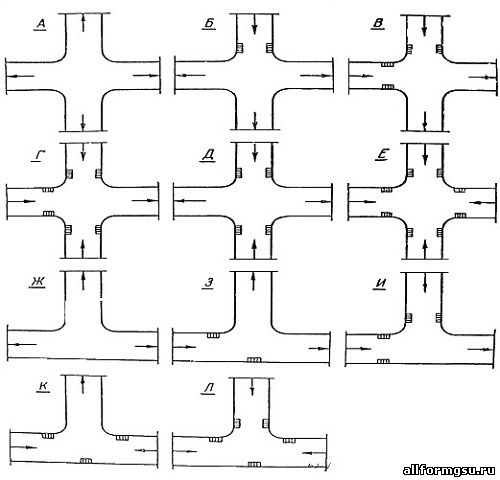

Искусственное повышение поверхности территории: Варианты искусственного повышения поверхности территории необходимо выбирать на основе анализа следующих характеристик защищаемой территории...

Дисциплины:

|

из

5.00

|

Заказать работу |

|

|

|

|

Exercise 1. Read and learn the following words and expressions:

Vocabulary notes:

1. сylinder head – крышка цилиндра

2. welding – сварка

3. oxyacetylene – кислородоэтиленовый

4. contraction stress – напряжение при сжатии

5. studding – соединение

6. crank shaft – коленчатый вал

7. hazard – препятствие

8. refinishing – повторная отделка

9. alignment – установка

10. torsional vibration – вибрация вращения

11. flexible – гибкий

12. bearing box – корпус подшипника

13. crosshead – поперечина

14. circumferential crack – кольцевая трещина

15. piston – поршень

16. substantially – значительно

17. salvage – спасти

18. valve gear – клапанный механизм

Exercise 2. Read, translate and discuss the text.

Head repairs

The head is usually the most complicated casting on the engine, and as such suffers most from heat troubles. The usual head repair is welding of cracks. Both oxyacetylene and electric welding are used, but the former is preferred if the location of the crack will permit its use. If the crack is near the outer edge of the head, where expansion and contraction stresses can be accommodated, gas welding can be used, but if the crack is near the center of the head or surrounded by unsymmetrical masses of metal, as is usually the case, electric welding must be resorted to. To make a successful head repair, electric welding must be done very skillfully and studding employed.

Crank shafts

Breakage of crank shafts in years gone by was accepted as one of the hazards inherent in Diesel-engine operation, but at the present time such breakage is very unusual. Most repair work on crank shafts consists of refinishing pins and bearings that have become scored or worn, or connecting alignment of the shaft in its bearings. Whenever it is necessary to renew a broken shaft, it is found that breakage is due to misalignment of torsional vibration. Wear of main bearings is more rapid in marine engines than in land engines. The more flexible nature of the structure on which the engine rests, as compared to the mass of concrete under the land engine, makes it more difficult to maintain a continuously unbroken oil film between shaft and bearing box.

Torsional vibration is sufficiently well understood that its occurrence can be predicted with accuracy in new engines and steps taken to eliminate it. It is a much less common sourse of trouble than in former years, but it is found occasionally.

Connecting rods and crossheads

Connecting rods repairs are so infrequently required that they may be dismissed without discussion. Crosshead trouble is normally confined to slipper wear.

Piston rods

Piston-rod troubles may be said to be non-existent in single-acting engines that have such rods, but in double-acting engines that have such rods, but in double-acting designs piston-rod breakage has been rather common.

|

|

Pistons

From the repairman’s point of view, the piston seems to be the most troublesome of all the major parts of the Diesel engine. The trouble encountered is usually cracking, or wear of ring slots. There are two ways in which cracking occurs: approximately radial cracks develop in the crown or circumferential cracks in the side or skirt. The first is the most common kind, and the appearance of the cracks indicates that is associated with the phenomenon of metal growth by repeated heating. The second type of fracture, cracks in the side, is almost invariably due to piston seizure in the liner and is usually associated with cooling-system failure. Welding procedure has been developed to the point where most cracked pistons can be salvaged at a cost substantially less than the price of a new one.

Valves and valve gear

Under this heading there is comparatively little to be recorded. The exhaust valve is the one most frequently in need of repair, due to the fact that a leak usually results in a burned-out valve ore seat.

Exercise 3. Answer the following questions.

1. What is the most complicated casting on the engine?

2. What is the usual head repair?

3. Why was breakage of crank shafts accepted as one of the hazards inherent in Diesel engine operation?

4. What does most repair work on crank shafts consist of?

5. Why is torsional vibration much less common source of trouble now than in former years?

6. What is crosshead trouble normally confined to?

7. In what engines may piston-rod troubles be said to be nonexistent?

8. From whose point of view does the piston seem to be the most troublesome of all the major parts of the Diesel engine?

9. What repair does the exhaust valve frequently require?

|

|

|

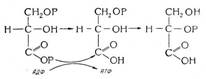

Биохимия спиртового брожения: Основу технологии получения пива составляет спиртовое брожение, - при котором сахар превращается...

Поперечные профили набережных и береговой полосы: На городских территориях берегоукрепление проектируют с учетом технических и экономических требований, но особое значение придают эстетическим...

Организация стока поверхностных вод: Наибольшее количество влаги на земном шаре испаряется с поверхности морей и океанов (88‰)...

Своеобразие русской архитектуры: Основной материал – дерево – быстрота постройки, но недолговечность и необходимость деления...

© cyberpedia.su 2017-2024 - Не является автором материалов. Исключительное право сохранено за автором текста.

Если вы не хотите, чтобы данный материал был у нас на сайте, перейдите по ссылке: Нарушение авторских прав. Мы поможем в написании вашей работы!