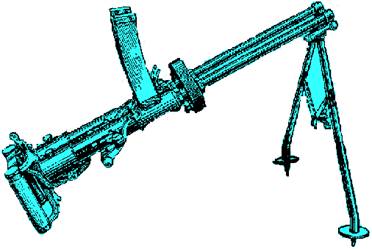

Кормораздатчик мобильный электрифицированный: схема и процесс работы устройства...

Историки об Елизавете Петровне: Елизавета попала между двумя встречными культурными течениями, воспитывалась среди новых европейских веяний и преданий...

Кормораздатчик мобильный электрифицированный: схема и процесс работы устройства...

Историки об Елизавете Петровне: Елизавета попала между двумя встречными культурными течениями, воспитывалась среди новых европейских веяний и преданий...

Топ:

Методика измерений сопротивления растеканию тока анодного заземления: Анодный заземлитель (анод) – проводник, погруженный в электролитическую среду (грунт, раствор электролита) и подключенный к положительному...

Проблема типологии научных революций: Глобальные научные революции и типы научной рациональности...

Интересное:

Финансовый рынок и его значение в управлении денежными потоками на современном этапе: любому предприятию для расширения производства и увеличения прибыли нужны...

Мероприятия для защиты от морозного пучения грунтов: Инженерная защита от морозного (криогенного) пучения грунтов необходима для легких малоэтажных зданий и других сооружений...

Национальное богатство страны и его составляющие: для оценки элементов национального богатства используются...

Дисциплины:

|

из

5.00

|

Заказать работу |

|

|

|

|

| To refer to people | To refer to things | |

| Subject | who, that | which, that |

| Object | (who, that whom) | (which, that) |

| Possessive | whose | whose |

| To refer to people | To refer to things | |

| Subject | who | which |

| Object | who,whom | which |

| Possessive | whose | whose |

.

10. Look at the following sentences and decide whether they have got defining (D) or non-defining (N) relative clauses:

1. The design that we selected was in factthe most expensive.

2. Albrecht Durer, who was one of the first artists of the 1500s, used intaglio printing with highly polished copper plates.

3. The new investment plan, which was announced on Wednesday, will take five years to complete.

4. The manager who made the mistake lost his job.

5. The rotogravure printing department is the one whose contribution has been the most significant this year.

Write down 10 sentences of your own with the relative clauses.

Unit FIVE

TEXT 1

LETTERPRESS

Letterpress (relief) printing, of which traditional letterpress and flexography form a part, is the oldest printing technology. Printing is done by means of raised printing elements. Letterpress printing is a mechanical technology in which a relatively high pressure is required to transfer the highly viscous, pasty ink to the paper via the hard printing elements. For centuries letterpress printingwith rigid printing plates, made from alloys of lead, tin and antimony, was the dominant printing technology.

Letterpress printing was the predominant book-printing process. For four centuries it was also the predominant printing technology for posters, announcements, printed matter for churches, government and businesses, single- or two-page local news-sheets, and daily newspapers.

In the chronology of their development, presses and machinery are subdivided into hand presses and platens, high-speed presses and web presses, on the basis of the different pressing methods involved.

Platen (or clam-shell) presses are the oldest type and are used for small printing jobs. They consist of a flat bed on which the image (type or plates) are laid and another flat surface, the platen, which is connected to a screw or lever. Paper is laid on the bed and pressed by the platen to transfer the image to the surface.

Sheetfed flatbed presses feature a cylinder, on which the paper is attached, that rolls over the bed of inked type. This design overcame the problem of uneven impression on the paper surface that often occurred in platen presses.

|

|

In rotary webfed presses a continuous roll of paper is fed between two cylinders, the plate cylinder and the impression cylinder. The plate cylinder, either electrotype or stereotype, is automatically inked and pressed against the paper as it unrolls. After the paper is printed, it can be cut into individual sheets and folded. Flatbed and rotary presses can be designed to print on both sides of the paper simultaneously (perfecting) and to reproduce colour illustration.

Рис. 3

In addition to these three types the belt press is used for continuous inline operations of printing and finishing. It can print, collate and bind a complete book in one pass through the press. When a roll of paper is fed, it comes in contact with the first belt which prints all the pages for one side, after the ink drying the paper turned over, and come in contact with the second belt, dried, slit into ribbons, folded, cut into signatures, collated into books and adhesive-bound into preprinted covers.

A common feature of all letterpress processesis the fact that the printing elements of the plate are raised above the nonprinting elements. The printing elements that are at the same height (image areas) are coated with a layer of ink of constant thickness by the application rollers. This is followed by the transfer of the ink to the substrate.

Letterpress is still used to print forms, labels, lottery tickets, security papers, telephone books, and paperbacks, though there is a downward trend. Letterpress was also used for newspaper web printing. A few newspaper rotaries are still used both for direct and indirect printing (letterset, with blanket cylinder). The last newspaper letterpress printing presses were delivered in the 1980s.

The most prevalent printing plate is the wash-off printing plate. There are very different wash-off systems and wash-off depths available in conjunction with different bases. The production process is described using the example of “Nyloprint” printing plates (from BASF).

The following operational steps are necessary to make the Nyloprint plate:

The fundamental disadvantages of letterpress printing compared to offset printing are the expensive printing plate, the costly makeready of the printing plate, the limited print quality and the limit of production speed.

ESSENTIAL VOCABULARY

Words and Word Combinations

ACTIVITIES

|

|

|

Организация стока поверхностных вод: Наибольшее количество влаги на земном шаре испаряется с поверхности морей и океанов (88‰)...

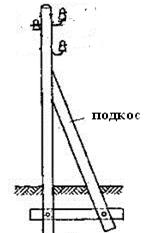

Опора деревянной одностоечной и способы укрепление угловых опор: Опоры ВЛ - конструкции, предназначенные для поддерживания проводов на необходимой высоте над землей, водой...

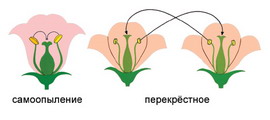

Семя – орган полового размножения и расселения растений: наружи у семян имеется плотный покров – кожура...

История развития пистолетов-пулеметов: Предпосылкой для возникновения пистолетов-пулеметов послужила давняя тенденция тяготения винтовок...

© cyberpedia.su 2017-2024 - Не является автором материалов. Исключительное право сохранено за автором текста.

Если вы не хотите, чтобы данный материал был у нас на сайте, перейдите по ссылке: Нарушение авторских прав. Мы поможем в написании вашей работы!