SSOM grade coal and composite binder based on coal tar and wood-chemical resins were used as the initial raw material. Raw material characteristics obtained by atomic emission spectroscopy with inductively bound plasma (AES-ICP) and viscometry are presented in Table 1.

Table 1. Raw material characteristics for obtaining GAC samples

| Coal

| Binder

|

| Ash content 3,7% (mass.)

| Coke 16,5% (mass.)

|

| Volatile compound content 18,5% (mass.)

| Viscosity at 40о С – 0,96 Pa·s

60о С – 0,259 Pa·s

|

Preparation of raw material involved the production of coal dust with different fractional composition. For this purpose, the raw coal was ground in a ball mill for different time periods from 1 to 4 hours (samples SS-1, SS-2, SS-3, SS-4), with subsequent screening of the resulting dust. The basic fraction content in the dust samples was the same after grinding coal for 2 and 3 hours, so the samples were used for further studies, with a grinding time of 1, 3 and 4 hours. The samples of activated carbons were obtained according to the technology described above.

Study of the porous structure of activated carbons

The specific surface area, size and pore volume of activated carbon samples and absorbers based on them were determined in a fast gas sorption analyzer "NOVA-1200 e".

The sample of the substance under study was preliminarily degassed by heating and blowing in a dynamic gas flow. After degassing, a small amount of adsorbate gas was added to the sample cell, whose molecules were adsorbed on the sample surface forming a monolayer. The amount of adsorbed nitrogen was determined by the change in adsorbate pressure.

Determining the true and envelope density

The true density of the sorbent was determined using a Quantachrome Ultrapycnometer 1200e gas pycnometer. The technique for measuring true density was based on the use of Archimedes' law and Boyle-Mariott's law to determine the volume. To secure maximum accuracy, inert gas was used as the displaced liquid, which had a very high degree of permeability. When measuring the volume of the analyzed sample, inert gas was displaced by the analyzed sample from the measuring chamber into the additional one. The volume of the displaced gas equal to the volume of the analyzed sample introduced into the measuring chamber was estimated by the change in the pressure sensor readings with the additional chamber being opened. When performing the analysis, it was possible to use measuring cells of different volumes.

The sorbent envelope density was determined using a GeoPyc1360 pycnometer. To measure the envelope density of a sample on the GeoPyc 1360 analyzer, its total volume was first determined. For this purpose, quasi-liquid medium (powdery material with high fluidity) DryFlo was placed in the chamber and the volume of this medium was measured (blank measurement). Then the sample was placed in the chamber with the medium and its volume was measured.

Results

The fractional composition of coal dust and coal-resin composition serving as a basis for the production of GAC samples are presented in table 2.

Table 2. Fractional composition of coal dust and coal-resin composition

|

|

| Particle content, %

|

|

| SS-1

| SS-3

| SS-4

| Binder

|

| Particle size, µm

| 0,1-40

|

| 79,54

| 88,64

| 95,68

| -

|

| 40-63

|

| 8,60

| 6,53

| 3,26

| -

|

| 63-100

|

| 6,52

| 3,86

| 1,06

| -

|

| 100-2000

|

| 5,35

| 0,97

| 0,00

| -

|

| Coal-resin composition, %

|

| 73,0

| -

| -

| 27,0

|

|

| -

| 70,5

| -

| 29,5

|

|

| -

| -

| 70,0

| 30,0

|

As the degree of coal grinding increases, the number of binders needed to produce paste increases too, resulting in an increase in the mass fraction of volatile substances in granules.

Table 3 shows the characteristics of GAC samples obtained using coal dust with different particle sizes.

Table 3 - Characteristics of finished activated carbons.

| Indicators

| Sample

|

| SS-1

| SS-3

| SS-4

|

| True density, g/cm3

| 2,089

| 2,091

| 2,132

|

| Envelope density, g/cm3

| 0,753

| 0,614

| 0,726

|

| BET specific surface area, m2/g

| 1065

| 1142

| 1166

|

| Total pore volume, cm3/g

| 0,503

| 0,529

| 0,524

|

| Dubinin-Radushkevich method of micropore volume, cm3/g

| 0,434

| 0,465

| 0,478

|

| Dubinin-Radushkevich method of half-pore width, nm

| 0,74

| 0,75

| 0,80

|

As can be seen from Table 3, all activated coal samples comply with their specifications [4]. The results also show that the increased proportion of fine particles (0.1–40 µm) in coal dust makes it possible to increase the sorption capacity of the obtained granular activated carbons and contributes to the development of their porous structure. At the same time the volume of micropores increased, but their size increased slightly.

Conclusion

The study revealed the impact of carbon-containing dust granulometric composition on GAC quality.

Optimal coal-resin compositions were determined for different degrees of grinding carbon-containing raw materials.

It was also found that increasing the proportion of coal dust fine fraction in the coal-resin composition we can promote the development of GAC porous structure and increase its sorption capacity. The results obtained can be further used for the production of GAC with the specified characteristics.

Reference list

1. Мухин, В. М. Производство и применение углеродных адсорбентов : учебное пособие / В. М. Мухин, В. Н. Клушин. – Москва : Российский химико-технологический университет им. Д. И. Менделеева, 2011. – 305 с. – ISBN 978-5-7237-0905-8.

2. Мухин, В. М. Активные угли как важный фактор развития экономики и решения экологических проблем // Химия в интересах устойчивого развития. 2016. № 24. С. 309–316.

3. Фарберова, Е. А. Технология получения активных углей и их применение : учебное пособие / Е. А. Фарберова, Е. А. Тиньгаева, А. Р. Кобелева. – Пермь: Издательство Пермского национального исследовательского политехнического университета, 2018. – 147 с. : ил., табл. – ISBN 978-5-398-02018-2.

4. ГОСТ 20464-75. Уголь активный АГ-3. Технические условия : утвержден и введен в действие Постановлением Государственного комитета стандартов Совета Министров СССР от 30 января 1975 г. № 278 : дата введения 1975-03-01 / разработан и внесен Министерством химической промышленности СССР. – Москва : Издательство стандартов, 1999. – 11 с.

| Veronika Pugina

| Вероника Пугина

|

| Perm National Research Polytechnic University

| Пермский Национальный Исследовательский Политехнический Университет

|

| Criteria for the selection of groups of polymer waste for use as a raw component in the production of asphalt concrete

| Критерии отбора групп полимерных отходов для использования в качестве сырья при производстве асфальтобетона

|

| Abstract: The main characteristics and physical and chemical properties of polymer waste are presented. To assess the possibility of using technologies for the disposal of polymer waste, it is proposed to use organizational, technological, environmental, economic criteria. The proposed evaluation criteria made it possible to select HDPE and LDPE waste for use in asphalt concrete, since their chemical composition does not contain hazardous chemical compounds. The technology of recycling polymer waste in asphalt concrete production technologies makes it possible to use the material resource of waste, does not require expensive equipment for preliminary waste preparation, and makes it possible to involve large volumes of waste. The proposed use of the criteria for the assessment of polymer waste helps to determine at an early stage of the development of the recycling technology the boundary conditions of technological impact, which make it possible to use the material resource of waste without forming a technogenic impact on the environment.

| Аннотация: Представлены основные характеристики и физические и химические свойства полимерных отходов. Для оценки возможности использования технологий удаления полимерных отходов предлагается использовать организационные, технологические, экологические, экономические критерии. Предложенные критерии оценки позволили отобрать отходы HDPE и LDPE для использования в асфальтобетоне, поскольку их химический состав не содержит опасных химических соединений. Технология утилизации отходов полимеров в технологиях производства асфальтобетона позволяет использовать материальные ресурсы отходов, не требует дорогостоящего оборудования для предварительной подготовки отходов и позволяет привлекать большие объемы отходов. Разумное использование критериев оценки полимерных отходов помогают определять на раннем этапе разработки технологии рециркуляции пограничных условий технологического воздействия, которое позволяют использовать материальные ресурсы отходов без техногенного воздействия на окружающую среду.

|

Keywords: polymer waste, asphalt concrete, environmental protection, disposal.

Introduction

To date, global production of plastic products has increased from 322 million tonnes in 2015 to 348 million tonnes in 2017. Taking into account the estimated global population growth rates, as well as the current consumption of plastic products, the production of plastics is projected will double by 2025, and more than triple by 2050 [1] The projected dynamics of plastics production in the world, for a visual representation, is shown in Fig. 1. According to various sources, only 15 to 25% of this waste is recycled.

Figure 1 Forecasted dynamics of plastics production in the world.

Polymers are highly resistant to the environment and aggressive chemical environments. In this regard, the generally accepted practice of disposing of polymer products that have completed their service life is ineffective. Direct destruction of polymers by burning them leads to the formation and emission of chemical compounds hazardous to the environment and humans, such as dioxins, furans, mercury and polychlorinated biphenyls, halogens, etc. allow to involve their material and energy potential in the resource cycle of obtaining target products. At present, a sufficient number of technologies have been developed that allow considering polymer waste as a full-fledged raw material. [2-5] The achieved effects of saving primary resources and reducing the accumulated polymer waste do not correlate with the possible secondary pollution of the environment during the implementation of the recycling technology. At present, insufficient attention is paid to the formation of a secondary technogenic impact on the geospheric envelopes of the Earth during the implementation of utilization technologies. When using these technologies, physical and chemical effects on waste, the use of high temperatures are possible. At the same time, new chemical compounds can be formed that can harm the environment. In this regard, it is necessary to establish criteria that will ensure the safe use of the resource potential of polymer waste in technologies for obtaining target products in demand on the market.

Materials and Method

The analysis of scientific research by foreign scientists and the Russian Federation showed that in order to ensure environmental safety and when implementing the technology, it is necessary to take into account such properties of polymers as the melting point, chemical composition, as well as the ability to form chemical compounds that are hazardous to the environment during technological disposal operations. The main groups of polymers used in construction and housing and communal services and their physicochemical properties are presented in table 1.

Table 1 Physicochemical properties of various groups of polymers

| Polymer groups

| PET

| HDPE

| PVC

| LDPE

| PP

| PS

|

| Chemical formula

| (C10H8O4)n

| (С2H4)n

| (C2H3Cl)n

| (С2H4)n

| (C3H6)n

| (C8H8)n

|

| Melting temperature, °C

| 260

| 129-135

| 150-220

| 125-132

| 160-170

| 240

|

| Density, g/cm3

| 1,33-1,42

| 0,93-0,97

| 1,34-1,34

| 0,90-0,93

| 0,90-0,92

| 1,05

|

| Tensile strength, MPa

| 172

| 18-32

| 40-60

| 7-16

| 245-392

| 39,2-44

|

| Danger to the environment

| Releases phthalate and heavy metals

| Non-toxic

| Very toxic

| Non-toxic

| Non-toxic

| Releases styrene

|

For the successful implementation of the technology of recycling polymer waste, it is proposed to use: organizational and technological, environmental, economic criteria. The criteria assess the technological feasibility of using polymer waste, the risks of the formation of chemical compounds hazardous to the environment and humans, and the economic attractiveness of the technology.

The organizational and technological criterion assesses: the possibility of collecting and the need for sorting polymer waste; the volume of waste generation and the volume of previously accumulated; the need and possibility of preliminary processing of polymer waste (the need for crushing, washing, sorting); physical parameters of the recycling process. Environmental friendliness makes it possible to assess the risks of negative impact on the environment during technological processes of disposal of polymer waste, which are determined by the presence of hazardous chemical compounds in the composition of polymers, the ability to penetrate into the links of the food chain of living organisms. Efficiency determines the financial availability and material benefits in the implementation of technology for the recycling of polymer waste.

In order to test the performance of the above criteria at the Department of Environmental Protection, studies were carried out on the possibility of using waste polymers used in construction and housing and communal services in the production of building materials. One of the promising areas for the disposal of polymers is their use in the composition of asphalt concrete, since bitumen and polymers have the same raw material base in their primary production.

The asphalt concrete production technology has a number of critical technological limitations. In particular, the maximum heating of the mixture should be no more than 190-200 ° C, this is due to the rapid aging of bitumen with increasing temperature. For polymers, a critical indicator is the presence of high temperatures in the recycling process chain, since it is the temperature increase that promotes the formation of new chemically hazardous compounds.

Evaluation of the possibility of using waste polymers in the composition of asphalt concrete using the proposed evaluation criteria is presented in table 2.

Table 2 Evaluation of waste polymers for use in asphalt concrete

| Polymer groups

| PET

| HDPE

| PVC

| LDPE

| PP

| PS

|

| Organizational and technological

| no

| +

| +

| +

| +/-

| no

|

| Environmental friendliness

| no

| +

| no

| +

| +

| no

|

| Profitability

| no

| +

| +/-

| +

| +

| no

|

According to the proposed methodology for assessing polymer waste for their inclusion in the technological schemes for the production of asphalt concrete, the most suitable are HDPE and LDPE waste. The chemical composition does not contain hazardous chemical compounds. The used temperature regimes for the preparation of asphalt concrete make it possible to transfer the waste into a liquid phase, which is necessary for uniform mixing with the bitumen and the mineral base of the asphalt concrete mixture. The temperature range for the preparation of asphalt concrete will not provoke the formation of new chemical compounds hazardous to the environment and humans. The ability to replace part of the bitumen, to obtain asphalt concrete with increased performance indicators, increased service life shows the cost-effectiveness of using these groups of polymer waste in asphalt concrete production technologies.

Result and discussion

To confirm the efficiency of using LDPE waste, laboratory studies of asphalt concrete compositions were carried out using LDPE waste. They showed that when using LDPE it is possible to obtain asphalt concrete in its characteristics that are not inferior to asphalt concrete based on natural raw materials. Indicators of the obtained samples as ultimate strength in compression, shear resistance have better values in comparison with control samples. This indicates improved performance of the pavement, increased service life of the asphalt concrete pavement.

The technology of recycling polymer waste in asphalt concrete production technologies makes it possible to use the material resource of waste, does not require expensive equipment for preliminary waste preparation, and makes it possible to involve large volumes of waste. The recycling technology can be recognized as biopositive and climate neutral, since it does not require special training (with separate waste collection), additional individual heating.

Conclusion

The proposed use of the criteria for the assessment of polymer waste allows at an early stage of the development of recycling technology to determine the boundary conditions of technological impact, which make it possible to use the material resource of waste without forming a technogenic impact on the environment during its implementation.

Reference list

1. Потапова, Е. В. Проблема утилизации пластиковых отходов / Потапова Е.В. // Известия Байкальского государственного университета. 2018. № 4. С. 535–544.

2. Tyuryukhanov, K. Y. Аn impact of waste foundry sand on asphalt concrete mixture / K. Y. Tyuryukhanov, K. G. Pugin. – Text : electronic // Iop conference series: Materials Science and Engineering : сollection of works International Science and Technology Conference «FarEastCon-2019». – URL: https://elibrary.ru/item.asp?id=43260010 (date accessed: 20.03.2021). – Access mode: for registered users of the electronic library «eLibrary.Ru».

3. Пугин, К. Г. Использование отходов металлургии в асфальтобетонах / Г. К. Пугин // Строительные материалы. 2011. № 10. С. 26–30.

4. Тюрюханов, К. Ю. Исследование взаимодействия битума с минеральными частицами в асфальтобетоне / К. Ю. Тюрюханов, К. Г. Пугин // Транспортные сооружения. 2018. Т. 5, № 1. С. 19.

5. Пугин, К. Г. Разработка технологии использования отходов пластика в дорожном строительстве / К. Г. Пугин, В. К. Пугина // Транспорт. Транспортные сооружения. Экология. 2020. № 3. С. 21–28.

| Igor’Russkikh

| Игорь Русских

|

| Perm National Research Polytechnic University

| Пермский Национальный Исследовательский Политехнический Университет

|

| The influence of heat treatment on the structure and properties of low carbon martensitic steel Cr-Mn-Ni-Mo-V-Nb

| Влияние термообработки на структуру и свойства низкоуглеродистой мартенситной стали Cr - Mn - Ni - Mo - V - Nb

|

| Abstract: In this work the author describes the change of low carbon martensitic steel structure and properties depending on the heat treatment. The author describes the reduction of the low carbon steel 08CrG2NMVB impact strength in conditions of high-temperature tempering.

| Аннотация: В этой работе автор описывает изменение структуры и свойств мартенситностической стали с низким содержанием углерода в зависимости от термической обработки. Автор описывает снижение ударной силы низкоуглеродистой стали 08CrG2NMVB в условиях высокотемпературного закаливания.

|

Introduction

With the development of engineering the enhancement of products operating efficiency and as a result their strength properties improvement has become the priority task. Strength improvement of steel in combination with high viscosity and plasticity characteristics makes it possible to reduce the mass of products [1]. Properties of steels and alloys depend directly on heat treatment conditions. Therefore, the purpose of this research is to determine the optimal heat treatment conditions for low carbon martensitic steel 08Cr2G2NMVB.

Materials and Methods

08CrG2NMVB steel billets were in the state after natural air cooling from a hot deformation temperature of at least 900 ° C. The heating of the samples occurred in the chamber laboratory furnaces by two modes:

1) quenching (950 ± 10) ° С, air + tempering (650 ± 10) ° С, 2 hours, air + quenching (950 ± 10) ° С, air, + tempering (650 ± 10) ° С, 2 hours, air + quenching (900 ± 10) ° С, air, cold -70, 2 h + tempering (480 ± 10) ° С, 2 hours, air;

2) quenching (980 ± 10) ° C, air + tempering (250 ± 10) ° C, 2 hours, air;

The resulting microstructure was studied using an OLIMPUS GX-51 microscope with the increase from 500х to 1000х. To identify the microstructure the surface of the grind was etched by 4% H2No3 solution. The measurement of the solidness of the samples the diameter and the height of which was 4 and 3 mm respectively were performed by the TC-2M (Rockwell) device on the HRC scale according to GOST 9013-59. The confidence interval was ± 2 units. The test of samples for the uniaxial stretching was carried out by the INSTRON5969 machine in accordance with GOST 1497-84. According to GOST 9454-78 the impact strength was determined by the impact pendulum IO 5003-0.3 on the samples (the original sample size of 10 × 10 mm) with V-shaped sample cut. The chemical composition of the studied low carbon martensitic steel is presented in Table 1;

Table 1. Mass fraction of elements, % weight. Steel 08Сr2G2NMVB

| С

| i

| n

| r

| o

| i

| V

| b

| S

| P

| u

|

| No more

|

| 0,1

| 1,01

| 1,63

| 2,62

| 0,28

| 0,91

| 0,12

| 0,1

| 0,009

| 0,012

| 0,10

|

Results and Discussion

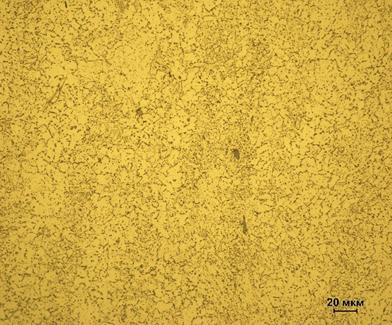

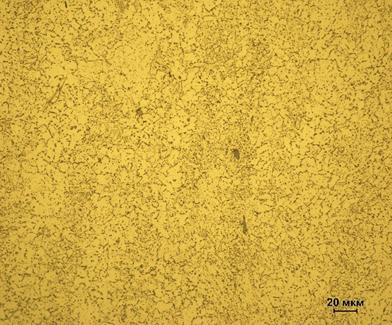

The fine-grained structure of low carbon martensitic steel 08Cr2G2NMBB is specified by the content in the chemical composition of strong carbide-forming elements,such as vanadium and niobium. Figure 1 shows the structure of the studied steel in the state of delivery.

Figure 1. Microstructure of steel 08Cr2G2NMVB in the resignation of delivery

After conducting two modes of heat treatment it was determined austenitic grain score.

|

A

|

| Number of measurements

| 24

| | Minimum size, μm

| 2.3

| | Minimum size, μm

| 10.9

| | Middle size, μm

| 5.2

| |  | Distribution of grain size

| |

|

|

B

|

| Number of measurements

| 29

| | Minimum size, μm

| 3.4

| | Minimum size, μm

| 9.7

| | Middle size, μm

| 6.4

|

| | Distribution of grain size

| |

|

C

C

|

| Number of measurements

| 30

| | Minimum size, μm

| 2.0

| | Minimum size, μm

| 12.9

| | Middle size, μm

| 7.2

|

| | Distribution of grain size

| |

|

D

D

|

| Number of measurements

| 23

| | Minimum size, μm

| 4.3

| | Minimum size, μm

| 10.4

| | Middle size, μm

| 7.0

|

| | Distribution of grain size

| |

|

Figure 2. Microstructure of steel 08x2g2NMFB after heat treatment

A-B - according to the first mode of operation; C-D - according to the second mode of operation.

The results of investigation presented in Figure 2 showed that after cyclic heat treatment of the studied low carbon martensitic steel (LCMS) the average size of austenitic grain reduced to 5-6 microns. The second heat treatment mode which includes a low-temperature tempering, increased the average grain size of austenite to 7 microns. The dissolution of carbides in the austenite leads to its saturation by carbon and carbide-forming elements. In addition to higher tempering stability of LCMS with additives of chromium, vanadium, niobium and titanium carbides dissolving containing these elements occurs at high heating temperature [3]. Presumably carbide dissolving according to the second heat treatment regime was not sufficient to limit grain growth. When low carbon steels are cooled it occurs the intermediate transformation at temperatures below 500o which is followed by the diffusion redistribution of carbon. In [4] the possibility of increasing Mn point followed by γ-α-transformation by separating austenite into the areas with different carbon content.

The mechanical properties of samples of low-gluing martensitic steel 08Cr2G2NMVB, obtained at various thermal processing modes are presented in Table 2.

Table 2. Evaluation of the level of mechanical properties

| Modes

| Heat treatment parameters

| Hardness, HRC

| Mechanical properties

|

| в

| ,2

| δ

| Ψ

| КСV

ГОСТ 9454-78

| |

| kgf/mm2

| %

| J/cm

|

| Mode I

| quenching (950 ± 10) ° С, air + tempering (650 ± 10) ° С, 2 hours, air + quenching (950 ± 10) ° С, air, + tempering (650 ± 10) ° С, 2 hours , air + quenching (900 ± 10) ° С, air, cold -70, 2 h + tempering (480 ± 10) ° С, 2 hours, air;

| 34

| 117

| 91

| 18

| 63

|

490

| |

| Mode II

| quenching (980 ± 10) ° C, air + tempering (250 ± 10) ° C, 2 hours, air;

| 35

| 17

| 7

| 19

| 65

|

1230

| |

After the first mode cyclic heat treatment the reduction of KCV impact strength can be observed. It is amounted to 490 J / cm and is 2.5 times lower than according to the second mode. This is due to the tempering fragility of the first kind in the temperature range of 500-550 ° C. In the process of high-temperature tempering the formation and selection of dispersed inclusions - carbides occurs. The tempering fragility of the first kind is associated with an increase in the share of intercrystalline failure [4]. The carbide theory of brittle behavior is confirmed by the investigation of the alloying elements effects. In studies concerning the tempering brittleness of steels [5] the process of silicon and aluminium alloyage is described in detail, as well as the displacement of the impact strength dip to 400-450 ° C and as a result the suppression of the process of replacing ε-carbide with cementite. In other parameters of mechanical properties with the consideration of different modes of heat treatment there are no significant changes.

Conclusion

High-temperature tempering (480 °C) conducted on low carbon martensitic steel 08x2g2NMFB leads to the temper embrittlement and reduces the impact strength by 2.5 times as compared with the impact strength after low-temperature tempering (250 ° C). It has been shown the dependence of the grain size of austenite equal to 5 and 7 microns for the mode of cyclic quenching with high-temperature tempering and one quenching with low-temperature tempering.

Reference list

1. Гусев, А. И. Нанокристаллические материалы / А. И. Гусев, А. А. Ремпель. – Москва : Физматлит : МАИК Наука, 2001. – 222 с. – ISBN 5-9221-0039-4.

2. Ларинин, Д. М. Формирование структуры и повышение конструкционной прочности низкоуглеродистых мартенситных сталей : автореферат диссертации кандидата технических наук : 05.16.01 / Ларинин Данил Михайлович. – Нижний Новгород, 2009. – 18 c.

3. Коган, Л. И. Промежуточное превращение аустенита в углеродистой стали / Л. И. Коган, Р. И. Энтин // Физика металлов и металловедение. 1961. Т. 12, № 2. С. 204–207.

4. Клейнер, Л. М. Конструкционные высокопрочные низкоуглеродистые стали мартенситного класса : учебное пособие / Л. М. Клейнер, А. А. Шацов. – Пермь : Издательство Пермского государственного технического университета, 2008. – 303 с. – ISBN 978-5-88151-874-5 (в пер.).

5. Устиновщиков, Ю. И. Природа отпускной хрупкости сталей / Ю. И. Устиновщиков, О. А. Банных ; отв. ред. К. А. Осипов. – Москва : Наука, 1984. – 239 с.

| Aleksandr Semenov

| Семенов Александр

|

| Perm National Research Polytechnic University

| Пермский Национальный Исследовательский Политехнический Университет

|

| Complex modeling of power supply systems at oil industry enterprises

| Комплексное моделирование систем энергоснабжения на предприятиях нефтяной промышленности

|

| Abstract: The paper presents the concept of synergetic integration of the Building Information Model (BIM) with the energy information model (EIM) and a mathematical description of power consumption and distribution on the example of the electro-technical complex (ETC) of an oil-producing enterprise (OPE). It is assumed that this approach to the facility description will help increase the structural reliability of the power supply system while ensuring uninterrupted power supply.

| Аннотация: В документе излагается концепция синергетической интеграции модели информации о строительстве (МИС) с моделью информации об энергетике (МИЭ) и математическое описание потребления и распределения энергии на примере электротехнического комплекса (ЭТК) нефтедобывающего предприятия (НДП). Предполагается, что такой подход к описанию объекта поможет повысить надежность конструкции системы электропитания при одновременном обеспечении бесперебойного электропитания.

|

Keywords: information modelling, oil-producing enterprise, electric -power engineering

1. Introduction

In the classical sense, modeling is a way of representing and exploring an object. Any model contains information about the object under research, however, the presentation of information can be radically different for different objects. It is important to have an idea of the electro-technical complex (ETC) as a whole to create information models of the power supply facility, since the structure and technical equipment of the facility specify global parameterization and binding to calculated values that affect electricity consumption. For example, if you give an example of an oil-producing enterprise (OPE), then it is necessary to consider the technological indicators of oil production and the nominal parameters of the installed equipment. Various methods of modeling have already achieved high accuracy of calculations and display of relevant information about the ETC in the OPE. But the existing modeling methods function separately, and automated control systems cannot always be used due to high costs and unprofitable implementation, which call for the development of complex modeling of ETC systems at an OPE, using not only established modeling methods, but also using modern 3D visualization methods. So far 3D modeling has been a way to transfer technical information about an object in Russia and in the world. The BIM (Building Information Model) principles have also been developed to convey the complete dataset.

The paper considers the BIM system in conjunction with the energy information model (EIM), which will give complete technical information about the ETC, and together with mathematical modeling will allow controlling the consumption and distribution of electricity [1]. As a result, it will improve energy efficiency while ensuring uninterrupted power supply.

C

C

D

D