Unit EIGHT

TEXT 1

PRINT FINISHING PROCESSES

Finishing (postpress) is a segment of the print production flow in which the printed product is given its requested features of form and functions. The end products produced in the finishing process are characterized by the design (shape) and the functions that are determined by the information content.

The following products are produced in the finishingsector:

• Individual sheets (trimmed sheets, cuttings);

• Folded sheets (sheets in various sizes that are folded according to a certain, sometimes complicated pattern);

• Newspapers (gathered folded sheets);

• Booklets (inserted folded sheets with a cover, stitched with wire or thread in the spine, secure binding);

• Brochures (single or multi-layer blocks, stitching or perfect binding, cover (mostly made of heavier stock);

• Hardcovers (multi-layer block, thread stitching or perfect binding, cover consisting of several parts (usually referred to as a book);

• Assortment of sheets (binding technique: mechanical (very often detachable), comb or spiral bindings using metal or plastic);

• Packing material (open or closed material, cut to size and formed to hollow bodies during the packaging procedure).

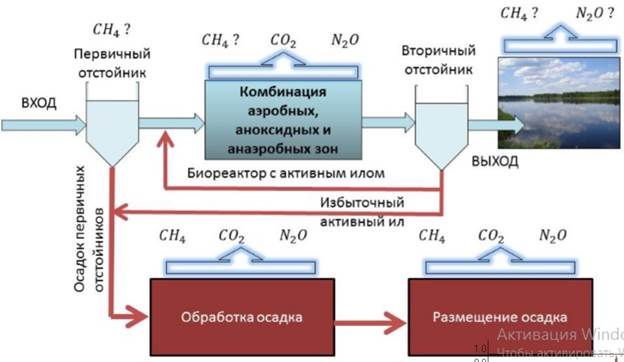

Рис. 9

The following operations are carried out in the process sections:

1. Cutting and die-cutting

The cuttingprocedure is carried out in several print finishing procedures. The main applications are:

• Paper cutting. It also involves cutting piles of print sheets to bookbinding sheets. Paper cutting is also referred to as cutting through;

• Cutting webs. Printed paper webs are cut in web presses or in separate reel slitters to part webs (ribbons) or sheets;

• Trimming.The three-page trim of books and brochure blocks after block binding is referred to as trimming;

• Cutting case material to size. Boards, cardboard sheets, endless cardboard, as well as sheets and webs for book case material are cut to size for book cover production or jackets.

Cutting materials to size also takes place within binding, joining additional parts, and packing processes.

Die-cutting is a process in which materials are cut in a specific pattern. Normally these products are produced in a closed cutting line. Sometimes open cuts are produced, for instance, to round off corners on book blocks, playing cards, and so on, as well as register punching (index thumb, index sequential, etc.). Perforating, where material is removed, is also referred to as a die-cutting operation.

Folding

Foldingis the sharp-edged bending of paper webs or sheets under pressure at a prepared

or unprepared bending point along a straight line according to specified dimensions and folding layouts. The folding line is referred to as the fold.

Folding machines are primarily designed according to two principles of function:

• the buckle fold principle;

• the knife fold principle, also known as the right-angle fold principle.

Buckle Fold Principle. The bookbinding sheet is transported through the upper and lower folding roller into the buckle plate. The sheet bumps against the buckle stop so that due to the movement of the folding roller a buckle is created. The buckle is now taken up by the lower folding rollers. The fold is created between the folding rollers.

Knife Fold Principle. The bookbinding sheet is fed between the folding knife and the folding roller. The folding knife adjoins the sheet of the specified folding line between the folding rollers. Between the folding rollers the fold is formed.

Forwarding

Folded signatures, sheets, or inserts are jointed by bonding means (e.g., glued) or loosely

inserted in the folded sheet. The forwarding process is generally followed by gathering into blocks partial products.

One possibility to minimize the forwarding process is the integration into earlier (folding) or later (e.g., gathering) processes. This is often the case when pasting cards to magazine sheets and when gluing on end papers for book blocks.

Endpapersare vital construction elements for hard covers since the pasting of the book block to the book cover takes place through the endpapers on the first and last signature. Endpapers are folded sheets (in industrial bookbinderies usually quarter sheet) made from particularly bend-resistant papers that are glued with an adhesive strip to the back edge in front of the first text sheet and behind the last text sheet. When connecting block and cover, in each case the outer endpaper is glued across the whole surface onto the case of the book cover. The connection between book block and cover can break easily when no endpapers are used and when the first and last sheet of the book block are glued to the cover.

Assembling into books

Assemblingis the production of a specific sequence of folded sheets, leafs, or webs into a loosely jointed block.

Gathering or inserting into blocks is an assembly processwith the transition into a different processing dimension(folded sheets into one book block). This resultsin organizational, planning, and intermediate storageproblems with a varying number of signatures in consecutive jobs.

5. Blocks binding

Blocks bindingis the production of a temporary or permanent connection of the collated

book block by positive, non-positive, or bond jointing processes (held together by force, fixing elements or adhesives).

Materials and partial products to be processed are:

• collated multi-layer blocks and loose-leaf blocks,

• inserted single-layer blocks,

• folded sheets.

Different methods of binding exist. They are:

• thread-stitching;

• perfect binding;

• thread-sealing;

• wire-stitching.

Trimming

Blocks for hardcovers and brochures are cut on one, three (or four) sides to the final format, whereby the closed fold edges on the head, foot, and front side of the block are eliminated, if this is intended for the product. Materials and partial products to be processed are:

• bound book blocks;

• multi-layer brochures;

• back-stitched brochures;

• leaf assemblies.