A marine evaporator is normally used to provide high quality distillate from seawater for the vessel's water systems. There are many types of evaporators, but they are all designed for the same purpose. Hot cooling water or auxiliary steam is often used as a heat source increasing cost effectiveness.

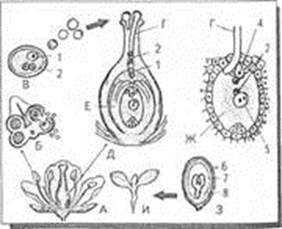

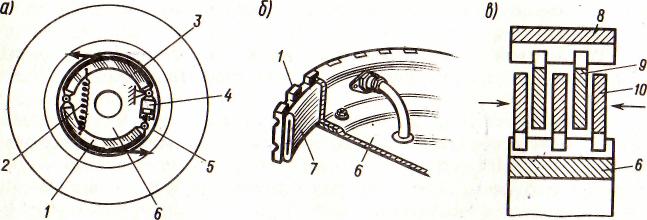

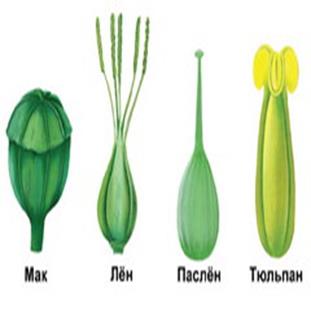

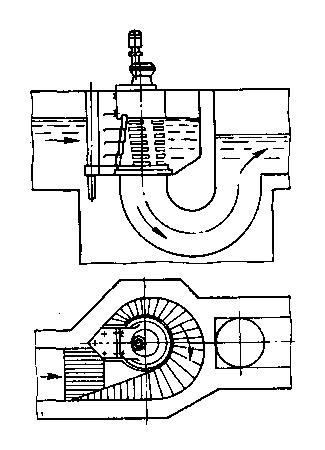

In some type of evaporators, seawater is heated or flows over a series of coils or tubes through which auxiliary steam is passed. Heat is transferred to the seawater under vacuum, vaporizing a major portion of the water. The resulting vapor is scrubbed by a mist eliminator as it leaves the evaporator unit to remove entrained moisture which contains a small amount of dissolved solids.

The vapor is then cooled in a condenser to produce pure distillate. It is pumped to storage tanks for use as boiler water makeup, engine cooling water, potable water and other domestic purposes.

The majority of dissolved solids are left behind, accumulated and concentrated in the brine section of the unit for overboard discharge. The purified water now contains only traces of minerals which can be easily handled with boiler and cooling water treatment chemicals.

Evaporator Scaling

During the evaporation process, the solubility of most of the dissolved minerals, which remain in the evaporator brine, is exceeded and precipitation occurs, forming scale deposits on heat transfer surfaces. The three most common scales formed in an evaporator are calcium sulfate, calcium carbonate, and magnesium hydroxide. These are efficient heat transfer barriers. Reduced heat transfer results in reduced water production. Eventually, distillers must be shut down and cleaned to remove the insulating scale.

Evaporator Foaming and Carryover

The higher concentration of dissolved solids in the brine increases the surface tension of the water, acting like an elastic skin at the water level. The increased surface tension hinders the release of vapor bubbles and gases and promotes foaming. When the bubbles burst, droplets containing concentrated salts are thrown into the vapor space and are carried over into the distillate. This results in reduced water quality. Foaming also may be caused by "organic" substances in the water, which are formed by the decay of organic materials or contamination with petroleum products.

Mechanical Control

Foaming and carryover from evaporators can be minimized by proper management of the water level and salinity (brine) control.

• Improper water level control is often due to the malfunction of the automatic controls and alarms. Automatic equipment and alarms should be maintained in good operating condition.

• Salinity control is an important factor in the prevention of scale deposits as well as carryover. Salinity management refers to the continuous removal of concentrated brine from the evaporator in order to control the amount of dissolved solids buildup. Normally the brine concentration should be maintained at 1.5 (1.5/32nds) concentrations, although some vapor compression units operate at 2.0 (2.0/32nds) concentrations or more.

Chemical Treatment

The problems of scale formation and foaming can be minimized by the addition of chemical treatments containing polymeric scale inhibitors and antifoams. The polymer molecules attach themselves to the scale-forming minerals to disrupt the densely packed crystalline structure. This prevents hard scale from building up on the heat transfer surfaces. Instead, nonadherent, suspended crystals are formed which will easily flow overboard with the brine discharge.

Polymer treatments can remove existing scale from heat transfer surfaces by the same action. If treatment is used, water production can be maintained, and acid cleaning to remove scale can be minimized. Modern formulations include an antifoam ingredient which reduces the surface tension of the water and allows vapor to escape without the formation of foam. This helps to maintain water quality.

EXERCISES

Exercise 1.Read these word combinations and remember their translation.

On the common premise, used onboard for whatever purpose, primarily, to be safely used for steam production, the salts and other contaminants, an evaporator or distiller, purifying the water, to contain only trace levels of minerals, dissolved gases, formed by decaying organic matter, deaeration, the efficient maintenance of all steam generating and cooling system equipment, the desalination of seawater, the most widely used method, routine program, relative simplicity, cost effectiveness, hardness constituents, solutions of different dissolved solids concentration, a semipermeable membrane, the more dilute solution, in the reverse direction, the dilute side, high quality distillate, over a series of coils or tubes, a mist eliminator, the solubility of the dissolved minerals, heat transfer surfaces, the surface tension of the water, the decay of organic materials, the malfunction of the automatic controls and alarms, polymeric scale inhibitors and antifoams, the densely packed crystalline structure, suspended crystals.