where the fuel gas and oxygen mix, and a tip where the flame issues from.

The regulators are attached to the fuel and to the oxygen sources. The oxygen regulator is attached to the oxygen tank and drops the pressure from about 21000 kPa (3000 lbf/in² = 200 atmospheres) to a lower pressure for the torch. This pressure can be adjusted to suit the job at hand by turning a knob on the regulator, and can be set from 0 to about 700–1400 kPa (100–200 lbf/in²). Likewise the fuel regulator is attached to the fuel source and drops the pressure to a level for the torch to use. For acetylene this is 0 to 100 kPa (15 lbf/in²).

The flexible hoses connect from the regulators to the torch and carry the fuel gas and the oxygen. The fuel gas connections have left hand threads and the oxygen connectors have right hand threads so that the two cannot be interchanged, so as to help prevent accidents.

The welder wears goggles or a shield with a shaded lens to protect his eyes from glare and flying sparks and splatter, and wears leather gloves to help protect his hands from burns. He should also wear clothes and shoes appropriate for welding. Sunglasses are not adequate.

Note that the procedures and equipment used for gas welding are essentially the same as for gas brazing.

]

Setting up the equipment When using fuel and oxygen tanks

Setting up the equipment When using fuel and oxygen tanks

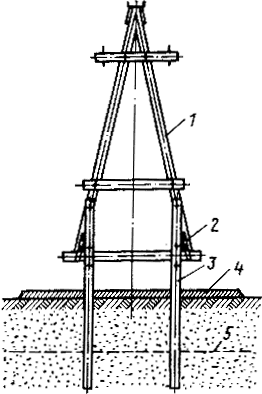

they should be fastened securely to a wall, a post or a portable cart in an upright

Oxygen Rich Butane Blow Torch Flame position. An oxygen tank is especially dangerous for the reason that the oxygen is

at a pressure of 21 MPa (3000 lbf/in² = 200 atmospheres) when full and if the tank falls over and the valve strikes something and is knocked off, the tank will become an unguided and unpredictable missile powered by the compressed oxygen. It is for this reason that an oxygen tank should never be moved around without the valve cap screwed in place.

at a pressure of 21 MPa (3000 lbf/in² = 200 atmospheres) when full and if the tank falls over and the valve strikes something and is knocked off, the tank will become an unguided and unpredictable missile powered by the compressed oxygen. It is for this reason that an oxygen tank should never be moved around without the valve cap screwed in place.

Never lay the acetylene tank down while being used, as the acetone would start

Fuel Rich Butane Blow Torch Flame to come out through the valve. If it was laid down while being transported, it must be set upright, valve on top.

After the oxygen tank is securely fastened, remove the valve cap. With the valve opening pointed away from the welder, open the valve slightly for just a moment and then close it. This serves two purposes. For one, it blows out any dirt or dust that may have settled in the valve. This dirt would otherwise end up in the regulator and shorten its life and accuracy. For another, when a tank is filled, the worker has a tendency to tighten the valve securely to make certain it is closed completely. It is better to break it loose now than when the regulator is in place. Attach the oxygen regulator and tighten the nut. Never use pliers, as the pliers will soon damage the brass nut; always use a wrench. Also, there is a tendency of welders to over tighten the nut. If it is not leaking, then it is tight enough. If a great amount of torque is needed to stop it leaking, or if it will not stop leaking in spite of any amount of tightening, then there is something wrong with the nut, the gasket or the valve.

Attach the fuel regulator to the fuel tank in the same manner. The nut on the fuel regulator usually has left hand threads.

Attach the flexible hoses from the regulators to the torch. The oxygen hose is usually colored green and the fuel hose red. The fuel hose has left hand threaded connectors at both ends and the oxygen has right hand threaded connectors.

With the valves on the torch closed, and the knobs on the regulators screwed out until loose (0 setting), open the valves on the fuel and oxygen tanks. Open the oxygen valve slightly and then wait while the high pressure gauge on the regulator stops rising. Then open the valve fully, until it stops turning. This is a back stop valve. Turning the valve all of the way out prevents leakage through the packing of the valve.

Open the fuel valve also. Only open an acetylene valve one quarter turn. This helps prevent the acetylene from being drawn off too quickly. If acetylene 'bubbles' too rapidly from the acetone, it might become unstable. Open the valve on a LPG tank out completely as on an oxygen tank and for the same reasons.

If there are any leaks in the connections, regulators or torch, or any other faults with the equipment, a safety hazard exists. The equipment should not be used.

Never oil an oxygen regulator. It will cause a fire or explosion — solid brass regulators can be blown apart from the force. Keep oxygen away from all combustibles.

The flame

After this preparation, set the regulators at the desired pressure. For acetylene, this should never be more than 103 kPa (15 lbf/in²). To prevent a large yellow, sooty flame when first lighting the torch, open both the fuel and the oxygen valves (more fuel than oxygen), and light a flame with a 'striker' or by some other means. After the flame is adjusted to the proper size, open the oxygen valve and adjust it to give the desired balance of fuel and oxygen. Usually a neutral flame is used: this is a flame where the fuel and oxygen supplied to the torch tip are both completely combined with each other. An oxidizing flame has an excess of oxygen and a reducing flame has an excess of fuel (carbon). An oxidising flame is used for cutting and a reducing flame is used for annealing e.g. to soften steel sheet metal.

An acetylene flame (as is characteristic of most fuel/oxygen flames) has two parts; the light blue to white colored inner cone and the blue colored outer cone. The inner cone is where the acetylene and the oxygen combine. The tip of this inner cone is the hottest part of the flame. The outer cone is where hydrogen and carbon monoxide from the breakdown of the acetylene and partial combustion of the inner cone combine with the oxygen in the surrounding air and burns.

A neutral flame has a well defined inner cone. A reducing flame has a feathery inner cone. An oxidizing flame has a smaller inner cone that is sharply defined and is pale blue. The welder observes this while adjusting the fuel and oxygen valves on the torch to get the correct balance for the job at hand. There is also a difference in the noise the flame makes. Adjusting the flame is not a hard thing to do after a little experience and practice.

The size of the flame can be adjusted to a limited extent by the valves on the torch and by the regulator settings, but in the main it depends on the size of the orifice in the tip. In fact, the tip should be chosen first according to the job at hand, and then the regulators set accordingly.

The flame is applied to the base metal and held until a small puddle of molten metal is formed. The puddle is moved along the path where the weld bead is desired. Usually, more metal is added to the puddle as it is moved along by means of dripping metal from a wire ("welding rod" or "filler rod") into the molten metal puddle. The force of the jet of flame issuing from the torch tip helps to manipulate the puddle. The amount of heat can be controlled by the distance of the flame from the metal. There should be a bright, incandescent spot on the molten puddle. When the puddle is correctly maintained, a sound weld will result.

The blowtorch

Setting up the equipment When using fuel and oxygen tanks

Setting up the equipment When using fuel and oxygen tanks at a pressure of 21 MPa (3000 lbf/in² = 200 atmospheres) when full and if the tank falls over and the valve strikes something and is knocked off, the tank will become an unguided and unpredictable missile powered by the compressed oxygen. It is for this reason that an oxygen tank should never be moved around without the valve cap screwed in place.

at a pressure of 21 MPa (3000 lbf/in² = 200 atmospheres) when full and if the tank falls over and the valve strikes something and is knocked off, the tank will become an unguided and unpredictable missile powered by the compressed oxygen. It is for this reason that an oxygen tank should never be moved around without the valve cap screwed in place.