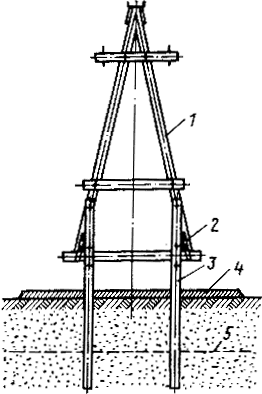

Особенности сооружения опор в сложных условиях: Сооружение ВЛ в районах с суровыми климатическими и тяжелыми геологическими условиями...

Кормораздатчик мобильный электрифицированный: схема и процесс работы устройства...

Особенности сооружения опор в сложных условиях: Сооружение ВЛ в районах с суровыми климатическими и тяжелыми геологическими условиями...

Кормораздатчик мобильный электрифицированный: схема и процесс работы устройства...

Топ:

Марксистская теория происхождения государства: По мнению Маркса и Энгельса, в основе развития общества, происходящих в нем изменений лежит...

Установка замедленного коксования: Чем выше температура и ниже давление, тем место разрыва углеродной цепи всё больше смещается к её концу и значительно возрастает...

Интересное:

Распространение рака на другие отдаленные от желудка органы: Характерных симптомов рака желудка не существует. Выраженные симптомы появляются, когда опухоль...

Уполаживание и террасирование склонов: Если глубина оврага более 5 м необходимо устройство берм. Варианты использования оврагов для градостроительных целей...

Подходы к решению темы фильма: Существует три основных типа исторического фильма, имеющих между собой много общего...

Дисциплины:

|

из

5.00

|

Заказать работу |

|

|

|

|

Standing Orders

When watch engineers are to call the chief engineer

1. IF any fire, no matter how small, is discovered in any machinery space or in any other part of the ship.

2. IF the generator trips off (выключаться, отключаться) the line or any difficulty is experienced in maintaining constant frequency, voltage or load requirements.

3. IF the temperature of the generator stator or rotor increases suddenly or exceeds the prescribed limits.

4. IF any difficulty is experienced in maintaining a steady water level in boilers or any difficulty in maintaining satisfactory operation of the boiler feed pump or water level regulations.

5. IF there is any increase in consumption of make-up feedwater (питательная вода).

6. IF there is any seawater leak in main condenser, auxiliary condenser or other system that is contaminating the boiler feed system.

7. IF any difficulty is experienced with water in fuel or loss of fires.

8. IF pressure drop across generator, superheater or economizer tube banks (пучок трубок) exceeds limit marked on boiler front.

9. IF any local or general overheating of boiler casing is discovered.

10. IF superheat temperature should show abnormal increase that is not corrected by adjustment of excess air.

11. IF any difficulty is experienced in keeping bilges pumped dry.

12. IF any air, oil, fuel, water or steam leaks occur that are other than minor.

13. IF any difficulty is experienced with plugged or choked sea chest (кингстонная коробка).

14. IF any leak is discovered in any sea connection valve or fitting, especially in the body (корпус клапана), bonnet (крышка или колпак) or joint (соединение или разъем).

15. IF bridge requests speed increase requiring a greater steam flow to H.P. turbine than the limit set by chief engineer’s standing orders.

16. IF any unusual, concentration of dirt or foreign matter, especially particles, is discovered in the main lubricating oil strainers.

17. IF any abnormal temperature rise is noticed in the main turbine, reduction gear, line shaft or turbo generator bearing.

18. IF any unusual vibration is noticed, especially in the main propulsion system or turbo generators.

Exercise 6. Translate the sentences into Russian.

1.When taking over the underway watch the engineer is considered the oncoming watchkeeper and at such time he shall obtain all relevant information from the engineer that he is relieving and that is called the offgoing watchkeeper. 2. Both engineers shall make a joint inspection round of the machinery spaces, note the condition of machinery, equipment, piping and bilges, take fuel oil meter readings and standard entries in the engineer’s log. 3.The watchkeepers shall maintain cleanliness in machinery spaces, take precautions to avoid fire hazards, clean strainers and filters, discharge separators, change-over from running to stand-by machinery components. 4. During the watch watchkeeper will check operating pressures and temperatures, liquid levels and flows, running machinery bearing for overheating, piping for leakage, plant components for unusual (excessive) noise or vibration, alarms and automatic control devices for proper functioning, availability and operable condition of fire-fighting and safety equipment. 5. Are there any problems with fuel and lube oil pipes, tubes or hoses? – There are no leaks on piping, all joints are tight. 6. Have you taken the pressure gauge reading? – Yes, I have. Circulating oil pressure is 3.5 kg/cm2, which is above normal, valve gear lube oil pressure is 1 kg/cm2, it’s normal and cooling water pressure is 0.5 kg/cm2, I think it’s below normal. 7. What is the sounding in the port fresh water tank? – Fresh water sounding is 6.5 meters. 8. What does the order “Stand by engine” mean? – It means that engine-room personnel are fully ready to manoeuvre. 9. Do you know the standard engine orders? – They are Full/Half/Slow/Dead slow ahead or astern; Emergency full ahead or astern. 10. Is there any break down of machinery? – Blackout in boiler room

|

|

Exercise 7. Translate the sentences into English.

1. Вахтенный моторист подчиняется непосредственно вахтенному механику и выполняет распоряжения под его присмотром. 2. Мотористведет контроль за работой порученных ему действующих технических средств, немедленно докладывает вахтенному механику о замеченных неполадках в работе технических средств и принимает меры к их устранению. 3. Вахтенный моторист поддерживает в машинном отделении чистоту и порядок. 4. Перед запуском любого механизма необходим его наружный визуальный осмотр. 5.Вахтенному мотористу без разрешения вахтенного механика категорически запрещается производить работы, связанные с вводом и выводом действующего технического средства, за исключением случаев, связанных с угрозой жизни. 6. Я еще не проверил те механизмы на правильность работы. 7. Он проверил рабочие давления и температуры, а также подшипники на перегрев. 8. Моторист действует в соответствии с распоряжениями вахтенного механика. 9. Вы можете заменить неисправное оборудование? – Да, но только в присутствии вахтенного механика. 10. Все произведенные замеры в топливных цистернах и снятые показания приборов должны быть занесены в журнал машинного отделения.

Combustion defects

Normally the combustion in each power cylinder should be smokeless and complete and occur early in the stroke. Insufficient breaking up of the oil during injection will cause slow and incomplete burning and may be the result of clogged fuel nozzles, oil too cold or incorrect timing. Other causes of incomplete burning are compression too low, injection valves not correctly timed and air inlet pipes clogged.

|

|

Lubricating system defects

All Diesel engines today are lubricated by the forced feed method and no hand oiling of any part is required. This requires that the engine housings be closed in, to prevent loss of oil through splashing, and the oil piping, with the oil circulating pump, forms a closed circuit through which the same oil circulates repeatedly. Of course the most serious derangement in such a system is loss of pressure.

Air system defects

The most serious derangement that can occur in the air system of an air injection engine, aside from the remote possibility of an explosion, is loss of injection air. Assuming that the compressor suction is open and the bleeder valve in the first stage properly adjusted, a falling off in the air pressure may be due to leaky, broken or stuck compressor valves, an injection valve sticking open, leaky air valve stem packing, leaky joints in the air piping or failure of the cooling water supply. If the air pressure falls to somewhere near the compression pressure in the power cylinders, unless the trouble can be located immediately, the engine should be stopped. If the engine is kept running, there will be a possibility of an explosion inside the injection valve body.

Operating troubles in general. Water in fuel oil. Water may get into the fuel oil by leakage through defective riveting of tanks, through alternate use of tanks for fuel oil and water ballast, or the fuel oil as delivered into the tanks may contain considerable moisture that will settle out. The degree of seriousness of the resulting troubles will vary with the amount of water in the oil, but among the possibilities are cracked heads and pistons, burned out exhaust valves, low compression due to wear of rings and liners, and irregular running of the engines.

Improperly refined oil. Fuel oil must, during the refining process, be treated with sulphuric acid and this acid must later be neutralized with soda. If this neutralizing agent is not thoroughly washed out of the oil, its presence cannot be detected without chemical analysis nor is it removed by the filtering and straining methods ordinarily used on shipboard. When the engine is opened up after running on this insufficiently washed oil the entire surface of the combustion spaces in the cylinders will be found to have a coating of gritty material which looks and feels like sand but which is mostly sodium sulphate. It does not cause any immediate derangement of the engine but it does cause considerable wear of piston rings and cylinder liners. When such deposits are found the only remedy is to stop using the fuel from that particular refinery.

Loss of power or slowing down of engine. When this occurs the first possibility that should be investigated is hot bearings. Other causes are failure of fuel to one or more cylinders, derangement of valves of valve gear or a fall in cooling water temperature. A decided reduction of the sea water temperature will often be experienced when entering a river from the sea, passing out of the Gulf Stream or leaving tropical waters. When this occurs the cooling water supply should be cut down until the jacket water temperature is up to normal. A distinct loss in efficiency sometimes results from the idea that the jacket water should always be kept as cold as possible.

Cracked cylinders and cylinder heads. Cracks may result from unequal heating due to poor design, bad castings, air pockets in jackets, lack of cooling water and overloading. Modern practice in design and construction has greatly reduced the probability of cracking from the first two causes and watchfulness on the part of the engineers eliminates the other causes, so that cracked heads and cylinders are not nearly so common as they were in the early days of Diesel engineering.

|

|

Cracked crank shafts. During the early development period cracked crank shafts were so common that it was considered one of the inevitable hazards associated with Diesel engine operation. This trouble has become very rare, however, in modern practice.

Vibration. The amount of vibration of an engine and of the ship's hull in which it is installed will depend on how well the reciprocating and rotating masses in the engine are balanced and the position of the engine relative to a nodal point in the hull. These are both matters over which the operating engineer has no control. Normally Diesel engines, especially in the large sizes, run with very little vibration but it sometimes happens that an engine will have a critical speed, a speed at which the twisting impulses imparted to the crank shaft by the pressure acting on the pistons coincide with the natural period of vibration of the crank shaft. When the engine operates at this speed violent vibration will occur that may result in loosening nuts, shaking off small fittings, breaking pipes and even breaking of the crank shaft, if continued long enough.

WATCHKEEPING. PERIODIC SAFETY ROUTINES

Exercise 1. Read and learn the following words and expressions:

| 1. | licenced | дипломированный |

| 2. | to be responsible to | быть ответственным перед кем-либо |

| 3. | to be responsible for | быть ответственным за что-либо |

| 4. | implementation | осуществление, выполнение |

| 5. | to take over the watch | принимать вахту |

| 6. | being relieved, offgoing | механик, которого сменяют |

| 7. | relieving engineer, oncoming | сменяющий механик |

| 8. | to familiarize oneself with | ознакомиться с чем-либо |

| 9. | standing order | постоянный приказ, инструкция |

| 10. | to acknowledge | подтверждать |

| 11. | signature | подпись |

| 12. | prompt | быстрый |

| 13. | in the vicinity | поблизости, в районе |

| 14. | to be engaged in | заниматься чем-либо |

| 15. | reasonable | приемлемый |

| 16. | skylight | световой люк |

| 17. | to grease | смазывать |

| 18. | underway watch | ходовая вахта |

| 19. | before getting underway | до выхода в море, до отплытия |

| 20. | joint inspection round | совместный (проверочный) обход |

| 21. | engineer’s log | машинный журнал |

| 22. | appropriate entry | соответствующая запись |

| 23. | upon the completion | по завершению |

| 24. | impending | неминуемый, предстоящий |

| 25. | stand-by condition | дежурный режим |

Exercise 2. Read and translate the text, paying attention to the words in italics.

Prior to taking over the watch the Engineer of the watch is to examine all machinery and plant particularly the steering gear, refrigerating plant, boilers, main and auxiliary engines and auxiliary equipment. They must inspect all fuel and lubricating oil pipework for leakage. Any defects must be immediately reported to the Engineer of the watch being relieved. The Engineer being relieved is toinform the relieving Engineer of the status of all plant, service tanks and suctions in use and any defects which call for special attention. On taking over the watch the Engineer of the watch is tofamiliarize himself with the standing orders and instructions in the Chief Engineer Order Book and to acknowledge these instructions by his signature.

While keeping a watch at sea or in port the Engineer of the Watch is responsible for the safe and efficient operation of all equipment and machinery, the safety of all personnel in the machinery spaces and for the prompt and efficient response to order from the Bridge or Cargo Control Station. If main engines are operating under Engine Room Control the responsible Engineer shall remain in the vicinity of the engine controls in order to respond rapidly to telegraphed orders. When personnel are engaged in maintenance or other duties within the machinery spaces, the Engineer of the watch shall ensure that they conduct their duties in a safe and efficient manner. At first indication of trouble the engineer on watch shall notify the chief engineer and take immediate steps to prevent damage to machinery. He must report to the chief engineer any change of the ME speed or other orders from the bridge. In case of emergency or malfunction corrective actions should be taken immediately, for example, steam, air, oil or water leaks must be repaired promptly. When any alarm or protective device is found defective the repair or replacement should be carried out at once.

|

|

When the ship is manoeuvring, the engineer on watch devotes his primary attention to complying with the orders from the bridge. All bridge orders shall be promptly executed. Changes in direction or speed of the main propulsion unit shall be recorded.

Before getting underway the engineer on watch jointly with the OOW shall test the ME with necessary auxiliaries, the steering gear, whistle and running lights (ходовые огни). An appropriate entry shall be made in the log. The engineer on watch shall record required data in the log book including any unusual occurrences and he shall sign the log upon the completion of his watch.To avoid any danger to the safety of the ship and its crew, the bridge should be immediately notified in the event of fire, impending actions in machinery spaces that may cause reduction in ship’s speed, steering failure, stoppage of the ship’s propulsion system or any alternation in the generation of electric power or similar threat to safety.

When the engine room is put in a stand-by condition, the engineer on watch shall ensure that all machinery and equipment which may be used during manoeuvring is in a state of immediate readiness and that an adequate reserve of power is available for steering gear and other requirements.

Exercise 3. Give brief answers to the following questions: 1. What are the responsibilities of the engineer on watch/relieving engineer? 2. Who shall remedy any malfunction discovered during the watch? 3. What data shall be recorded in the engineer’s log during the watch? 4. How must bridge orders be executed? 5. In what events shall the engineer on watch notify the bridge immediately? 6. What are the watch engineer’s duties in relation to the engine room that is in a stand-by condition? 7. What do you know about the standing orders? 8. What are the some records that can be made in the engineer’s log? 9. What are the main parameters that should be checked during the watch? 10. What are the safety rules that should be observed during the watch?

Exercise 4. Give equivalents:

· in Russian: to avoid fire hazards, to sign the log upon the completion of the watch, to note the condition of the machinery and equipment, to call the electrical engineer, to maintain cleanliness in the machinery spaces, to execute the orders from the bridge, to notify the chief engineer of any troubles in the engine room, to take immediate steps to prevent damage to machinery, to obtain relevant information the offgoing engineer, to test the whistle and running lights, to change-over to a stand-by machinery components, to check operating temperature and pressure, to record all unusual occurrences in the engineer’s log;

· in English: нести вахту в МО, устранять протечки в трубопроводах, выполнять действия по устранению неисправностей, записывать в машинном журнале все необходимые происшествия/случаи, сдавать вахту, сделать соответствующие записи в машинном журнале, снимать показания счетчика расхода топлива, проверить работающие механизмы на правильность работы, проверить рабочие давление, средства аварийной сигнализации и автоматического управления, проверить подшипники на перегрев, состояние противопожарного оборудования, принимать вахту, производить совместный осмотр машинных помещений, переходить (переключаться) на резервный механизм, определить причину постороннего шума, заменить неисправное оборудование, испытать в работе рулевое устройство,

|

|

Exercise 5. Look through the text and be ready to discuss them.

In addition to watchkeeping and maintenance duties various safety and emergency equipment must be periodically checked. As an example the following inspections should take place at least weekly:

1. Emergency generator should be started and run for a reasonable period. Fuel oil, lubricating oil and cooling water supplies and tank levels should be checked

2. Emergency fire pump should be run and the deck fire main operated for a reasonable period. All operating parameters should be checked.

3. Carbon dioxide cylinder storage room should be visually examined. The release door should be opened to test the alarm and check that the machinery-space fans stop.

4. One smoke detector in each circuit should be tested to ensure operation and correct indication on the alarm panel. Aerosol test sprays are available to safely check some types of detector.

5. Fire pushbutton alarms should be tested, by operating a different one during each test.

6. Any machinery space ventilators or skylights, should be operated and greased, if necessary, to ensure smooth rapid closing.

7. Fire extinguishers should be observed in their correct location and checked for operation.

8. Fire hoses and nozzles should also be observed in their correct places. The nozzles should be tried on the hose coupling. Any defective hose should be replaced.

9. Any emergency batteries, e.g. for lighting or emergency generator starting should be examined.

10. All lifeboats engines should be ran for a reasonable period. Fuel oil and lubricating oil levels should be checked.

11 All valves and equipment operated from the fire control point should be checked for operation, where this is possible.

12. Any watertight doors should be opened and closed by hand and power. The guides should be checked to ensure that they are clear and unobstructed.

Standing Orders

When watch engineers are to call the chief engineer

1. IF any fire, no matter how small, is discovered in any machinery space or in any other part of the ship.

2. IF the generator trips off (выключаться, отключаться) the line or any difficulty is experienced in maintaining constant frequency, voltage or load requirements.

3. IF the temperature of the generator stator or rotor increases suddenly or exceeds the prescribed limits.

4. IF any difficulty is experienced in maintaining a steady water level in boilers or any difficulty in maintaining satisfactory operation of the boiler feed pump or water level regulations.

5. IF there is any increase in consumption of make-up feedwater (питательная вода).

6. IF there is any seawater leak in main condenser, auxiliary condenser or other system that is contaminating the boiler feed system.

7. IF any difficulty is experienced with water in fuel or loss of fires.

8. IF pressure drop across generator, superheater or economizer tube banks (пучок трубок) exceeds limit marked on boiler front.

9. IF any local or general overheating of boiler casing is discovered.

10. IF superheat temperature should show abnormal increase that is not corrected by adjustment of excess air.

11. IF any difficulty is experienced in keeping bilges pumped dry.

12. IF any air, oil, fuel, water or steam leaks occur that are other than minor.

13. IF any difficulty is experienced with plugged or choked sea chest (кингстонная коробка).

14. IF any leak is discovered in any sea connection valve or fitting, especially in the body (корпус клапана), bonnet (крышка или колпак) or joint (соединение или разъем).

15. IF bridge requests speed increase requiring a greater steam flow to H.P. turbine than the limit set by chief engineer’s standing orders.

16. IF any unusual, concentration of dirt or foreign matter, especially particles, is discovered in the main lubricating oil strainers.

17. IF any abnormal temperature rise is noticed in the main turbine, reduction gear, line shaft or turbo generator bearing.

18. IF any unusual vibration is noticed, especially in the main propulsion system or turbo generators.

Exercise 6. Translate the sentences into Russian.

1.When taking over the underway watch the engineer is considered the oncoming watchkeeper and at such time he shall obtain all relevant information from the engineer that he is relieving and that is called the offgoing watchkeeper. 2. Both engineers shall make a joint inspection round of the machinery spaces, note the condition of machinery, equipment, piping and bilges, take fuel oil meter readings and standard entries in the engineer’s log. 3.The watchkeepers shall maintain cleanliness in machinery spaces, take precautions to avoid fire hazards, clean strainers and filters, discharge separators, change-over from running to stand-by machinery components. 4. During the watch watchkeeper will check operating pressures and temperatures, liquid levels and flows, running machinery bearing for overheating, piping for leakage, plant components for unusual (excessive) noise or vibration, alarms and automatic control devices for proper functioning, availability and operable condition of fire-fighting and safety equipment. 5. Are there any problems with fuel and lube oil pipes, tubes or hoses? – There are no leaks on piping, all joints are tight. 6. Have you taken the pressure gauge reading? – Yes, I have. Circulating oil pressure is 3.5 kg/cm2, which is above normal, valve gear lube oil pressure is 1 kg/cm2, it’s normal and cooling water pressure is 0.5 kg/cm2, I think it’s below normal. 7. What is the sounding in the port fresh water tank? – Fresh water sounding is 6.5 meters. 8. What does the order “Stand by engine” mean? – It means that engine-room personnel are fully ready to manoeuvre. 9. Do you know the standard engine orders? – They are Full/Half/Slow/Dead slow ahead or astern; Emergency full ahead or astern. 10. Is there any break down of machinery? – Blackout in boiler room

Exercise 7. Translate the sentences into English.

1. Вахтенный моторист подчиняется непосредственно вахтенному механику и выполняет распоряжения под его присмотром. 2. Мотористведет контроль за работой порученных ему действующих технических средств, немедленно докладывает вахтенному механику о замеченных неполадках в работе технических средств и принимает меры к их устранению. 3. Вахтенный моторист поддерживает в машинном отделении чистоту и порядок. 4. Перед запуском любого механизма необходим его наружный визуальный осмотр. 5.Вахтенному мотористу без разрешения вахтенного механика категорически запрещается производить работы, связанные с вводом и выводом действующего технического средства, за исключением случаев, связанных с угрозой жизни. 6. Я еще не проверил те механизмы на правильность работы. 7. Он проверил рабочие давления и температуры, а также подшипники на перегрев. 8. Моторист действует в соответствии с распоряжениями вахтенного механика. 9. Вы можете заменить неисправное оборудование? – Да, но только в присутствии вахтенного механика. 10. Все произведенные замеры в топливных цистернах и снятые показания приборов должны быть занесены в журнал машинного отделения.

|

|

|

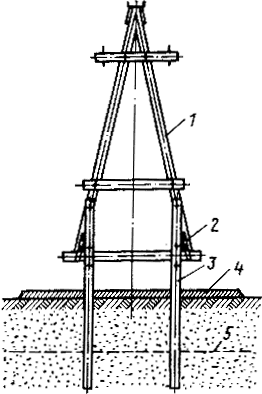

Индивидуальные очистные сооружения: К классу индивидуальных очистных сооружений относят сооружения, пропускная способность которых...

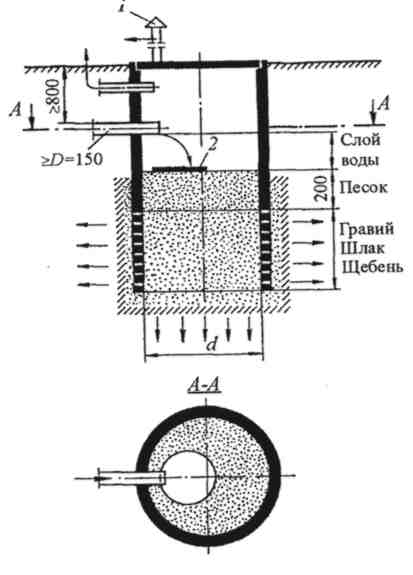

Эмиссия газов от очистных сооружений канализации: В последние годы внимание мирового сообщества сосредоточено на экологических проблемах...

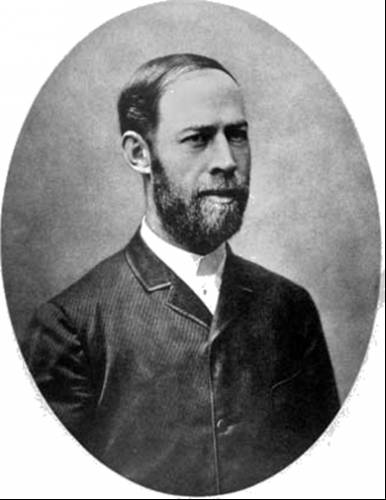

История создания датчика движения: Первый прибор для обнаружения движения был изобретен немецким физиком Генрихом Герцем...

Историки об Елизавете Петровне: Елизавета попала между двумя встречными культурными течениями, воспитывалась среди новых европейских веяний и преданий...

© cyberpedia.su 2017-2024 - Не является автором материалов. Исключительное право сохранено за автором текста.

Если вы не хотите, чтобы данный материал был у нас на сайте, перейдите по ссылке: Нарушение авторских прав. Мы поможем в написании вашей работы!