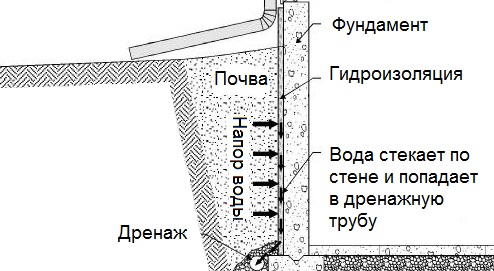

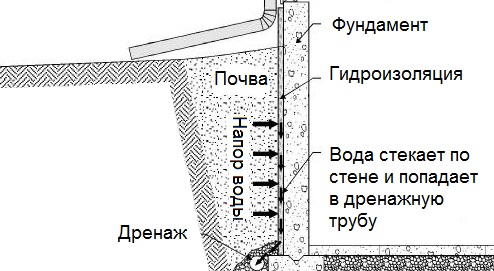

Общие условия выбора системы дренажа: Система дренажа выбирается в зависимости от характера защищаемого...

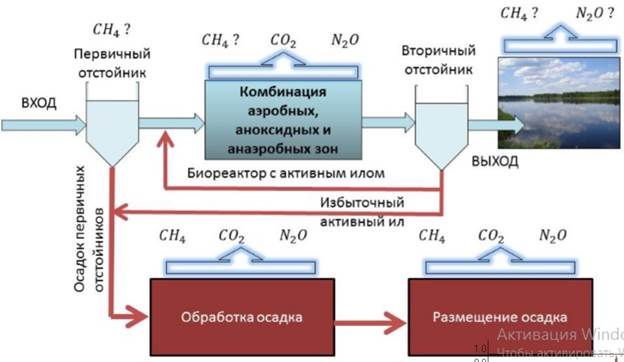

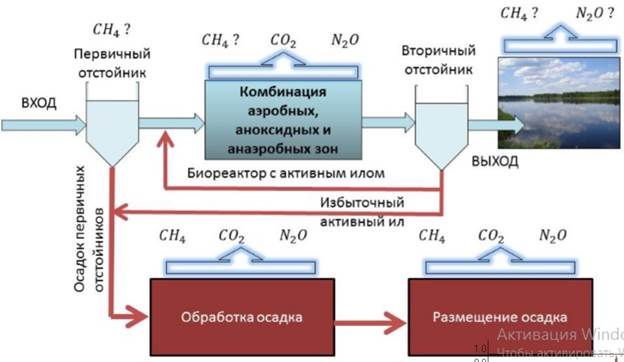

Эмиссия газов от очистных сооружений канализации: В последние годы внимание мирового сообщества сосредоточено на экологических проблемах...

Общие условия выбора системы дренажа: Система дренажа выбирается в зависимости от характера защищаемого...

Эмиссия газов от очистных сооружений канализации: В последние годы внимание мирового сообщества сосредоточено на экологических проблемах...

Топ:

Генеалогическое древо Султанов Османской империи: Османские правители, вначале, будучи еще бейлербеями Анатолии, женились на дочерях византийских императоров...

Определение места расположения распределительного центра: Фирма реализует продукцию на рынках сбыта и имеет постоянных поставщиков в разных регионах. Увеличение объема продаж...

История развития методов оптимизации: теорема Куна-Таккера, метод Лагранжа, роль выпуклости в оптимизации...

Интересное:

Принципы управления денежными потоками: одним из методов контроля за состоянием денежной наличности является...

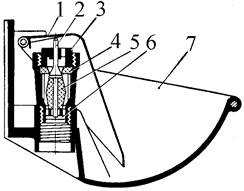

Средства для ингаляционного наркоза: Наркоз наступает в результате вдыхания (ингаляции) средств, которое осуществляют или с помощью маски...

Наиболее распространенные виды рака: Раковая опухоль — это самостоятельное новообразование, которое может возникнуть и от повышенного давления...

Дисциплины:

|

из

5.00

|

Заказать работу |

1. Плоская офсетная печать, которую часто называют просто офсетом, является самым распространенным способом коммерческой печати. 2. Вы слышали фразу “масло и вода не смешиваются”? Это можно сказать о краске и воде. Это отличительный принцип плоской печати. 3. На формах для литографской печати область изображения вбирает краску, а область без изображения её отталкивает. 4. На офсетных печатных формах есть участки гидрофильные, “водовосприимчивые”, и участки “красковосприимчивые”. Вода распределяется по гидрофильным участкам; краска, которая не смешивается с водой, удерживается на “красковосприимчивых” участках.

5. При смачивании увлажняющий раствор в процессе печати ровным слоем растечется по поверхности пробельных участков, образуя сплошную пленку. Краска перейдет только на участки изображения. 6. В типографиях обычно используют увлажняющий раствор, который представляет собой смесь воды и спирта или его заменителя. 7. Для переноса изображения с печатной формы на бумагу необходимо устройство, которое называется печатной секцией. 8. Вначале форма соприкасается с увлажняющими валиками, которые наносят на её поверхность увлажняющий раствор. Далее форма вступает в контакт с валиками красочного аппарата. 9. При вращении формного цилиндра изображение переходит на офсетное полотно, которое закреплено на офсетном цилиндре. 10. С офсетного полотна изображение переходит на запечатываемый материал, который с достаточно сильным давлением прижимается к полотну печатным цилиндром.

11. Complete the Quiz:

| 1 | |||||||||||

| 2 | |||||||||||

| 3 | |||||||||||

| 4 | |||||||||||

| 5 | |||||||||||

| 6 | |||||||||||

| 7 | |||||||||||

| 8 | |||||||||||

| 9 | |||||||||||

| 10 | |||||||||||

| 11 |

1. Relief printing process, invented by Johannes Gutenberg.

2. Coloured mixture, used for writing and printing.

3. A force, related to the stretching.

4. Non-printing areas of the offset printing plate.

5. To print an image by indirect transferring.

6. The production or imitating of any texture on any surface, making smooth metal sheet coarse.

7. Technology for creating the images, based on the theory of three-colour vision.

8. The parts of the printing plates which are covered or not by the ink.

9. Image carrier in conventional methods of printing.

10. Ink-accepting and water repellent.

11. One of the subtractive primaries.

TEXT 2

OFFSET PRINTING TECHNOLOGIES

Sheet-fed Offset Printing

Sheet-fed offset printing has impressive economic and qualitative advantages over other printing technologies. Fundamental attributes of sheet-fed offset are flexible production options and the relatively economical production of printed products of a very high quality for a wide range of print volumes. The color combination ranges from one to four-color prints up to twelve-color prints (with perfecting). In sheet-fed offset printing, substrates of different sheet sizes and grammages are processed and these can generally be obtained off-the-shelf at short notice.

Just as important for the client as the free choice of format is the range of special substrate qualities. The great variety of standard substrates for sheet-fed offset necessitates well-organized stock-keeping in the paper industry. In-line or off-line finishing operations, such as coating, imprinting, numbering, perforating, and punching are popular technologies used in sheet-fed offset. And finally the sheet finishing variants available are virtually inexhaustible.

A sheet-fed offset press must basically perform the following tasks:

• provide a high-precision conveyance of the flexible substrate at high speeds, under very dynamic, process-specific strains;

• enable a complicated printing process, involving several material flows (of dampening solution, ink, paper, air), to run in a controlled and reliable way.

High-precision conveyor systems, guide elements, and monitoring systems are necessary in order to route the sheet from the feed pile via the feeder, through the printing units, and finally to the delivery, where the printed sheet is stacked in a pile again.

There is a great variety of constructive solutions for feeder variants used in printing and print finishing machinery. Single-sheet feeders or stream feeders are found on sheet-fed offset presses.

The single-sheet feeder has the advantage that it is easier to adjust to the sheet size and the paper quality. High-speed presses processing large formats, on the other hand, are exclusively equipped with stream feeders, so that the highly dynamic processes and the accurate sheet alignment can still be mastered in accordance with quality requirements.

The feed system has the task of picking up the sheets from the feed pile, separating them, conveying them to the feed table via a feed system, and aligning them at the feed guides. Since each sheet is individually aligned at the feed guides the print image can be positioned on the sheet with an adequate degree of accuracy (position in relation to the paper edges and, if applicable, to a preprinted image on the front or reverse side).

Sheets are usually printed on both sides. To achieve this, they have to pass through the press a second time, unless a perfecting press is being used, in which straight printing and perfecting can be done in one pass.

Work and Turn. For the second pass (verso printing) the sheets are usually turned over before being prepiled again. This means that the pile is turned so that the side edges are changed over.

So that the sheet can always be aligned at the same three points, the sheet-fed offset press needs a second side lay on the opposite side from the first side lay. After work and turn, the second side lay has to be used to ensure an accurate register alignment. The change of side lay after work and turn only becomes unnecessary if all sheets in the pile are of the same size. Only then can the accurate register alignment be ensured for the front and reverse sides without having to change the side lays.

In the production print sheets, meaning that the individual sheets differ in size slightly within a pile. The knife on the guillotine cutter can deviate (under or over-cutting) or the sheet “works” and changes its size due to moisture absorption and ambient temperature. The problem here is that the change in sheet sizes can differ considerably from section to section within the pile. Already in the first sheet pass, the sheets in the pile are not equally dimensioned and the differences from section to section are even greater in the second pass. However, since the side guide is changed after work and turn, so that the sheet is aligned at the same three feed points for straight printing as for verso printing, an accurate register can be maintained throughout the print run for both sides. This production accuracy for the finished product can, however, only be achieved if the same alignment points are used throughout all finishing operations.

Work and Tumble. The pile can also be inverted to print the second side, which means that the edge of the sheet that was the front edge for the first side becomes the rear edge for the second side. In this way the lead edge of the sheet becomes the rear (trailing) edge. With work and tumble, exact straight printing and verso printing register can only be achieved if the distance between the front and rear edges of each individual sheet is exactly the same throughout the entire print run. As already explained, the paper’s dimensions may change and this makes it necessary for all four sides of the sheets to be trimmed shortly before printing. Work and tumble layouts must include two gripper margins, whereas with work and turn one gripper margin suffices. It is on account of these complexities that work and tumble is only rarely used.

The ability to switch over the sheet travel from straight printing to perfecting necessitates a sheet turning device (perfector) between the printing units, where the sheet is reversed (“work and tumble”) at full production speed for printing in-line on both sides of the sheet. These types of presses are called “perfecting presses”.

A quite considerable simplification and increased productivity on the part of perfecting presses is obtained with this “in-line turning” because the sheet needs to be aligned only once in the press; it is not necessary to re-align the sheet to the second gripper margin after sheet reversal.

Striving for a more cost and time-effective print production has lead to the development of perfecting presses that allow printing on both sides of a sheet in one pass. It is more cost and time-intensive to run a sheet through the press a second time to print the reverse side than it is to print both sides in a single pass.

Web-fed Offset Printing

Web-fed offset presses are production flow lines where the product is also a means of transportation. Web offset presses are usually categorized into either press types operating on the heatset principle for the production of commercial print jobs, magazines, and publications or newspaper offset presses operating on the coldset principle.

A printing couple is the single component used to print ink on one web or sheet side characterized by a plate cylinder and a blanket cylinder (couple) with associated dampening and inking units, whereas a printing unit in web offset printing is composed of several printing couples combined into one closed unit. The simplest version of a printing unit is the vertical blanket-to-blanket one which uses a horizontal web-lead to print one color on the front and reverse side of the web. The printing section is composed of two printing couples arranged in tandem.

In newspaper printingunits are arranged more often horizontally than in the vertical because multi-web production is most widely used and it is easier to gather the individual color-printed sections in a vertical line before the individual webs are merged horizontally.

ESSENTIAL VOCABULARY

Words and Word Combinations

ACTIVITIES

Индивидуальные и групповые автопоилки: для животных. Схемы и конструкции...

Своеобразие русской архитектуры: Основной материал – дерево – быстрота постройки, но недолговечность и необходимость деления...

Типы оградительных сооружений в морском порту: По расположению оградительных сооружений в плане различают волноломы, обе оконечности...

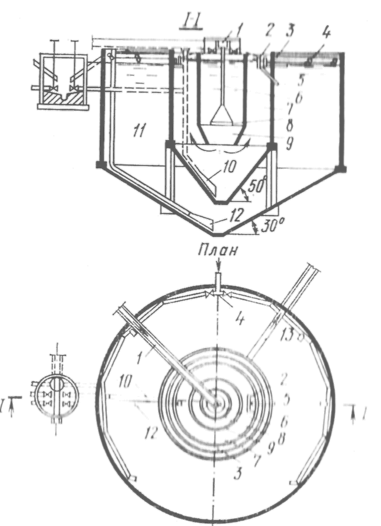

Типы сооружений для обработки осадков: Септиками называются сооружения, в которых одновременно происходят осветление сточной жидкости...

© cyberpedia.su 2017-2024 - Не является автором материалов. Исключительное право сохранено за автором текста.

Если вы не хотите, чтобы данный материал был у нас на сайте, перейдите по ссылке: Нарушение авторских прав. Мы поможем в написании вашей работы!