TREE LENGTH LOGGING SYSTEM CIRCA 1972

(Система машин заготовки хлыстов)

(Система машин заготовки хлыстов)

| chain saw

feller-buncher

bunch

skidder

to drag

landing

forwarder

delimber machine

limb

slasher machine

length

to stack

pile

truck

rut

skidding trail

| цепная пила

валочно-пакетирующая машина

пакет, пачка (деревьев, хлыстов)

трелевочник

подтаскивать, тащить

склад, погрузочная площадка, лесопогрузочный пункт

форвардер (самозагружающийся трактор для трелевки лесоматериалов в погруженном положении)

сучкорезка

сучок, ветка

машина для раскряжевки

хлыст

штабелевать, складывать штабелем

штабель

грузовик

колея, борозда

трелевочный волок

|

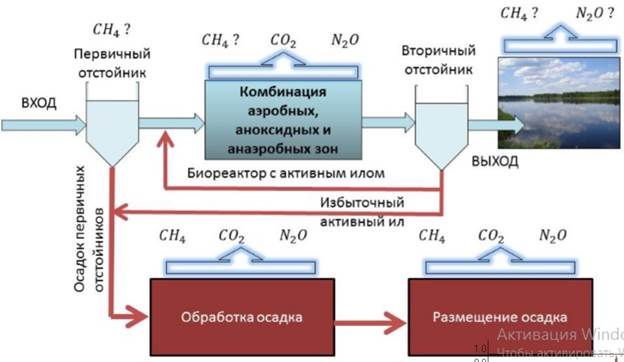

Around 1972, the tree length logging system was introduced and was a major advancement over the chain saw logging system. It uses several major pieces of equipment, needing only one labourer for each machine. One machine is a feller-buncher, which cuts trees at ground level and places them in bunches.

Another machine is a Skidder which drags the bunches to the landing. In most cases, two Skidders were needed to keep up with the feller-buncher. Alternatively, a forwarder machine (photo) could be used. At the landing, a delimber machine removes limbs from the trees. A slasher machine cuts the trees to appropriate lengths and stacks the logs in piles for truck transport.

The tree length system can be very productive, but only if the labourers are there for each machine, each machine was working, and the weather was not severe. If a labourer was missing or a machine down, production was brought to a halt. If the weather was severe, the different machines would cause ruts in the ground making it hard for the machines to move around. This was particularly problematic since the tree length logging system requires a network of roads, skidding trails, and landings.

Task 1 Назовите по-английски виды Лесных машин, перечисленных в этом тексте.

Task 2 Укажите функции Лесных машин.

HARVESTER

(Лесозаготовительная машина для валки или валки и обработки деревьев)

| felling

thinning

easy-to-reach controls

suspension

suspension design

harsh

roomy

dual

boom

stick

harversting head

extension

extend

require

handle

eliminate

swing

command

lever

hoist

consist of

two-section stick

box construction design

dual hoist cylinders

stick cylinder

extension cylinder

| рубка, валка (леса), заготовка леса, главные рубки

прореживание, вырубка

легкодоступные органы управления

подвеска, подвешенное состояние

подрессоренное, на рессоре

суровый, жесткий

просторный

двойной

стрела

рукоять

валочная головка, захватно-срезающее устройство

вылет (стрелы), выдвижение

удлиняться, выдвигаться

требовать

оперировать, манипулировать, сортировать

уменьшать

поворачивать

управление

рычаг

подъемник

(зд.) представляет собой

двухсекционный манипулятор

коробчатого сечения

два гидроцилиндра привода стрелы

гидроцилиндр привода рукояти

гидроцилиндр привода телескопической рукояти

|

Today’s logger must consider many different criteria in a harvester. Harsh forestry conditions require equipment with various applications and with high productivity. The Caterpillar Harvester line includes models designed and built to be used in various applications from first thinning to final felling and that are able to handle trees of different diametres.

The Caterpillar Harvester line has been engineered specifically to address operator comfort. All cabs have a roomy interior, easy-to-reach controls and a suspension design that eliminates vibration.

Easy-to-reach controls give the operator full finger tip command. The harvesting head and boom and stick functions, plus the cab rotation are controlled from these levers.

Boom and stick consist of a two-section stick with a box construction design that extends 2,5 meters. Boom incorporates dual hoist cylinders, stick cylinder and extension cylinder. The boom and stick swings with the cab and is mounted along the side of the cab.

P p p

| to adjust

pendulum arm

slope (sloping conditions)

directional travelling

armrest

to buck

hazard

to access

to aid

tight

adjustable armrest

| регулировать, приспосабливать

ручка, рукоятка, рычаг

уклон, наклон, скат

передвижение

подлокотник

раскряжевывать, распиливать

авария, несчастный случай, опасность, риск

получать доступ, добираться

помогать, обеспечивать вспомогательные средства

густой

регулируемый подлокотник

|

The operator may also adjust the pendulum arms to level the machine while harvesting. The pendulum arm suspension technology has revolutionized the industry. With this kind of versatility the operator can access trees in the tightest of thinning areas and toughest of sloping conditions.

Machine movement is controlled by floor peduls to free up the operator’s hands to maneuver the harvesting head with the boom and stick.

Excellent viewing area gives the operator a direct view of the harvesting head and the tree. The boom is mounted beside the cab, rather than directly in front. Windows are made of polycarbonate material to promote maximum protection for the operator.

Directional travelling is controlled by a floor pedul for easy changing of forward and reverse.

Operator ergonomics are improved through an eight-way adjustable seat, with seven-way adjustable armrests.

The computer aided bucking and measuring system is located in direct line-of-sight for easy viewing. A digital monitoring system displays all vital machine information and alerts the operator of potential hazards that could damage the harvester.

THE SHV RAPID EGS (ROTTNE INDUSTRI AB)

| single grip

to gain

wagon

to articulate

frame lock

stand

to distribute

entire

strip road

manual

light-footed

pendelum-arm system

terrain capability

leveling feature

to retain

brush

powered brush-saw

cleaner

loader (зд.)

reach

to cope

versatile

head

mounting kit

feed roller

trunk

grip

to delimb

| с одним захватом

получать

грузовая платформа

сочленять шарнирами, поворачивать

ходовая часть, рама

лесонасаждения, древостой

распределять

весь, целый

узкая лесосека, делянка

ручной

быстроходный

система рычагов

проходимость

подвеска

удерживать, сохранять

сучья

электрическая бензопила, сучкорезка

устройство для очистки

захват, грейфер

вылет стрелы (погрузчика, крана)

справляться

надежность

головка

набор инструментов

подающий ролик, ролик подачи, роликовый транспортер

ствол

захват, грейфер.

обрезать сучья

|

The SMV Rapid EGS is a harvester for exacting jobs, with all the attributes characteristic of a powerful single-grip harvester. The machine is equipped with a strong loader and stable chassis, which makes it excellent for handling trees in large-scale final felling. The basic model has 6 wheels, but will naturally gain greater stability as an 8-wheel model. The short, compact wagon chassis with double articulated frame locks forms an ideal base for RK 200 harvester loader, which has a very high lifting capacity.

With a stand-operating harvester, thinning is evenly distributed over the entire thinning area, and the strip road distance can be increased to just over 30 meters without additional manual felling. The Rottne 2004, stand-operating harvester, is narrow, compact, light-footed and flexible and has a unique pendelum-arm system that provides first-class terrain capability. Thanks to the leveling feature it is always possible to retain the machine width even in stony and very hilly terrain.

There is a great need for brush cleaning in young forest stands and that is mostly done manually with a powered brush-saw. There are no machines special built to do the brush cleaning mechanically, but the stand operating harvester Rottne 2004 can easily be changed to a cleaning machine. A cleaning head, a mounting kit and 4 big wheels are what is needed to convert the machine to a very efficient brush cleaner.

The Rottne 5005 is a highly efficient machine for both thinning and final felling. This harvester is compact, flexible and easy to manoeuvre, and also has a strong loader with excellent reach. Rottne 5005 has unique pendulum-arm system, and its advanced leveling function enables the machine to cope with very difficult terrain. This machine is easy to operate.

Rottne H-20 is primarily designed for final felling and large sized trees, but as it is versatile and easy to operate it can very well be used as a strip road operating harvester in later thinning. The powerful loader RK 200 and the unique design of the head EGS 700 with five feed rollers keep the trunks in a firm grip which is a benefit for delimbing and the measurement accuracy.

Task 1 Подберите к словам из левой колонки слова с аналогичным значением из правой колонки.

| 1. logger

2. machinery

3. to engineer

4. to develop

5. roomy

6. terrain

7. information

8. hazard

9. harsh

10. various

11. to mount

12. versatility

13. viewing

14. handling

| a) data

b) risk

c) loading

d) visibility

e) spacious

f) reliability

g) to install

h) to design

i) area

j) to improve

k) equipment

l) feller

m) different

n) severe

|

Task 2 Найдите лишнее слово и переведите его.

a) felling, harversting, handling, suspension, delimbing, thinning;

b) logger, operator, harvester, loader, terrain, cleaner, delimber;

c) various, roomy, final, dual, unique, hilly, narrow.

Task 3 Назовите по-английски назначение Харвестеров различных марок

Task 4 Переведите предложение на английский язык

1. Харвестеры используются для валки и прореживания леса.

2. Оператор может видеть валочную головку и дерево из кабины.

3. Валочная головка, стрела и рукоять управляются легкодоступными органами управления.

4. Стрела с рукоятью установлена сбоку кабины.

5. Окна из тонированного стекла защищают оператора.

6. Регулируемое кресло и регулируемые подлокотники обеспечивают комфорт для оператора.

7. Харвестер марки Rottne H-20 способен работать на узких лесосеках, так как им легко управлять.

FELLER BUNCHER

(Валочно-пакетирующая машина)

ML-135 --- a new development of CNSIME

| to attend

perfection

capacity

manipulator reach

ground clearance

ground pressure

shear-and-grapple device

good resource

propulsion

turntable

clearance

positioning

lattice

fatigue

conduits (зд.)

| заботиться

совершенствование

мощность

вылет стрелы манипулятора

дорожный просвет

давление на грунт

захватно-срезающее устройство

повышенный ресурс

сила тяги, движущая сила

поворотный стол, поворотная платформа

расчистка, просека, вырубка

установка

решётка

усталость

насосы

|

CNSIME traditionally attends to creation and perfection of the feller-bunching machines. The machine, which is carrying out the most dangerous and labour-intensive operation on cutting area, is worthy of it. All process of timber cuttings depends on its efficiency and an opportunity to realize the technical parameters.

CNSIME has developed and produced the first pre-production model of this machine. The main parameters are following:

b Capacity, h.p. – 225

b Productivity, trees / hour – 170

b Maximal diameter of the tree cut, sm – 56

b Maximal manipulator’ reach, m – 8…9,4

b Ground clearance under the chassis, mm – 600

b Ground pressure, kg/sm2 – 0,39

Dynamical, manipulating machine with a low ground pressure is focused on the consumers working with the trees of not large diameter. An opportunity to collect in shear-and-grapple device up to five trees of 20 sm in diameter provides the machine’ productivity up to 170 trees/h.

Powerful diesel AMZ-238 with a good resource, blocked with pump group provides good dynamics and propulsion performance characteristics of the machine. The integration of the turntable allows carrying out rotation with the working equipment and cutting trees in a corridor “on clearance” 5 m. The machine is equipped with one of the best in the world proportional electrohydraulic control system produced by “Danfoss”. Softness and accuracy of the positioning do not demand significant efforts of the operator.

The comfortable, well-protected cabin with the increased visibility and without “traditional” lattices reduces fatigue of the operator. The modern supervising and diagnostic equipment blocked in a monoblock with display of the current data to the liquid – crystalline display provides the operator with the necessary information.

The hydrosystem of the machine is produced with application of conduits for ultrahigh pressure.

The modern technologies of mechanical engineering provide good quality of the machine.

NEW PRODUCTS

New Hydro-Ax Feller Buncher

| saw

softwood

plantation

to accumulate

arm

tilt

steering

roller bearing

joint

rugged

windshield

stump

felling head

tight

stand

saw’s pocket

bundle

| пила

хвойные породы деревьев

насаждения

складываться

стрела (крана)

наклон

рулевое управление

шарикоподшипник

соединение

прочный, массивный

щит от ветра

пень

валочная головка, захватно-срезающее устройство

густой

древостой, лесонасаждение

накопитель механизма срезания

пакет, пачка

|

The Forestry and Industrial Equipment Division of Blount Inc. has introduced the newest feller buncher in the Hydro-Ax line, the Hydro-Ax 470. The 470 is packed with a new Hydro-Ax 20 high capacity saw for optimum productivity in softwood thinning on pine plantations. The Hydro-Ax 470 tractor has a new hydraulic system that runs accumulating arm, lift, tilt and steering functions simultaneously. The roller bearing center joint is a rugged design that improves wear life and enhances reliability. Visibility is exceptional with a wide view curved windshield and large skylight, allowing the operator to see the full tree from stump to treetop. The design of the felling head also provides good see-through visibility. The Hydro-Ax 20HC saw has a compact design for tight thinning stands and the capability of bunching 6 sq. ft. of wood. The saw’s pocket design allows for bundles to be held tightly, keeping stems straight.

Deere 753G / 753GL

| tracked

regeneration felling

tailswing

unwinding

turbocharged diesel engine

torque

solid power (зд.)

heavy-duty

one-piece

undercarriage frame

to feature

rear

tinted

| гусеничный

лесовосстановительные рубки

задний поворот

раскатка

дизельный двигатель с турбонаддувом

вращательный момент

повышенная мощность

высокопроизводительный, предназначенный для тяжелого режима работы

монолитный

ходовая часть

отводить важную роль

задний

затененный

|

“John Deere” announces their new 753G / 753GL tracked feller bunchers and harvesters, excellent for regeneration felling, selective cuts or thinnings. The 753G / 753GL get into tight places with near-zero tailswing and 360-degree continuous rotation with no swing stops and no unwinding. The new Deere 6081H turbocharged diesel engine has the high torque and solid power through the entire working range to improve production in any operation. The engine puts out a mighty 241 horsepower. The 753G / 753GL have a heavy-duty one-piece undercarriage frame. They also have a 30-inch ground clearance. They feature box construction on the boom and arm for more strength and longer life; large, tinted polycarbonate windows, including a sliding rear window with insect screen, provide visibility to the head and the treetops.

SKIDDER

(Трелевочник, трактор для трелевки лесоматериалов волоком или в полупогруженном положении)

| to handle

logger

to attain

swing boom

grapple

terrain

dozing

to deck

blade

feature

track

pulling power

performance

to skid

balance

heavy-duty

optional (зд.)

winch

cable skidding

steep

arch

bunching grapple

tire

Loading Sensing Hydraulic System

displacement

to brake

steering

grab

to adjust

tong

Auto-Grab feature

| выполнять

лесоруб

достигать, добиться

качающаяся стрела (трелевочного трактора)

грейфер, захват

территория

дозирование

штабелировать

толкатель, отвал, нож, щит, бульдозерная навеска

приспособление

гусеничная лента

тяговая сила, сила тяги

производительность

трелевать

баланс, равновесие

предназначенный для тяжелого режима работы, высокопроизводительный

дополнительный

лебёдка

канатная трелевка, трелевка леса канатными установками

крутосклонный

трелевочная арка (оборудование к трелевочному трактору для подъема передних концов трелюемых материалов)

пакетирующий грейфер

шина

адаптивный манипулятор (чувствительный к нагрузкам)

производительность (насоса)

тормозить

рулевое управление

захват

регулировать

клещи, захват

автозахват

|

The Cat 527, 515 and 525 Skidders can easily handle a variety of tasks and applications for today’s loggers. Maximum skidding performance is best attained through the available swing boom and grapple. This tool is ideal for locations with soft terrain. High horsepower and torque enhance the 527’s dozing abilities. The blade offers high levels of versatility in dozing and decking applications Expanded track options allow the 527 to maintain skidding performance and minimize ground disturbance. Superior balance and pulling power enable the 527 to skid large loads with the optional 527 winch. This highly productive winch has been specifically designed for the 527 skidder in steep and mountainous skidding applications.

Excellent skidder balance, plus the powerful mechanically driven, heavy duty skidding winch provides outstanding 515 and 525 cable skidding performance. Expanded tire options allow the 515 and 525 to maintain skidding performance in a wide range of ground conditions. The 525 is available with swing boom and grapple. With excellent balance and outstanding visibility, the 525 with swing boom is an ideal tool for very rough or soft terrain, thinnings, and select cuts. The 525 has the horse power and wheelbase to handle dual function arch and large capacity bunching grapples.

Load sensing Hydraulic system improves skidding performance and efficiency. Load Sensing hydraulics utilize a load sensing variable displacement pump and pressure compensating system, which continually monitors braking, steering, and grapple hydraulic power requirements. The Auto-Grab feature from Cat constantly monitors and adjusts tong pressure as needed to securely hold grapple loads while skidding.

FORWARDER

(форвардер, самозагружающийся трактор для трелёвки лесоматериалов в погруженном положении)

| The all-round forwarder RAPID

|

| 8WD

wagon

loader

rigid

articulated

frame

gravity

detachable load bunk

clam dunk skidder

lime spreader

container carrier

sturdy

well-dimensioned

traction

positioning

steering angle

joint

tracking

profile

tyre (tire)

ultimate

log-hauling

ground clearance

facility

| восьмиколесный, привод для 8 колес

грузовая платформа

грейфер, захват

жесткий, устойчивый, неподвижно закрепленный

шарнирно-сочлененный, шарнирный, поворотный

ходовая часть, рама

сила тяжести

съемный грузовой коник

трактор со стрелой и коником с зажимными рычагами (для бесчокерной трелевки)

разбрасыватель (распределитель) извести

кузов для перевозки тары

сильный, крепкий

правильно рассчитанный

тяга, тяговое усилие, сцепление, сила сцепления

установка

угол поворота

соединение, стыковка

регулирование

профиль

шина

основной, конечный, окончательный

трелевка, транспортировка, вывозка хлыстов

дорожный просвет

оборудование

|

Over the years the Rapid has established itself as a very simple, reliable and all-round forwarder. The equipment range includes 8WD, rigid or articulated wagons and two types of loader. The rigid wagon, which is available in different frame lengths, has a very low center of gravity and detachable load bunks. This means that the wagon can be changed quickly and easily from forwarder to other fields of application such as clam bunk skidder, container carrier etc.

MATERIAL HANDLER

(Погрузчик материалов)

| boom

drop nose stick

outrigger

counterweight

hydraulic circuit

tire

option

scrap

waste handling package

mesh radiator

cab riser

customer

log

to ship

| стрела

опущенная вершина рукояти

аутригер (для увеличение площади опоры)

противовес

гидравлика

шина, пневматическое колесо

дополнительное оборудование

отходы, обрезки

блок погрузки отходов

сотовый (сетчатый) радиатор

подъемник кабины

заказчик

хлыст, бревно

грузить

|

M 318 and M 320 Material Handlers combine the versatility of a wheel excavator with the specific purpose of a material handling machine.

Standart MH models offer a straight boom, a material handling drop nose stick and extended outriggers. The M 320 MH also has a 600 kg additional counterweight.

“Heavy lift” hydraulic circuit and solid tires are available as options. Solid tires are recommended in a scrap handling applications.

Other options such as the waste handling package and large mesh radiator help maintain a cleaner cab and radiator in waste application and dusty conditions.

M 318 and M 320 Material Handlers can be available with fixed cab riser or with hydraulic cab riser.

A fixed cab riser is offered for standard and material handling machines, where a high viewing position is needed. It can lift the cab by 1,2 m.

A hydraulic cab riser is designed to meet customers’ needs for easier operation and greater stability. It provides high flexibility in cab hight. Hydraulic cab riser in the top position raises the cab by 2,0 m. This provides optimal viewing to all sides in different applications such as log handling, scrap handling and various load / unload tasks. In medium position the hydraulic cab riser places the cab forward by 0,5 meters more than in the travel position, for increased visibility. In bottom position it is used for shipping and travelling.

| Hydraulic cab riser in the top position

| Hydraulic cab riser in medium position

| Hydraulic cab riser in bottom position

|

Task 1 Назовите по-английски, какое технологическое оборудование используется на погрузчиках марки М318 и М320?

Task 2 Вставьте пропущенные буквы и переведите слова:

Ve…sat…lity, w…eel, e…cavat…r, p…rpose, outr…g…er, co…nter…eight, hydr…ulic, cir…uit, pac…age, a…pli…ation, fle…ibi…ity, vi…wing, t…re.

Task 3 Ответьте на вопросы по тексту.

1. What factors do M318 and M320 combine?

2. When are solid tires for material handlers recommended?

3. What helps maintain a cleaner cab and radiator?

4. What kind of cab riser can M318 and M320 have?

5. How high can a fixed cab riser lift the cab?

6. How high can a hydraulic cab riser lift the cab?

7. How can visibility from the cab be increased?

INTEGRATED TOOLCARRIER

(Погрузчик со сменным рабочим оборудованием)

| fragile

regulations

refinement

piston

fuel combustion

ratio

fan

sound suppression package

refrigerant

to spill

drain

utility

bucket

material handling

silicon

joint

switch

lever

The Quick Coupler

Hydraulic valve

to engage

| хрупкий, ломкий, слабый

правила, инструкция

очищение, обработка, усовершенствование

поршень

сгорание топлива

коофициент

вентилятор

устройство подавления звука

охлаждающее вещество, охладитель

проливать, расплескивать

дренаж

бытовой, связанный с коммунальными услугами

ковш

погрузка материалов

кремний

соединение, узел

переключатель

рычаг

устройство для быстрой сцепки

гидравлический клапан

зацеплять, соединять

|

Caterpillar machines help maintain and preserve the fragile environment.

The IT28G is designed to provide more performance than ever before in a machine of this size. That means more work done in a day, less fuel consumed and minimal impact on our environment.

The IT28G uses the Cat 3116T low emission engine. This engine is designed to meet the world’s toughest emission regulations. Refinements to the turbocharger, cylinder head and pistons improve fuel combustion so there are less emissions. Plus there is a new system that closely controls fuel-to-air ration to help burn fuel efficiently and cleanly.

The IT28G’s new engine cooling system allows the engine to be fully enclosed so less engine noise escapes. Not only does the operator notice a significant drop in machine sound levels inside the cab, but spectators outside hear less noise too. The cooling fan traditionally a major contributor to noise, is now hydraulically driven. The result is cool, quiet operation with less disturbance to the environment. And IT28G is even quiter with the optional sound suppression package.

To help protect the earth’s ozone layer, the IT28G’s air conditioning unit uses only R-134 refrigerant which does not contain harmful chloro-fluorocarbons (CFC’s).

Engine oil, transmission and hydraulic filters are positioned vertically and are easy to reach so they can be removed without spilling. Lubricant filters and drains are also designed to minimize spills.

The IT28G offers excellent performance in a wide variety of applications such as bucket loading, material handling, utility work and industrial support.

Operator station is designed for total control in a comfortable, spacious environment. All control levers, switches and gauges are positioned to maximize comfort and productivity. Two-door cab offers exceptional ventilation and easy entry and exit. Full-length glass windshield with silicone joints enhances visibility.

The Quick Coupler is an integral part of the Caterpillar Integrated Toolcarrier. Tool changes are quick and easy. Activation of a third hydraulic valve to engage and disengage attachments is a simple lever movement from the operator seat.

The Quick Coupler is an integral part of the Caterpillar Integrated Toolcarrier. Tool changes are quick and easy. Activation of a third hydraulic valve to engage and disengage attachments is a simple lever movement from the operator seat.

KNUCKLE BOOM LOADER

(погрузчик с шарнирно-сочлененной стрелой)

| platform frame

loading

attachment

option

fifth-wheel trailer

pull-through delimber

topping saw

continueous rotation grapple

four-stroke

stroke

power stroke

service point

altitute

jacket water aftercooler

aftercooler

piston ring

air intake

unit injectors

radius cone injector nozzle

cylinder head sleeve

warning monitor

tightness

fuel pre-filter

water separator element

integral pilot controls

engine service hour meter

gauge

coolant

| грузовая платформа

погрузка

приспособление, скрепление, рабочий орган, рабочее оборудование

дополнительное рабочее оборудование

четырехколесный трейлер с 5 м запасным колесом

технологическое оборудование для обрезки сучьев, сучкорезка

устройство для срезания (обрезки) вершин деревьев

захват (грейфер) с неограниченным углом поворота (с ротором)

четырехтактный

ход

рабочий ход

агрегат

высота

водяной радиатор (теплообменник)

вторичный холодильник, дополнительный охладитель

поршневое кольцо

воздухозаборник

инжекторы

штифтовая форсунка (с конусным отражателем на конце иглы)

гильза головки цилиндра

аварийное табло

плотность

топливный префильтр (предварительной отчистки)

водно-отделительный элемент

совмещенные рукояти управления

счетчик моточасов

измерительный прибор, калибр

охладитель

|

Structures

The 539 Knuckle boom loader’s main structures (main frame, platform frame and boom and stick) are purpose-built for the stress loads of pull-through delimbing and truck loading.

Attachments

Factory installed options include a fifth-wheel trailer, pull-through-delimber with topping saw, continueous rotation grapple etc.

Engine

The turbocharged and aftercooled Cat 3126 DITA engine provides optimum power and fuel efficiency. The four-stroke cycle design delivers long power strokes and efficient fuel combustion with low emissions. The engine is easily maintained. All engine service points are located on the back side of the engine and are easily accessed through swing-out doors at the back of the loader. Turbocharger enhances performance and engine efficiency, especially at high altitudes by packing more air in the cylinders for excellent combustion. Jacket water aftercooler reduces smoke and emissions by providing a cooler, more efficient combustion. This also extends the life of the piston rings.

Air intake heating eases cold weather starting. Individual, high-pressure unit injectors increase fuel economy with low emissions. The radius cone injector nozzle provides excellent contact with the cylinder head sleeve to ensure tightness with the combustion chamber.

Fuel pre-filter and water separator element combined with two high efficiency micron filters ensure excellent fuel cleanliness, provide long injector life, fuel system durability, and protection.

Operator’s Station is designed for comfort, safety and ease of operation. It has such features as an ergonomic seat, integral pilot controls and excellent sight line to the work area.

Caterpillar instrument panel includes: engine service hour meter; voltmeter; gauges for hydraulic oil temperature, fuel level, engine oil pressure, coolant temperature; a two-stage system warning monitor.

Task 1 Сопоставьте слова из левой колонки со словами из правой колонки и переведите их.

| 1. Knucle

2. Platform

3. Truck

4. Topping

5. Power

6. Fuel

7. Service

8. Swing-out

| a) combustion

b) loading

c) stroke

d) doors

e) boom

f) points

g) frame

h) saw

|

|

|

|

| 1. piston

2. air

3. cylinder

4. combustion

5. fuel

6. ergonomic

7. instrument

8. hour

9. warning

| a) intake

b) rings

c) panel

d) meter

e) chamber

f) monitor

g) system

h) seat

i) head

|

Task 2 Подберите к словам под буквой «а» слова с аналогичным значением под буквой «b» и переведите их.

A: truck, attachments, to enhance, performance, altitude, to extend, to ensure, protection.

B: to strengthen, efficiency, lorry, to garantee, hight, to continue, guarding, features.

Task 3 Ответьте на вопросы по тексту:

1. What are the purposes of the 539 Knuckle boom loader?

2. What are the main structures of the 539?

3. What attachments has the 539?

4. What type of engine does the 539 have?

5. What are the advantages of the engine?

6. What and how enhances the engine performance at high altitudes?

7. What and how helps reduce smoke and emissions?

8. What eases engine starting in cold weather?

9. What provides fuel economy?

10. Why can we say that operator's station is comfortable?

11. What does the instrument panel include?

SKID STEER LOADER

(Погрузчик с бортовым поворотом)

| power train

robust flywheel torque

closed loop

output

hydrostatic system

anti-stall

wheel

strength

prestressed

oil bath

lubrication

drive axle

forged

induction-hardened

sealed

parking brake

spring-applied

to release

features

joystick controls

padded armrests

adjustable

to contour

coupler

| силовая передача

постоянный крутящий момент махового колеса

круг циркуляции жидкости

напряжение

гидростатическая силовая передача

срыв потока, потеря скорости при срыве потока

колесо

прочность

предварительно-напряженный

масляная ванна

смазка

ведущий мост, ведущая ось

кованый

специально закаленный

плотно закрытый, запечатанный, загерметезированный

стояночный тормоз

включающийся с помощью пружинного механизма

растормаживать

приспособления

рукояти управления

мягкие подлокотники

регулируемый

контурировать

устройство быстрого соединения механического типа

|

The 216 and 226 Skid Steer Loaders are highly versatile compact construction machines. They are designed to deliver traditional Cat reliability and productivity in the toughest working conditions.

Power train Caterpillar 3034 engine provides high engine horsepower and robust flywheel torque. Closed loop, high-output hydrostatic system and exclusive anti-stall system deliver maximum torque to the wheels. High-strength, presstressed chains run in an oil bath for continueous lubrication. Each drive axle is forged, induction-hardened and sealed for life. Parking brake is spring-applied and hydraulically-released.

Operator Station is very comfortable. Ergonomic features such as low-effort joystick controls, a comfortable padded armrest and an adjustable, contoured seat reduce operator fatigue. The loader arms, quick coupler and cab are all designed to provide excellent visibility to the work tool.

Task 1 Найдите лишние слова и переведите их.

a) comfortable, low, important, close, toughest, high, versatile

b) construction, versatile, engine, feature, armrest, fatigue, axle

c) flyweel, lubrication, joystic, fatigue, brake, torque, wagon, bunk

Task 2 Сопоставьте слова из правой и левой колонок

| 1. compact

2. traditional

3. working

4. high

5. hydrostatic

6. forged

7. parking

8. ergonomic

9. adjustable

| a) system

b) axle

c) horsepower

d) brake

e) features

f) conditions

g) reliability

h) seat

i) construction

|

Task 3 Переведите предложения на английский язык

1. Погрузчик с бортовым приводом модели 216 – очень надежная машина.

2. Известно, что погрузчики с бортовым приводом предназначены для работы в тяжелейших условиях.

3. Стояночный тормоз включается с помощью пружинного механизма, а растормаживается гидравлически.

4. Удобные мягкие подлокотники и регулируемое кресло уменьшают усталость оператора.

5. Конструкция кабины обеспечивает прекрасную обзорность.

TREE SHEAR

(Ножевое устройство для срезания деревьев)

| to maintain

to manage

track mounted skid steer loader

deseased

hazardous

reduction

growth

undergrown

forest floor

grapple arm

to grab

shear blade

tensile steel

to sharpen

hose

plated pivot pin

hard-line

bushing

to align

bunch

shearing cylinder

haudraulics

bore

stroke

rod

auxiliries

seal

Accumulator Arm

| поддерживать

управлять

гусеничный погрузчик с бортовым приводом

больной

опасный

снижение

рост

подлесье, подлесок

лесной покров, лесная подстилка

стрела

захватывать

нож,ножевое полотно

прочная на разрыв (растяжение) сталь

заострять

шланг

пластинчатая вращающаяся ось (ось вращения)

жесткий, твердый

втулка, вкладыш, переходной фитинг

контировать, выравнивать, производить разбивку, трассировать

связка, пачка

гидроцилиндр привода ножей (бесстружечного резания)

гидравлика

объем цилиндра

ход

стержень

вспомогательное оборудование

сальник

накопитель

|

| |

| |  |

Dymax 10'' and 14'' Timberwolf Series Tree Shears can be found working all over the world maintaining and managing natural forests. Dymax Timberwolf Tree Shears are particularly popular on track mounted skid steer loaders working in U.S. Forest Service Land, where many districts recommend Dymax models as being ideal for maintaining and managing natural forests.

Small machines with Dymax Timberwolf Tree Shears are perfect for removing diseased trees, dead treees and for hazardous fuels reduction. This allows more room for growth of remaining trees while removing the undergrowth helps prevent the spread of forest fires. Disturbance to the floor is minimized when using Dymax Timberwolf Tree Shear on a track mounted Skid Steer Loader.

FEATURES

Dymax 10'' and 14'' Forest Timber wolf Tree Shears feature

· Rugged, durable solid steel grapple arms securely grab the tree

· Near Ground Level Cutting

· Replaceable shear blades comprised of high tensile steel and can easily be sharpened

· Extremely powerful shearing cylinders

· Convenient hose routing to hard-line shearing cylinders

· 3'' chrome plated pivot pins and replaceble CATERPILLAR® bushings and seals

· Blade adjustment and stop mechanism which allows blades to be realigned anywhere in the field

· Optional Accumulator Arm – for bunch cutting trees

SPECIFICATIONS for Skid Steer Loaders

| Timberwolf Model

| Shearing Cylinders

| Weight (in.)

| Height (in.)

| Width (lbs.)

| Recommended Hydraulics

|

| 10'' Timberwolf

|

4'' Bore

8'' Stroke

2'' Rod

|

|

45.47

|

54.60

|

Standard Auxiliaries

|

| 10'' Timberwolf with Accumulator

|

4'' Bore

8'' Stroke

2'' Rod

|

|

45.47

|

54.60

|

Standard Auxiliaries and 4th function

|

| 14'' Timberwolf

|

5'' Bore

10'' Stroke

3'' Rod

|

|

60.00

|

66.00

|

Standard Auxiliaries

|

| 14'' Timberwolf with Accumulator

|

5'' Bore

10'' Stroke

3'' Rod

|

|

60.00

|

66.00

|

Standard Auxiliaries and 4th function

|

Task 1 Выпишите из текста и переведите словосочетания с существительными tree, forest.

Task 2 Выпишите “ing – forms”, определите часть речи и функцию в предложении и переведите на русский язык.

Task 3 Выпишите Participle II, определите функцию в предложении и переведите на русский язык.

WHEEL LOADER

(Колесный погрузчик)

| breakout force

durability

aftercooler

direct injection

rated

rpm (revolutions per minute)

flywheel

four-stroke cycle

direct injected fuel system

to lug back

deep skirt engine block

rigidity

plugging

consumption

solution

| сила прорыва, прокатки (полосы)

долговечность, прочность

дополнительный охладитель, вторичный холодильник

непосредственный (прямой) впрыск

расчетный, номинальный

оборотов в минуту

маховое колесо, маховик

четырехтактный цикл

система питания дизельного двигателя с непосредственным (прямым) впрыском

снижать обороты

моноблочная конструкция двигателя со вставными гильзами и поршнем с удлиненной юбкой

прочность, жесткость

закупоривание

потребление

решение

|

The wheel loader 966G Cat is designed to deliver excellent breakout force, fast load, precise maneuvering and comfort. Its durability is proven by field-testing. Its six-cylinder, direct injection, turbocharged and aftercooled DITA Engine is powerful, reliable, easily maintained and with low emissions. The engine delivers, at the rated speed of 2200 rpm, the flywheel power of 175 kw (235 hp). Four-stroke cycle design delivers long power strokes, efficient fuel combustion with low emissions, and excellent fuel economy. The direct injected fuel system provides a controlled fuel delivery increase as the engine lugs back from rated speed. This results in increased horsepower above rated power. Deep skirt engine block design ensures rigidity and reduces vibration. Cooling system features a hydraulically driven fan for less radiator plugging, lower noise levels and reduced fuel consumption (by 3% to 5% or more).

The 966G cab is a spacious and comfortable work environment that promotes productive operation. The cab includes outstanding viewing area, ease of service, ergonomic design and controls placement, improved ventilation and generous storage areas.

Task 1 Найдите в тексте и переведите сочетания со словами “force” и “power”.

Task 2 Какие слова и выражения говорят об отличных характеристиках the 966G Cat?

Task 3 Найдите в тексте однокоренные слова для следующих слов и переведите их.

Maneuverability, comfortable, during, turbocharger, aftercooler, power, reliability, to emit, delivery, rate, designer, efficiency, economical, rigid, to vibrate, to cool, to radiate, to consume, to operate, space, to produce, to place, to store, to solve.

Task 4 Ответьте на вопросы по тексту.

1. What types of loaders do you know?

2. What kind of engine has the wheel loader 966G Cat?

3. What flywheel power can the engine deliver?

4. What are the advantages of the engine?

5. What reduces vibration of the engine?

6. What feature helps reduce radiator plugging, noise and fuel consumption?

7. Why is the operator's cab considered to be comfortable for productive operation?

GRAMMAR EXERCISES

Infinitive

I. Infinitive as a Subject

1. To know different types of Forest Machines and their operational principles is necessary for Logging Equipment engineers.

2. To delimb a tree means to remove the limbs from it.

3. To know the technical parameters of machines is important for a qualified engineer.

4. To place trees in bunches is possible with the use of Feller-Bunchers.

5. To manage the engine with the Electronic Control System is to maximize the machine performance.

6. To make the Operator Station quiter is to reduce the sound level inside the cab.

7. To skid logs is to drag them to the landing.

8. To buck trees is to cut them into appropriate lengths.

9. To stack logs means to put them into piles.

II. Infinitive as an Attribute

1. Metal to be used for main frames of Forest Machines must be very strong.

2. The new Wheel Loaders to be produced at this plant are designed for work in forest conditions.

3. The working environment to provide comfortable work for the operator should be well-organised.

4. The parts of the Excavator to be constantly lubricated are easily accessed.

5. Large windows to be an integral part of a Forest Machine cab provide excellent viewing.

6. The machine to remove the limbs from trees is called a Delimber.

7. A device to grab logs is called a grapple.

8. A machine to work in forest applications is called a Forest Machine.

9. A machine to transport logs to the landing is called a Skidder.

III. Infinitive as an Adverbial Modifier

1. To meet the needs of most Forest Machine applications there are four factory counterweight options.

2. Caterpiller Skid Steer Loaders are designed to work in the toughest forest conditions.

3. To lift or to low the cab the operator regulates the cab riser.

4. Forest Machines should be designed to meet different needs of forest industry.

5. To extend service life guarding is used in Caterpiller machines.

6. To save time and money simplified service and maintenance features were used in the machine.

7. To make entry and exit easier the cab has two doors.

8. The operator may adjust the pendulum arms to level the machine.

9. Skidder is designed and built to skid trees and stems to the landing.

IV. Infinitive as a part of Predicate with such a subject as “plant”, “aim”, “task”

1. Their first plan was to make soft thinning on pine plantation.

2. The aim of the experiment was to test the new model of the Road Builder in forest applications.

3. The task of the manufactures is to provide loggers with reliable logging equipment.

4. The aim of Forest Machine designers is to built a comfortable, well-protected cab with excellent visibility.

5. The task of the logger was to make selective cuts.

6. Our purpose is to make detailed comparisons of the loaders and then to buy the best one.

7. The purpose of a Feller-Buncher is to cut trees and to place them into bunches.

8. The task of the Skidder operator is to drag the bunches to the landing.

9. The designers task is to increase the efficiency of the machine.

V. Infinitive as a part of Predicate with other subjects but such as “plan”, “aim”, “task”

1. The comfortable, well-protected cabin with the increased visibility is to reduce fatigue of the operator.

2. A suspension design of the cab is to reduce vibration.

3. Floor peduls are to free up the operator’s hands.

4. A new engine system to control fuel-to-air ration is to reduce emissions.

5. Automated climate control is to maintain constant temperature in the cab.

6. Operator Station is to be constructed for comfort and ease of operation.

7. Road builders are to be built with different attachments to fit different forest road jobs.

8. The cabin is to be constructed to deliver excellent visibility of the area.

9. Joystics, padded armrests and adjustable seat to help reduce the operator fatigue are to be considered in cab design.

10. To prevent the spread of forest fires the undergrowth is to be removed.

11. Every Forest Machine is to be equipped with a cab riser to increase operator effectiveness.

VI. Subjective Infinitive Contruction

1. Forest Machines are known to be specially built for different forest applications.

2. Heel booms are considered to be especially suitable for loading sawlogs with large diameter.

3. The modern technologies of mechanical engineering are certain to provide good quality of Forest Machines.

4. The Hydro-Ax 470 Feller-Buncher is said to provide maximum productivity in soft wood thinning.

5. Turbochargers are considered to enhance performance and efficiency of an engine.

6. Small machines with tree shears proved to be more efficient to remove deseased and dead trees.

7. The cab climate appeared to be automatically controlled

8. The conditioning system of this type is likely to fresh air in the cab better.

9. Each of the levers appeared to be positioned within easy reach of the operator.

10. This machine seems to be highly productive.

11. A slasher machine is known not only to cut trees to certain lengths but to stack the logs in piles.

12. The modern technologies of mechanical engineering are supposed to provide good quality of Forest Machines.

13. The SMV Rapid is well-known to be very reliable Forwarder.

14. Material Handlers are known to have a fixed or a hydraulic cab riser.

15. Caterpiller machines are sure to maintain and preserve the environment.

VII. Objective Infinitive Construction

1. We know Caterpillar to produce different types of Forest Machines.

2. We supposed the Material Handler to speed up our work.

3. Operators wanted the cab to be roomy, comfortable and quite.

4. I heard him work in a large logging company.

5. We know them develop new disk saw.

6. I made him start the engine.

7. The manufacturers expected the new Harvester to be highly productive in thinning and felling.

8. I saw the seat and the armrests be easily adjusted.

Participle I

I. Participle I as an Attribute

1. Forest Machines being designed for work in tough forest conditions must have reinforced car body, rugged swing bearing, heavy doors and extra guarding.

2. Caterpiller Road Builders being equipped with various booms, sticks and grapples fit different forest road jobs.

3. Cabins being well-protected and comfortable reduce the operator fatigue.

4. Logging Equipment engineers must know the types of Forest Machines being used in Forest industry.

5. The Skidders being tested in our research institute can work in cutting areas with stumps and brushwood.

6. The technologies being introduced in our plant provide good quality of the machines.

II. Participle I as an Adverbial Modifier

1. Being equipped with grease lines lubrication points can be easily lubricated.

2. Being packed with high capacity saw the new Feller-Buncher can be used in softwood thinning on pine plantations.

3. Being primarily designed for final felling and large seized trees Rottne H-20 Harvester can also operate on strip roads for later thinning.

4. Being initially built for thinning the Forwarder can also be used for small-scale felling.

5. Having cut the trees at ground level a Feller-Buncher places them in bunches.

6. Having designed an adjustable seat, padded armrests and easy-to-reach joystics the designers created good working environment for the operator.

7. Having considered all advantages and disadvantages of the Tracked Loader the manufacturers put it into operation.

8. Having been made from polycarbonate material the windows promoted maximum protection for the operator.

9. Having been tested on water-logged soft grounds the Skidder was put into operation.

III. Participle I as a part of an Absolute Participle Construction at the beginning of the sentence.

1. A Feller-Buncher having cut and bunched the trees, a Skidder drags the bunches to the landing.

2. A Delimber machine having delimbed the limbs, a slasher machine bucks the trees.

3. A digital monitoring system having displayed the machine information, the operator could escape damage.

4. The saw pocket being installed to a Feller-Buncher, bundles are held tightly.

5. Large windows having been designed in the cab, the operator can see the tree from stump to top.

6. The turbocharged diesel engine having been installed to the Tracked Feller-Buncher, the production was increased.

7. The Harvester having been leveled, the operator continued harvesting.

IV. Participle I as a part of an Absolute Participle Construction at the end of the sentence.

1. There are no machine specially built for mechanical b

(Система машин заготовки хлыстов)

(Система машин заготовки хлыстов)

The Quick Coupler is an integral part of the Caterpillar Integrated Toolcarrier. Tool changes are quick and easy. Activation of a third hydraulic valve to engage and disengage attachments is a simple lever movement from the operator seat.

The Quick Coupler is an integral part of the Caterpillar Integrated Toolcarrier. Tool changes are quick and easy. Activation of a third hydraulic valve to engage and disengage attachments is a simple lever movement from the operator seat.